Structured packing, packing layer structure and application thereof

A technology of structured packing and layer structure, which is applied in the field of rectification, can solve the problems of not installing anti-wall flow ring, wall flow surface tension material separation effect, etc., and achieve the effect of eliminating gap flow, improving the effect of anti-wall flow, and long residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In this example, deionized water is used as raw material to separate heavy water. This system has a relatively large surface tension and can generally represent the separation of water-containing mixtures. The separation uses a rectification tower with an inner diameter of 100 mm.

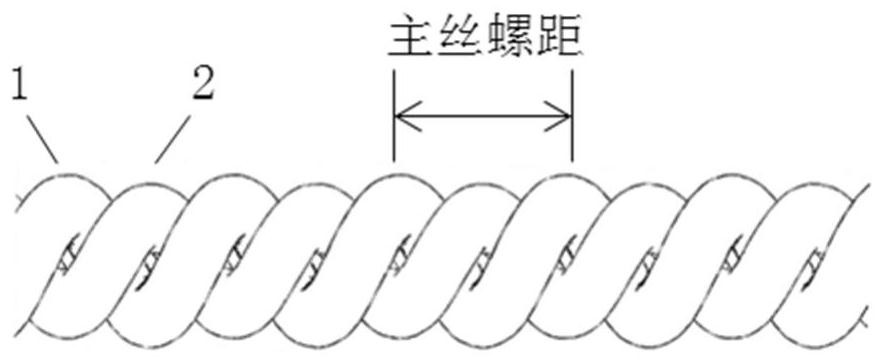

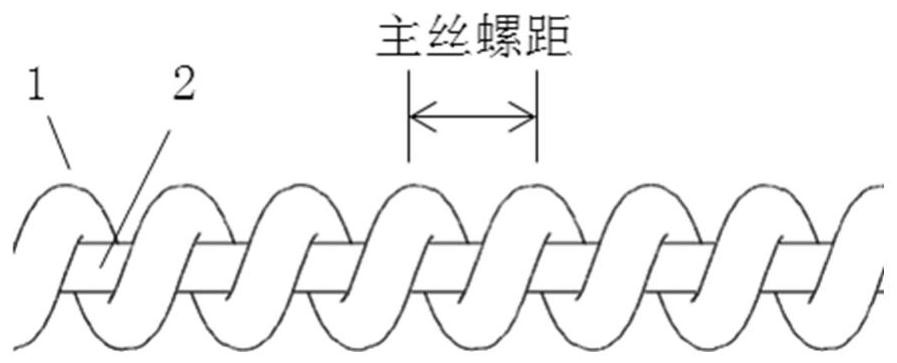

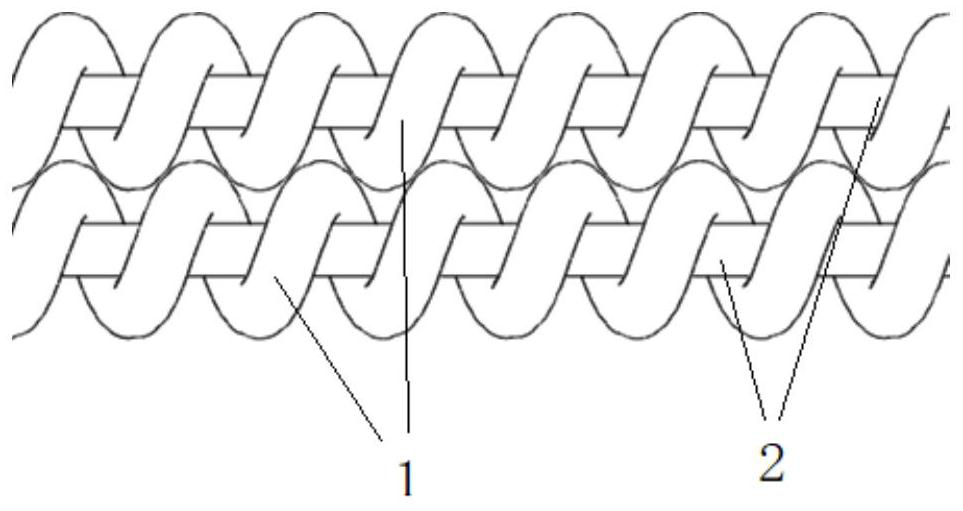

[0050] The materials of the main wire and the auxiliary wire of the winding silk thread are respectively 304 stainless steel and copper, the wire diameters of the main wire 1 and the auxiliary wire 2 are 0.22 mm and 0.04 mm respectively, and the winding method of the main wire 1 winding the auxiliary wire 2 is adopted (see figure 2 ), the pitch of the main wire 1 is 0.28mm, the screen weaving method adopts twill weaving, reverse arrangement (see Figure 4 ). The wire mesh strips are made by cutting the above-mentioned wire mesh, the weaving mesh number of the area with a width of 10 mm on both sides of the horizontal direction is 100 mesh, the weaving mesh number of the middle part of the c...

Embodiment 2

[0055] In this embodiment, a mixture of chlorotrifluoroethylene and chlorodifluoroethane is used as a raw material to separate chlorotrifluoroethylene. This system has a low viscosity and can generally represent the separation of halogenated hydrocarbons, especially the separation of chlorofluorocarbons with carbon 5 and below. The separation adopts a rectification tower with an inner diameter of 300 mm.

[0056] The main wire 1 and auxiliary wire 2 of the winding wire are made of phosphor bronze and 316L stainless steel respectively. The wire diameters of the main wire 1 and the auxiliary wire 2 are 0.35mm and 0.03mm respectively, and the winding method of the main wire 1 and the auxiliary wire 2 is adopted ( see figure 1 ), the pitch of the main wire 1 is 0.78mm, the wire mesh weaving method adopts twill weaving, and the arrangement is cis (see image 3 ). The wire mesh strips are made by cutting the above-mentioned wire mesh, the mesh number of the 50 mm wide area on both...

Embodiment 3

[0061] In this example, a mixture of n-heptane and methylcyclohexane is used as a raw material to separate n-heptane as an example. The surface tension and viscosity of this system are moderate, which can generally represent the separation of general organic matter. Separation adopts a rectification column with an inner diameter of 500mm.

[0062] The main wire 1 and auxiliary wire 2 of the winding wire are made of 316L stainless steel. The wire diameters of the main wire 1 and the auxiliary wire 2 are both 0.3 mm. The main wire 1 is wound around the auxiliary wire 2. The pitch of the main wire 1 is 0.35 mm, the wire mesh weaving method adopts plain weave, arranged in parallel. The wire mesh strips are made by cutting the above wire mesh, and the mesh number of the 30 mm wide area on both sides of the horizontal direction is 70 mesh, and the mesh number of the middle part of the strip sheet is 60 mesh. A circular hole with a diameter of 2 mm is opened in the middle of the wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com