Construction method of 3D micro/nano structure

A nanostructure and 3D technology, applied in the field of 3D micro/nanostructure construction, can solve problems such as complex structure reverse replication process, and achieve the effect of good application and promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for constructing a 3D micro / nano structure, comprising the following steps:

[0027] (1) Take a silicon wafer with a length and width of 1 cm and use ultrapure water, ethanol, and acetone for 10 minutes of ultrasonication as the substrate 2, and deposit a layer of ZnO film with a thickness of 100 nm on the silicon substrate by magnetron sputtering coating method , with this ZnO thin film as the material source for building a three-dimensional structure 3, put the silicon substrate on which the ZnO thin film is deposited into the vacuum chamber of the electron microscope to evacuate, so that the vacuum degree reaches 10 - 4 Pa;

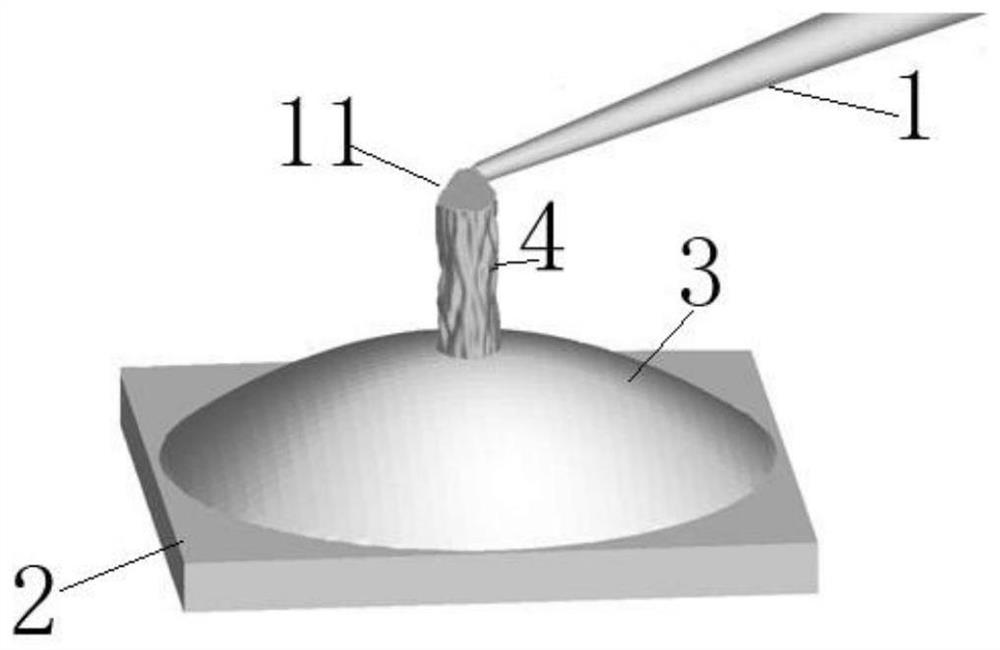

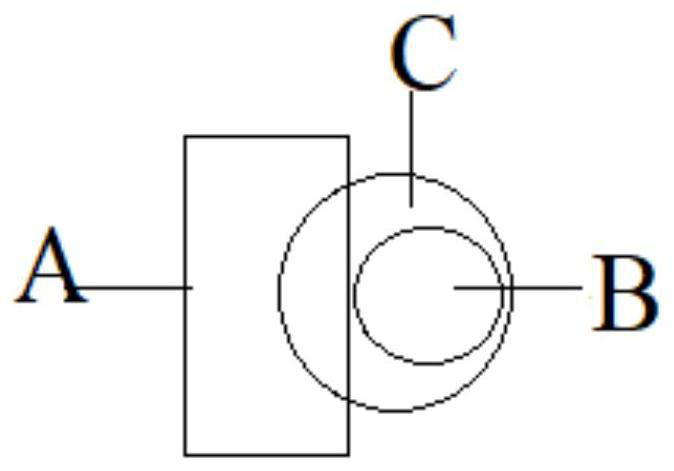

[0028] (2) Turn on the filament, adjust the state of the electron beam 1 and the grating displacement platform, the working distance is 7mm, the accelerating voltage is 10kV, the electron beam spot is 10nm, and the electron beam 1 is obliquely incident on the ZnO surface at an angle of 70° (such as figure 1 shown), the electron beam f...

