Water reducing agent for high-strength concrete and preparation method thereof

A high-strength concrete and water-reducing agent technology, which is applied in the field of concrete admixtures, can solve problems such as high viscosity of concrete, poor volume stability, and complex manufacturing process, and achieve good corrosion resistance, good compatibility, and less dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

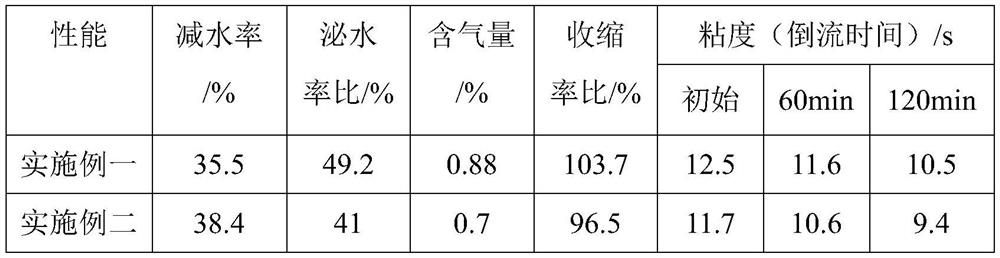

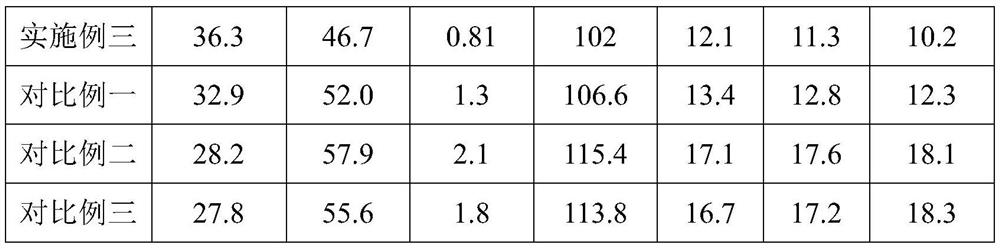

Examples

Embodiment 1

[0023] A water-reducing agent for high-strength concrete proposed by the present invention includes the following raw materials in parts by weight: 20 parts of acrylic acid, 2 parts of chain transfer agent, 1 part of ammonium persulfate, 20 parts of methoxypolyethylene glycol, polyethylene glycol 15 parts of ether, 1 part of 1,3-dimethylimidazole methyl sulfate, 2 parts of sucrose fatty acid ester, 8 parts of carbon fiber powder, 2 parts of defoamer, 10 parts of sodium hydroxide;

[0024] Wherein, the mass ratio of 1,3-dimethylimidazole methyl sulfate to sucrose fatty acid ester is 1:2;

[0025] Among them, the chain transfer agent is prepared from 2,3-dimethylbutadiene, glycosaminoglycan, tetrahydrofuran, cyclohexane, ethanol and citric acid with a mass ratio of 1:2.5:1:1:4:1.2 ; The preparation method is: according to the mass ratio, mix tetrahydrofuran and cyclohexane to obtain a mixed solution, add 2,3-dimethylbutadiene and glycosaminoglycans to the mixed solution in turn ...

Embodiment 2

[0032] A water-reducing agent for high-strength concrete proposed by the present invention comprises the following raw materials in parts by weight: 30 parts of acrylic acid, 3.5 parts of chain transfer agent, 2 parts of ammonium persulfate, 25 parts of methoxypolyethylene glycol, polyethylene glycol 20 parts of ether, 1.5 parts of 1,3-dimethylimidazole methyl sulfate, 4.5 parts of sucrose fatty acid ester, 12 parts of carbon fiber powder, 3.5 parts of defoamer, 14 parts of sodium hydroxide;

[0033] Wherein, the mass ratio of 1,3-dimethylimidazole methyl sulfate to sucrose fatty acid ester is 1:3;

[0034]Among them, the chain transfer agent is prepared from 2,3-dimethylbutadiene, glycosaminoglycan, tetrahydrofuran, cyclohexane, ethanol and citric acid with a mass ratio of 1:4:2:3:6:1.6 ; The preparation method is: according to the mass ratio, mix tetrahydrofuran and cyclohexane to obtain a mixed solution, add 2,3-dimethylbutadiene and glycosaminoglycans to the mixed solution...

Embodiment 3

[0041] A water-reducing agent for high-strength concrete proposed by the present invention comprises the following raw materials in parts by weight: 40 parts of acrylic acid, 5 parts of chain transfer agent, 3 parts of ammonium persulfate, 30 parts of methoxypolyethylene glycol, polyethylene glycol 25 parts of ether, 2 parts of 1,3-dimethylimidazole methyl sulfate, 8 parts of sucrose fatty acid ester, 15 parts of carbon fiber powder, 5 parts of defoamer, 18 parts of sodium hydroxide;

[0042] Wherein, the mass ratio of 1,3-dimethylimidazole methyl sulfate to sucrose fatty acid ester is 1:4;

[0043] Among them, the chain transfer agent is prepared from 2,3-dimethylbutadiene, glycosaminoglycan, tetrahydrofuran, cyclohexane, ethanol and citric acid with a mass ratio of 1:5:3:5:8:2 ; The preparation method is: according to the mass ratio, mix tetrahydrofuran and cyclohexane to obtain a mixed solution, add 2,3-dimethylbutadiene and glycosaminoglycans to the mixed solution in turn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com