Gamma-alumina nanofiber and preparation method thereof

A technology of alumina nanometer and aluminum hydroxide, which is applied in the preparation of alumina/hydroxide, alkali metal aluminate/alumina/aluminum hydroxide preparation, chemical instruments and methods, etc., can solve the problem of γ-alumina nanometer Small fiber pore volume, non-uniform supersaturation, low mixing efficiency, etc., to achieve the effect of improving uniformity of supersaturation, low cost, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

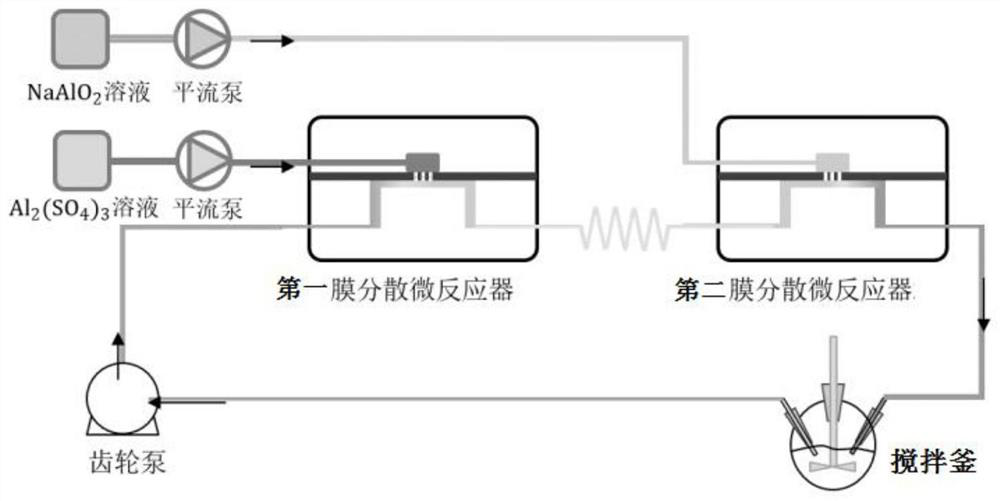

[0030] The invention provides a method for preparing gamma-alumina nanofibers, comprising the following steps:

[0031] Dispersing the first dispersed phase solution in the mobile phase through the first membrane dispersion microreactor to obtain the dispersed phase solution;

[0032] Using the dispersed phase solution as the mobile phase, the second dispersed phase solution is dispersed in the dispersed phase solution through the second membrane dispersion microreactor, and a precipitation reaction is carried out to obtain an aluminum hydroxide suspension;

[0033] The aluminum hydroxide suspension is used as the mobile phase, and the dispersion process of the first dispersed phase solution and the second dispersed phase solution is circulated in sequence until the volume of the mobile phase increases to 3 to 5 times the initial value to obtain hydrogen Alumina precursor;

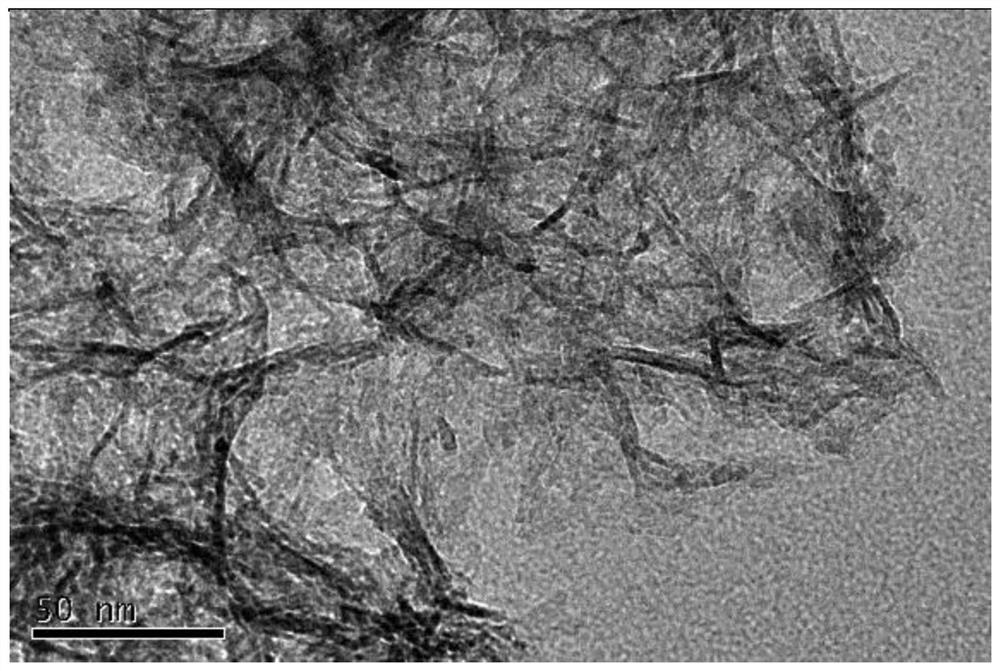

[0034] Aging and calcining the aluminum hydroxide precursor in sequence to obtain γ-alumina nanofibers...

Embodiment 1

[0056] Under the condition of 80°C, prepare an aqueous solution of aluminum sulfate with a molar concentration of 0.44mol / L and an aqueous solution of sodium metaaluminate with a molar concentration of 2.00mol / L. The flow rate is passed through the first membrane dispersion microreactor (the micropore diameter of the porous membrane used is 15 μm), and enters the mobile phase (300mL of pure water, flow rate is 244mL / min) of the communication pipeline to obtain the dispersed phase solution;

[0057] Using the dispersed phase solution as the mobile phase (the flow rate is 259mL / min), the sodium metaaluminate aqueous solution is passed through the second membrane dispersion microreactor (the pore diameter of the porous membrane used is 15 μm) with a flow rate of 21mL / min. In the phase, a precipitation reaction is carried out to obtain an aluminum hydroxide suspension (the temperature is 80° C., and the solid content is 5.2%);

[0058] With the aluminum hydroxide suspension as the...

Embodiment 2

[0065] Under the condition of 80°C, prepare an aqueous solution of aluminum sulfate with a molar concentration of 0.125 mol / L and an aqueous solution of sodium metaaluminate with a molar concentration of 0.50 mol / L. The flow rate is passed through the first membrane dispersion microreactor (the micropore diameter of the porous membrane used is 15 μm), and enters the mobile phase (pure water, volume is 300mL, and flow rate is 189mL / min) in the communication pipeline to obtain the dispersed phase solution;

[0066] With the dispersed phase solution as the mobile phase (the flow rate is 219mL / min), the sodium metaaluminate aqueous solution is passed through the second membrane dispersion microreactor (the pore diameter of the porous membrane used is 15 μm) with a flow rate of 26mL / min. In the phase, a precipitation reaction is carried out to obtain an aluminum hydroxide suspension (the temperature is 80° C., and the solid content is 1.4%);

[0067] With the aluminum hydroxide sus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com