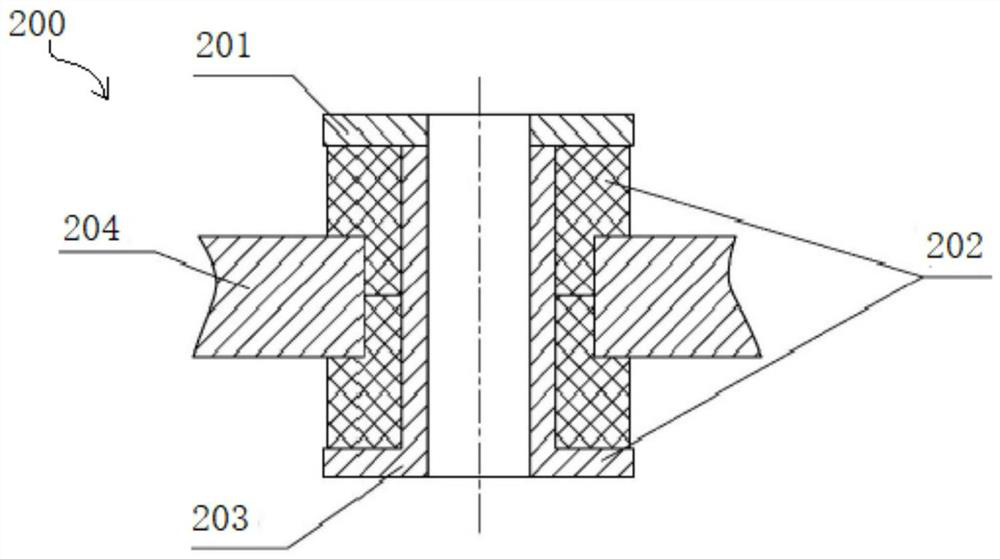

Novel three-dimensional shearing type shock absorber

A technology of shear type and shock absorber, which is applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problems of poor designability, large magnification, tension and compression deformation, etc., and improve the mechanical environment , the effect of reducing the magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

