Fluoride/oxyfluoride fluorescent glass ceramic, preparation method and application thereof

A technology of oxyfluoride and fluorescent glass, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems that the rare earth ion active luminescent center cannot be firm, it is difficult to meet the needs of practical applications, and the fluorescence emission intensity is reduced. Avoiding non-radiative transitions, high photoconversion efficiency and luminous performance, and short holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] La(NO 3 ) 3 ·6H 2 O and Eu(NO 3 ) 3 ·XH 2 O was accurately weighed at a molar ratio of (La:Eu=95:5), dissolved in deionized water at room temperature, placed in an oil bath at 65°C with magnetic stirring, and the stirring rate was set at 500rpm; excess NH 4 F dissolved in a small amount of deionized water, the NH 4 Solution F is slowly dripped into the above mixed solution, and a white precipitate can be observed, then add nitric acid or hydrochloric acid solution to adjust the pH value to 2-3, continue stirring and heating for 90 minutes; further perform hydrothermal treatment on the mixed solution, and mix the precipitated Move the solution into a 100ml hydrothermal kettle and react at 180°C for 18 hours. After the reaction, take out the hydrothermal kettle and cool it to room temperature naturally, pour off the supernatant, and wash the precipitate with deionized water and absolute ethanol respectively. , centrifuged three times, and the obtained white precipit...

Embodiment 2

[0026] Y(NO 3 ) 3 ·6H 2 O and Eu(NO 3 ) 3 ·XH 2 O was accurately weighed at a molar ratio of (Y:Eu=95:5), dissolved in deionized water at room temperature, placed in an oil bath at 65°C with magnetic stirring, and the stirring rate was set at 500rpm; excess NH 4 F dissolved in a small amount of deionized water, the NH 4 The F solution is slowly dropped into the above mixed solution, and a white precipitate can be observed, then a certain amount of nitric acid or hydrochloric acid solution is added to adjust the pH value to 2-3, and the stirring and heating are continued for 90 minutes; the mixed solution is further hydrothermally treated, and the The precipitated mixed solution was transferred to a 100ml hydrothermal kettle, and reacted at 180°C for 18 hours. After the reaction, the hydrothermal kettle was taken out and cooled to room temperature naturally, and the supernatant was poured out, and deionized water and absolute ethanol were used to The precipitate was washe...

Embodiment 3

[0029] The dried YF after centrifugation of embodiment 2 3 :Eu 3+ The nanocrystals are fully ground in a mortar, and then the powder is put into a muffle furnace and heated to 300°C, 400°C, 500°C, 600°C, 700°C, 800°C, and 900°C at a heating rate of 2°C / min. , after three hours of heat preservation, it was naturally cooled to room temperature to obtain YOF:Eu 3+ Nanocrystalline.

