Pulsed power source for medium-speed WEDM smoothness machining and machining method of pulsed power source

A pulse power supply and clean technology, applied in metal processing equipment, electric processing equipment, circuits, etc., can solve the problems that the surface roughness of the workpiece cannot be further improved, the surface finish is not good, and the energy of the third knife repairing tool is too large, etc. , to achieve the effect of accelerating the deionization process, fast charging speed, and accelerating the current drop speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The scheme of the present invention will be further described below in conjunction with the accompanying drawings.

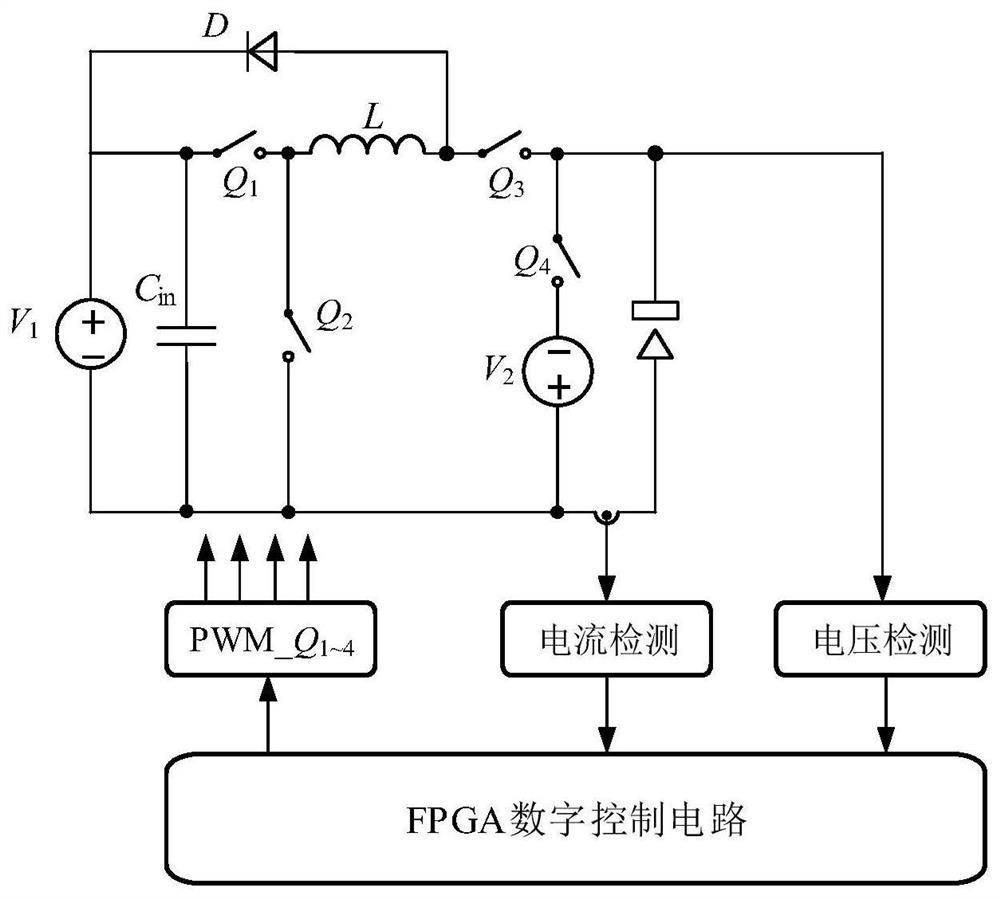

[0029] Such as figure 1 As shown, the pulse power supply for medium wire cutting clean processing includes a main power circuit, a voltage detection circuit, a current detection circuit, and an FPGA digital control circuit, wherein the main power circuit is used to charge the gap and provide discharge energy for tertiary processing; The current detection circuit and the voltage detection circuit are used to detect the current and voltage signal of the gap in the three-knife machining process in real time; the FPGA digital control circuit is used to generate a PWM signal according to the real-time gap voltage and current signal to control the conduction of the switching tube in the main power circuit. on and off.

[0030] The main power loop of the pulse power supply includes an input DC source (V 1 ), the first switching tube (Q 1 ), the second switchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com