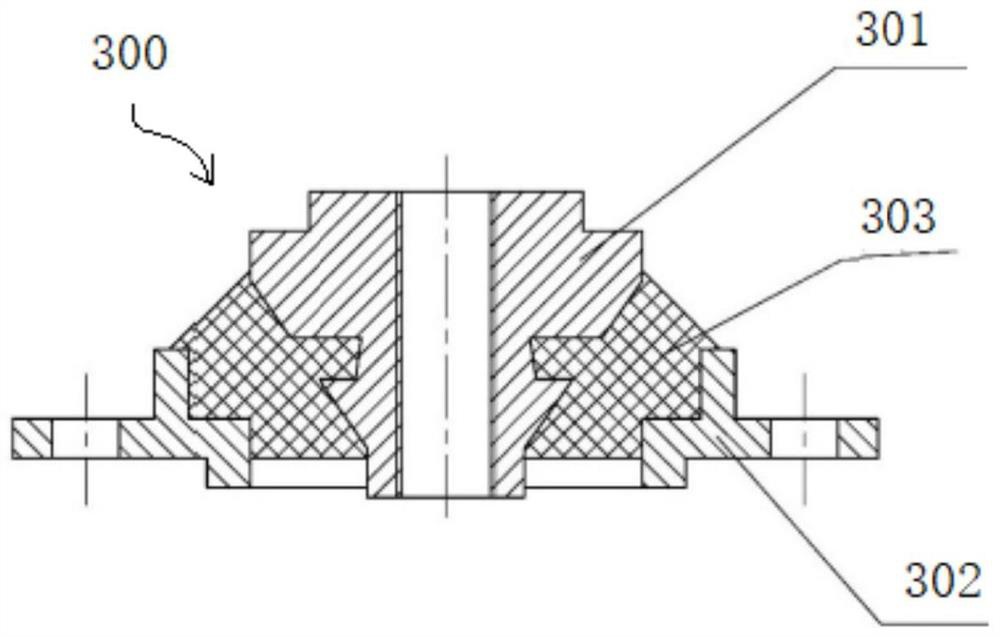

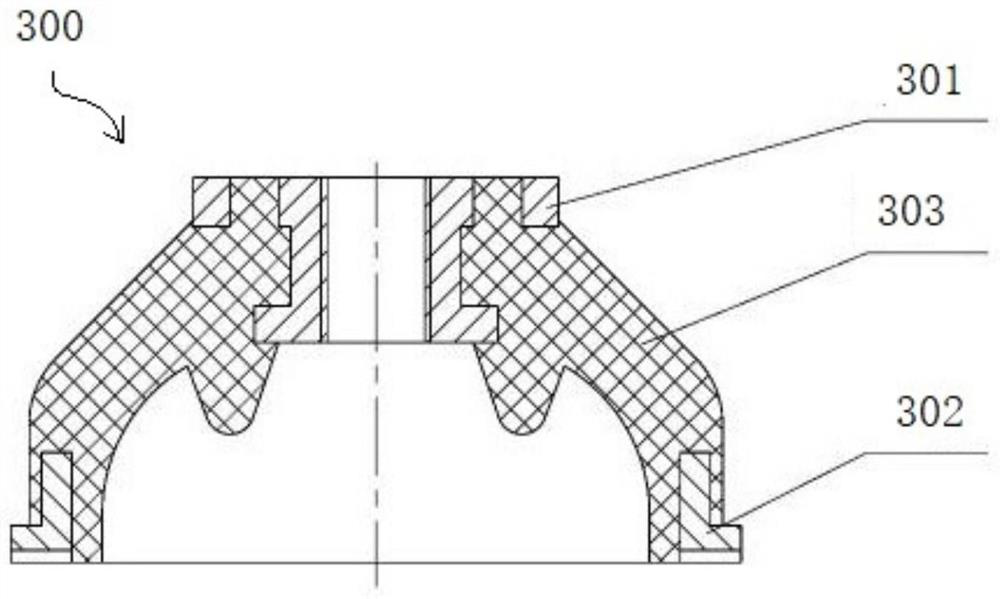

[0087] A radome weighs 10kg. Before leaving the factory, a 1g sine sweep test is performed to find out the resonance point, and then a 2g fixed-point sine vibration is applied to the resonance point. Due to the large amplification, cracks appear on the radome FRP panel. The magnification factor measured on site is as high as More than 30 times. After failure analysis, it was decided to adopt the three-way shear damper 100 of the present application. According to the installation space requirements, the outer diameter D1 of the metal inner cylinder 1 is determined to be 10 mm, so that the first buffer member 4 has an inner diameter D2 = 10 mm, an outer diameter D3 = 16 mm, a thickness t1 = 3 mm, and a height H1 = 15 mm. The inner diameter D4 of the second buffer member 5 = 16 mm, the outer diameter D5 = 32 mm, and the thickness t2 = 3 mm. Other relevant dimensions are determined according to actual conditions. The first buffer member 4 and the second buffer member 5 are made o...

Embodiment 2

[0089]An electronic device weighs 3kg and needs to withstand a sine sweep vibration test of 5g and a random vibration test of 13.5g. It requires equal frequencies in three directions, and the magnification of the resonance point is less than 3 times. The traditional metal-rubber composite structure shock absorber can never meet the requirements. requirements, after analysis, it is decided to adopt the application scheme for it. According to the installation space requirements, the outer diameter D1 of the metal inner cylinder 1 is determined to be 12 mm, so that the first buffer member 4 has an inner diameter D2 = 12 mm, an outer diameter D3 = 18 mm, t1 = 3 mm, and a height H1 = 18 mm. The inner diameter D4 of the second buffer member 5 = 19 mm, the outer diameter D5 = 39 mm, and the thickness t2 = 3.5 mm. Other relevant dimensions are determined according to actual conditions. The first buffer member 4 is made of high-damping silicon rubber material with a dynamic elastic mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com