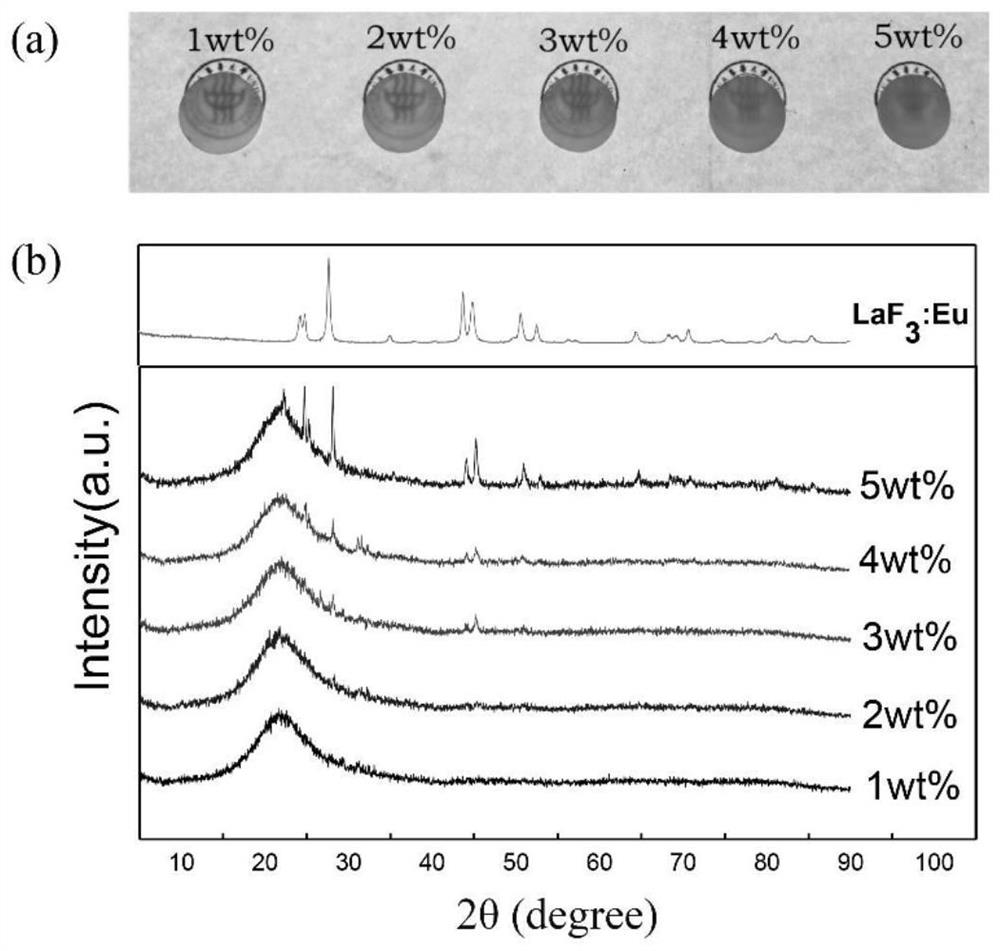

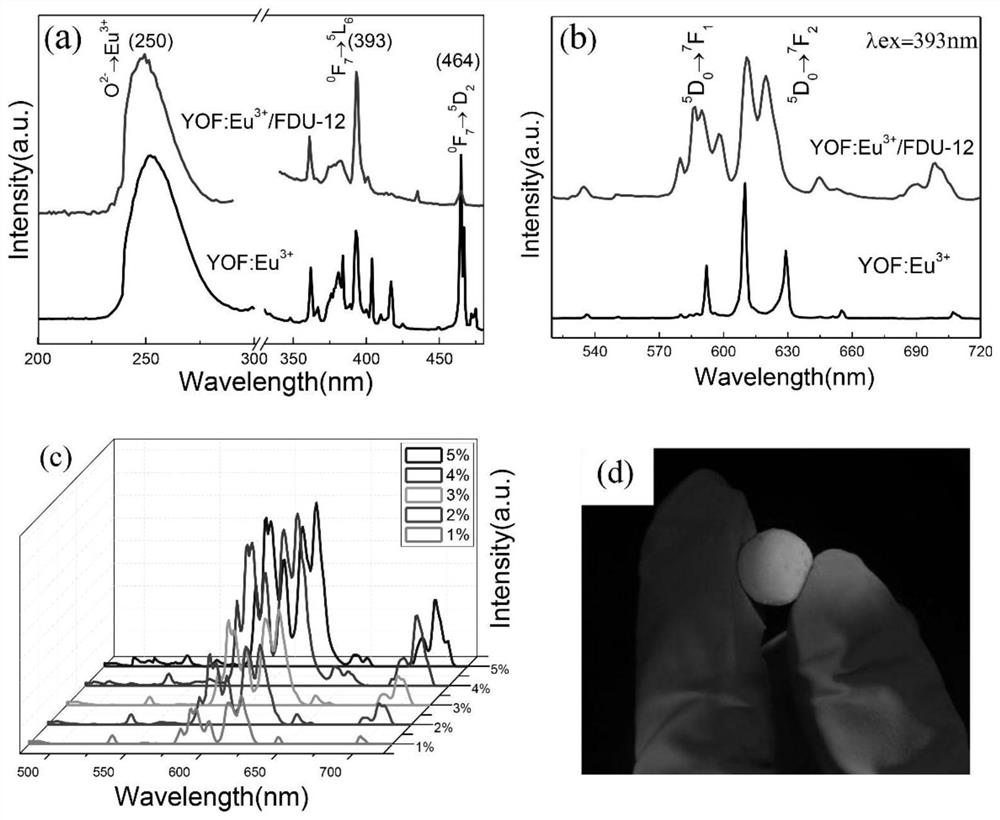

[0030] Using MCM-41 mesoporous silicon-based powder and YOF:Eu 3+ The luminous nano crystal powder is used as the starting material. Raw materials were mixed in different weight ratios (YOF:Eu 3+ Luminescent nanocrystalline powder: 1wt%, 2wt%, 3wt%, 4wt%, 5wt%) are uniformly ground and mixed, and then moved into a graphite mold with an inner diameter of 10mm. By spark plasma sintering, the mixed powder was sintered under a uniaxial pressure of 100 MPa for about 10 min according to specific sintering parameters. The detailed sintering parameters are as follows: After heating at 600 °C for 3 min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com