Filling and curing slurry for horizontal directional drilling and preparation method thereof

A horizontal directional drilling and mud technology, applied in the field of filling mud, can solve the problems of low solid phase content, collapse of important water channels or roads, etc., and achieve the effects of long initial setting time, avoiding collapse accidents and small shrinkage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

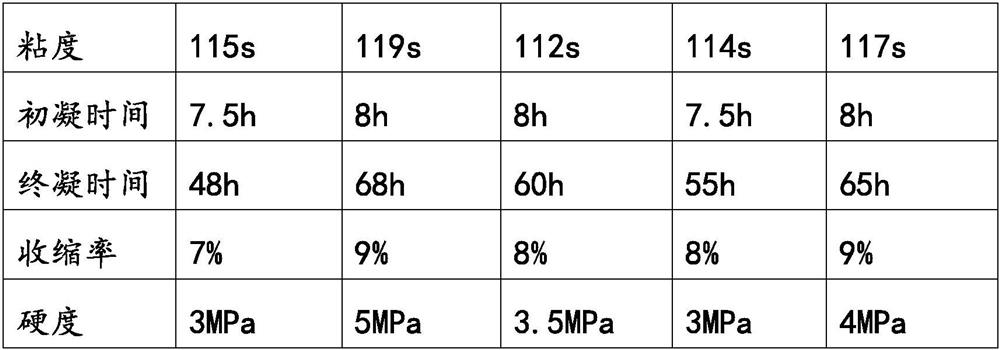

Examples

Embodiment 1

[0033] This embodiment provides a filling and solidifying mud for horizontal directional drilling, which consists of the following components by weight: water: 20 parts; bentonite: 11.3 parts; cement: 6.5 parts; silt: 55 parts; nonionic cellulose: 3 parts; polypolymer of vinyl monomers: 0.05 parts; ethylenediammonium tetramethylenephosphonic acid: 0.04 parts and sodium polyacrylate: 0.04 parts.

[0034] This embodiment provides a preparation method for filling and solidifying mud for horizontal directional drilling, comprising the following steps:

[0035] S1, raw materials are taken according to the following parts by weight: water: 20 parts; bentonite: 11.3 parts; cement: 6.5 parts; silt: 55 parts; nonionic cellulose: 3 parts; vinyl monomer multiple copolymer: 0.05 parts; Ethylenediammonium tetramethylenephosphonic acid: 0.04 part and sodium polyacrylate: 0.04 part.

[0036] S2. Stir and mix the nonionic cellulose, the vinyl monomer multi-polymer, the corrosion inhibitor an...

Embodiment 2

[0041] This embodiment provides a filling and solidifying mud for horizontal directional drilling, which consists of the following components in parts by weight: water: 20 parts; bentonite: 13.3 parts; cement: 8.5 parts; silt: 61 parts; nonionic fiber Sodium ethylenediammonium tetramethylene phosphonate: 0.06 parts and sodium polyacrylate: 0.06 parts.

[0042] This embodiment provides a preparation method for filling and solidifying mud for horizontal directional drilling, comprising the following steps:

[0043] S1, raw materials are taken according to the following parts by weight: water: 20 parts; bentonite: 13.3 parts; cement: 8.5 parts; silt: 61 parts; nonionic cellulose: 5 parts; vinyl monomer multiple copolymer: 0.15 parts; Sodium ethylene diammonium tetramethylene phosphonate: 0.06 part and sodium polyacrylate: 0.06 part.

[0044] S2. Stir and mix the nonionic cellulose, the vinyl monomer polypolymer, the corrosion inhibitor and the sodium polyacrylate weighed in step...

Embodiment 3

[0049] This embodiment provides a filling and solidifying mud for horizontal directional drilling, which consists of the following components in parts by weight: water: 20 parts; bentonite: 12.3 parts; cement: 7.5 parts; silt: 58 parts; nonionic fiber Sodium ethylenediammonium tetramethylene phosphonate: 0.05 parts and sodium polyacrylate: 0.05 parts.

[0050] This embodiment provides a preparation method for filling and solidifying mud for horizontal directional drilling, comprising the following steps:

[0051] S1, raw materials are taken according to the following parts by weight: water: 20 parts; bentonite: 12.3 parts; cement: 7.5 parts; silt: 58 parts; nonionic cellulose: 4 parts; vinyl monomer multiple copolymer: 0.01 part; Sodium ethylene diammonium tetramethylene phosphonate: 0.05 part and sodium polyacrylate: 0.05 part.

[0052] S2. Stir and mix the nonionic cellulose, the vinyl monomer polypolymer, the corrosion inhibitor and the sodium polyacrylate weighed in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com