Microwave-responsive admixture active release capsule and preparation method thereof

An admixture and active technology, which is applied in the direction of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., can solve problems such as difficult release, and achieve the effect of active control, wide sources, and strong ability to load admixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

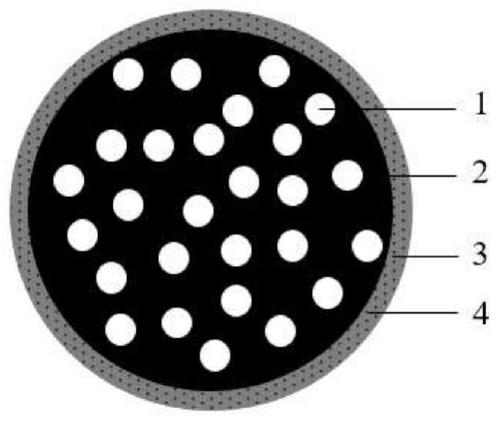

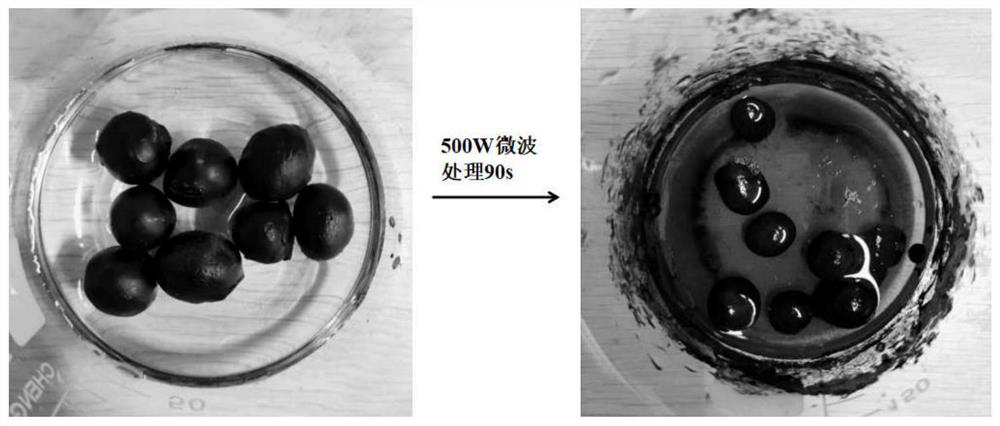

[0029] The porous ceramsite with a particle size of 1.0 cm was immersed in the polycarboxylate water reducer (20% by mass fraction), and vacuum treated for 24 hours, so that the porous ceramsite was fully loaded with the polycarboxylate water reducer. Heat paraffin wax (phase transition temperature 55-60°C) at 70°C to melt it, add 10% Fe 3 o 4 and stir slowly to make Fe 3 o 4 Distribute evenly in molten paraffin, quickly put the porous ceramsite loaded with polycarboxylate superplasticizer into the 3 o 4 In the molten paraffin, quickly roll several times, so that the surface of the porous ceramsite is evenly coated with a layer of paraffin, take it out, cool to room temperature, and obtain active release capsules.

[0030] The loading capacity of the active release capsule is defined as: the mass percentage of the loaded polycarboxylate superplasticizer to the total mass of the active release capsule. The active release capsules were found to have a loading capacity of 71...

Embodiment 2

[0032] Submerge the porous ceramsite with a particle size of 1.2cm in the carboxyamino alcohol rust inhibitor (yellow liquid, 30% mass fraction), and vacuum treatment for 24 hours, so that the porous ceramsite is fully loaded with the carboxy amino alcohol rust inhibitor. Heat paraffin wax (phase transition temperature 55-60°C) at 70°C to melt it, add 15% Fe3O4 and stir slowly to make Fe 3 o 4 Distribute evenly in molten paraffin, quickly put the porous ceramsite loaded with carboxyl amino alcohol rust inhibitor into the 3 o 4 In the molten paraffin, quickly roll several times, so that the surface of the porous ceramsite is evenly coated with a layer of paraffin, take it out, cool to room temperature, and obtain active release capsules.

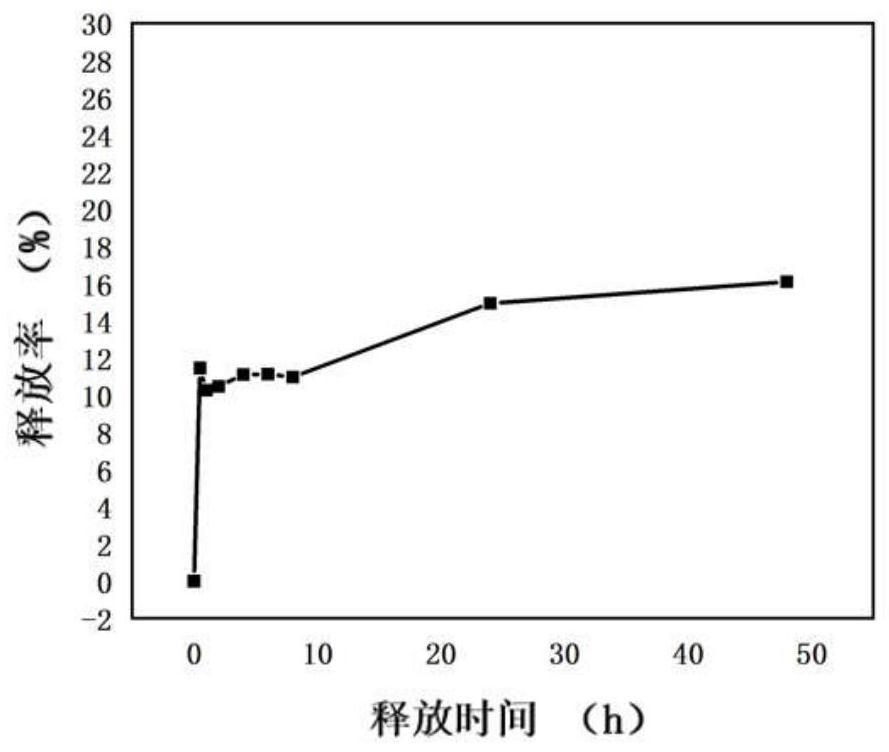

[0033] The active release capsules were placed in a concrete simulation solution that was saturated with Ca(OH) with 3.5% NaCl 2 solution, the volume ratio of the concrete simulated solution to the active release capsule is 4:1, the microw...

Embodiment 3

[0035] The porous ceramsite with a particle size of 1.1 cm was immersed in a polyethylene glycol tackifier (molecular weight: 1000, mass fraction: 20%), and vacuum treated for 24 hours, so that the porous ceramsite was fully loaded with the polyethylene glycol tackifier. Heat stearic acid at 70°C (phase transition temperature 55-60°C) to make it melt, add 25% Fe 3 o 4 and stir slowly to make Fe 3 o 4 Distribute evenly in molten stearic acid, quickly put the porous ceramsite loaded with polyethylene glycol viscosifier into the 3 o 4 In the melted stearic acid, quickly roll several times, so that the surface of the porous ceramsite is evenly coated with a layer of stearic acid, take it out, cool to room temperature, and obtain active release capsules.

[0036] Put the active release capsule into the concrete simulation solution, the concrete simulation solution is a saturated Ca(OH)2 solution with 3.5% NaCl, the volume ratio of the concrete simulation solution to the active ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com