Embodiment 2

[0031] A method for constructing a 3D micro / nano structure, comprising the following steps:

[0032] (1) Synthesize cobalt-nickel hydroxide polycrystalline nanowires by hydrothermal method, then anneal at 400 degrees Celsius for 2 hours in a muffle furnace to form cobalt-nickel oxide polycrystalline nanowire powders, and disperse cobalt-nickel oxide polycrystalline nanowires into On the silicon wafer substrate, as the source material for growing nano-germ, put the above-mentioned silicon wafer substrate into the vacuum chamber of the electron microscope to evacuate, so that the vacuum degree reaches 10 -3 Pa;

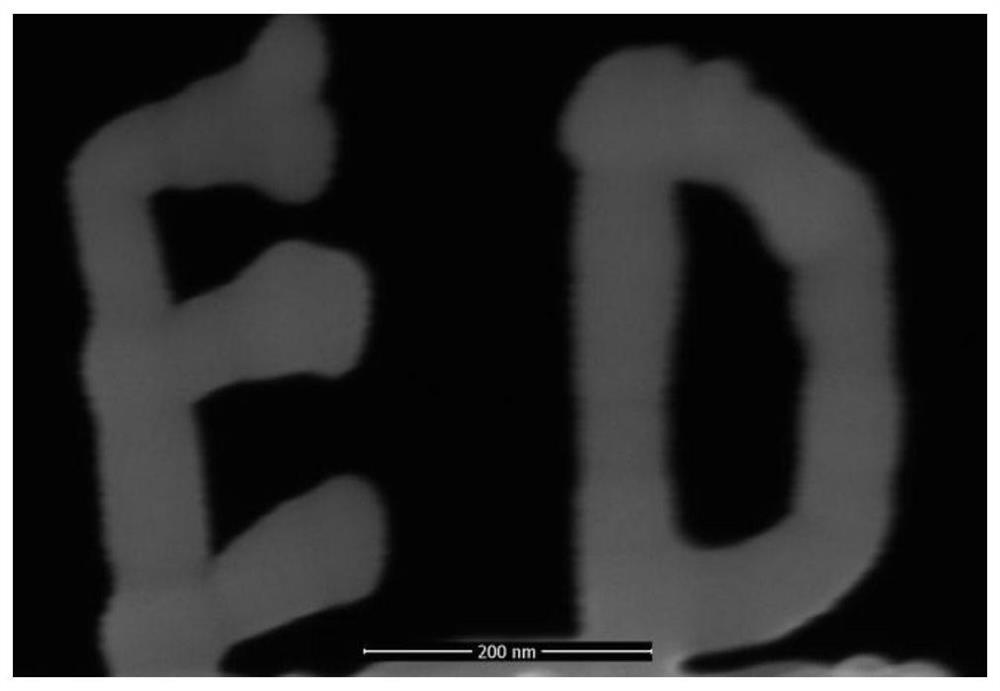

[0033] (2) Turn on the filament, adjust the state of the electron beam and the grating displacement platform, the working distance is 12mm, the accelerating voltage is 15kV, the electron beam spot is 20nm, and the electron beam is focused so that the focus of the electron beam is located at the growth point of the cobalt-nickel oxide polycrystalline nanowire powder The...

Embodiment 3

[0036] A method for constructing a 3D micro / nano structure, comprising the following steps:

[0037] (1) Take a copper sample stage as the substrate, take a section of copper wire, pull it off forcefully, fix it on the copper sample stage with conductive tape, use the broken end of the copper wire as the growth point of the nanorod, and place the copper sample stage above Put it into the electron microscope vacuum chamber to evacuate to make the vacuum degree reach 10 -5 Pa;

[0038](2) Turn on the filament, adjust the state of the electron beam and the grating displacement platform, the working distance is 20mm, the accelerating voltage is 30kV, the beam spot of the electron beam is 50nm, and the electron beam is focused so that the focus of the electron beam is located in the vicinity of the copper wire growth point, and the copper wire grows The distance between the points is 50nm, and the surface layer near the electron beam focus and the copper wire growth point forms a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com