PCB solder mask production process

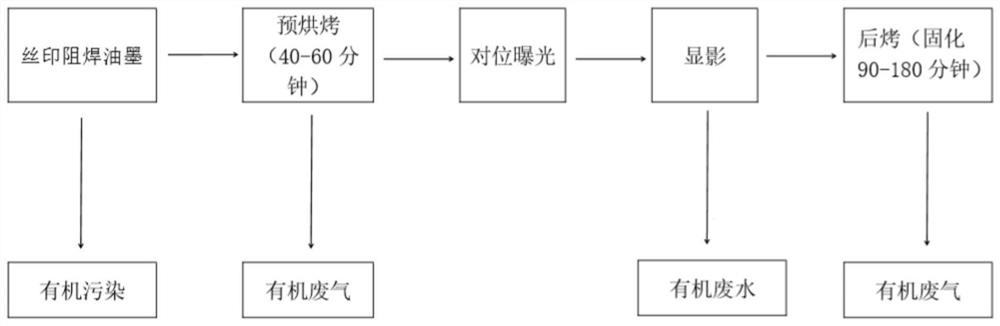

A production process and solder mask technology, applied in the secondary processing of printed circuits, electrical components, metallurgical bonding, etc., can solve the problems of low production efficiency, large water and electricity consumption, and high production costs, saving water, electricity, labor, and energy. Consumption and labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

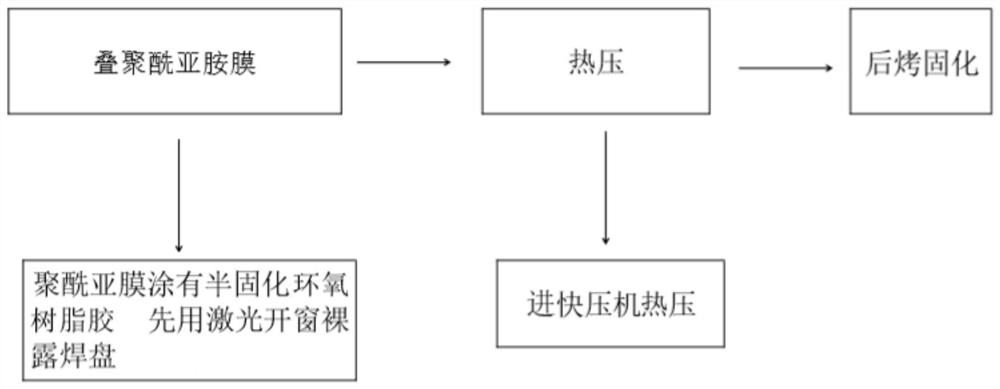

[0027] A PCB welding mask production process, comprising the following steps:

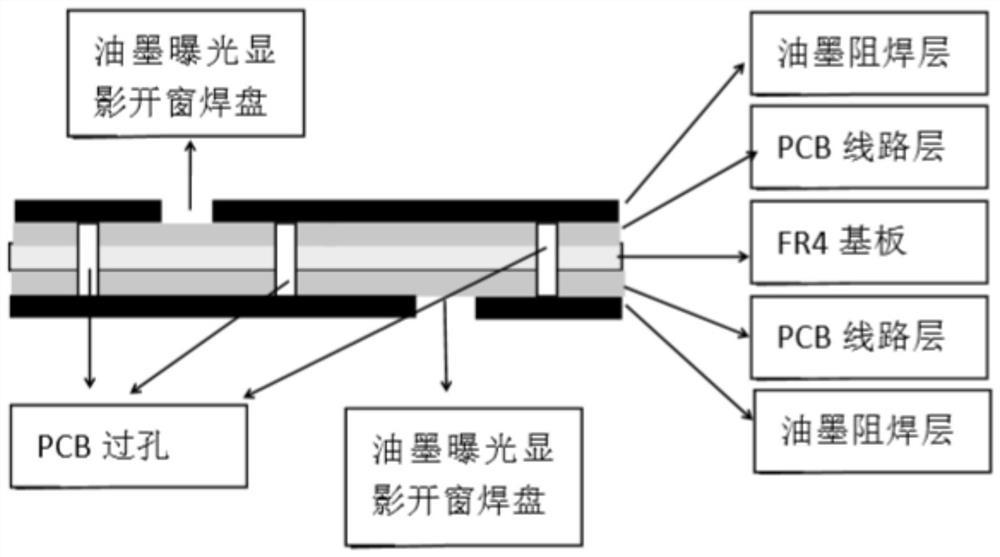

[0028] S1. Prepare raw materials, prepare a polyimide film coated with semi-cured epoxy resin glue or semi-solid acrylic on one side, prepare a PCB substrate that needs to be soldered, and combine the prepared polyimide film with the PCB Segmentation of the substrate into the size to be produced;

[0029] S2, the exposed pad, the polyimide film coated with semi-cured epoxy resin glue or coated with semi-cured acrylic in step S1 is windowed by laser to form a windowed pad on the surface, and multiple groups of polyimide The window pad size parameters of the amine film remain the same;

[0030] S3, stacking the films, stacking multiple groups of polyimide films with consistent window pads in step S2, and ensuring that the multiple groups of polyimide films are aligned consistently to form a laminated structure A;

[0031] S4, fixing the stacked film, and stacking the stacked structure A formed by s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com