A kind of hydroxyapatite-based fluorescent ceramic material and its preparation method

A technology based on hydroxyapatite and hydroxyapatite, which is applied in the field of fluorescent materials, can solve the problems of complex, high temperature of transparent ceramics, strict requirements on raw material ratio, etc., achieve simple preparation process, reduce sintering temperature and time, and purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

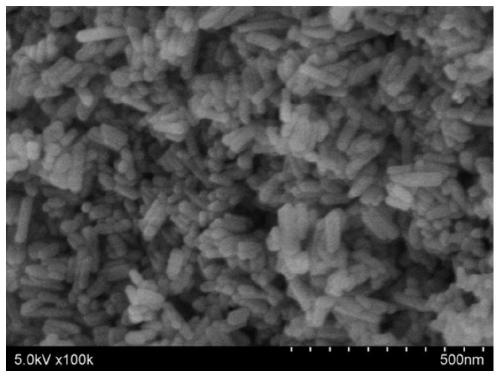

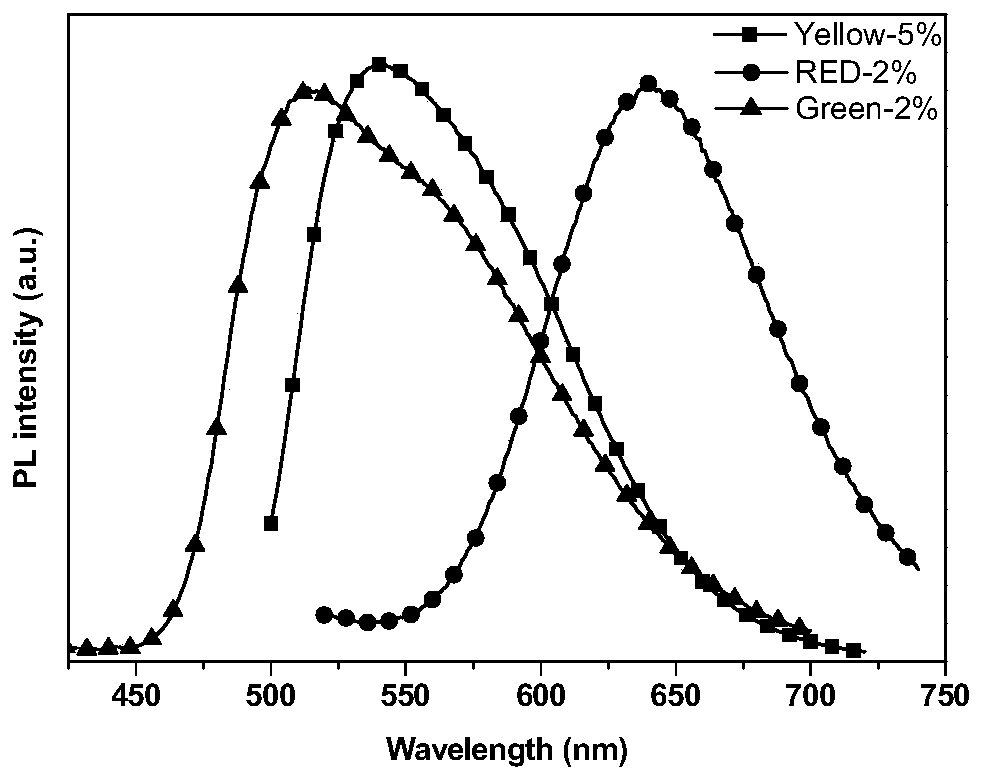

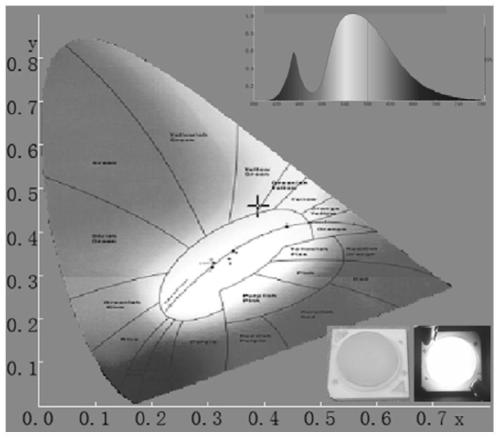

[0029] Using calcium nitrate and diammonium hydrogen phosphate as raw materials, the concentration of calcium nitrate is 0.9mol / L to prepare solution A, and the concentration of diammonium hydrogen phosphate is 1.8mol / L to prepare solution B; under the ice bath environment, the solution A is prepared according to the ion molar ratio to Ca : P=1.6:1, drop speed 3ml / min, slowly drop into B solution, adjust reaction environment pH>10 with ammonia water during the reaction; react 2h after dropping, obtain C suspension, turn C solution into high pressure Carry out hydrothermal in the reaction kettle, the hydrothermal reaction temperature is 130°C, and the hydrothermal reaction time is 24h; after hydrothermal filtration, the precipitate is washed with water and alcohol to obtain the precursor of hydroxyapatite powder, which is fully dried in an oven; The powder was calcined in a muffle furnace at a calcining temperature of 250° C., a heating rate of 5° C. / min, and a holding time of 2...

Embodiment 2

[0032]Using calcium nitrate and diammonium hydrogen phosphate as raw materials, the concentration of calcium nitrate is 0.3mol / L to prepare solution A, and the concentration of diammonium hydrogen phosphate to prepare solution B; : P=1.5:1, dripping speed 1ml / min, slowly drop into B solution, adjust the reaction environment pH>10 with ammonia water during the reaction; react for 2h after the drop is completed, obtain C suspension, turn C solution into high pressure Carry out hydrothermal in the reaction kettle, the hydrothermal reaction temperature is 100°C, and the hydrothermal reaction time is 12h; after hydrothermal filtration, the precipitate is washed with water and alcohol to obtain the precursor of hydroxyapatite powder, which is fully dried in an oven; The powder was calcined in a muffle furnace at a calcining temperature of 700° C., a heating rate of 5° C. / min, and a holding time of 2 hours to obtain a hydroxyapatite matrix.

[0033] Grind and mix the commercial red p...

Embodiment 3

[0035] Using calcium nitrate and diammonium hydrogen phosphate as raw materials, the concentration of calcium nitrate is 0.9mol / L to prepare solution A, and the concentration of diammonium hydrogen phosphate is 1.8mol / L to prepare solution B; under the ice bath environment, the solution A is prepared according to the ion molar ratio to Ca : P=2:1, drop speed 2ml / min, slowly drop into solution B, adjust the reaction environment pH>10 with ammonia water during the reaction; react for 2 hours after the addition is completed, obtain C suspension, transfer C solution to high pressure Carry out hydrothermal in the reaction kettle, the hydrothermal reaction temperature is 130°C, and the hydrothermal reaction time is 24h; after hydrothermal filtration, the precipitate is washed with water and alcohol to obtain the precursor of hydroxyapatite powder, which is fully dried in an oven; The powder was calcined in a muffle furnace at a calcining temperature of 250° C., a heating rate of 5° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| luminous efficiency | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com