A method for recycling and utilizing polyurethane film-forming controlled-release fertilizer resin residual film

A technology of controlled-release fertilizers and reaction film formation, which is applied in application, fertilizer mixtures, fertilization devices, etc., can solve the impact of nutrient release performance of unexplained coated controlled-release fertilizers, does not involve resin scarring reuse, does not give Problems such as the secondary utilization method of scarring and residual film have been solved to achieve the effect of reducing environmental pollution and reducing the cost of film materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for recycling polyurethane film-forming controlled-release fertilizer resin residual film, the steps are as follows:

[0038] (1) Recycling of Resin Residual Film Fine Powder

[0039] Collect the scars on the inner wall of the coating drum and the copying plate of the polyurethane reaction film-forming controlled-release urea production line, coarsely crush it through a 2mm sieve through a universal crusher, and then use the XQM-2L type produced by Nanjing Keyan Experimental Instrument Research Institute The ball mill uses water as the medium to carry out wet ball milling, stops after 6 hours, takes out the residual film, washes it with water 2-3 times, and puts it in an oven to dry, and finally becomes a uniform and loose fine powder of resin residual film. Measured by particle size analyzer, the average particle size is 28 μm.

[0040] (2) Utilization of resin residual film fine powder

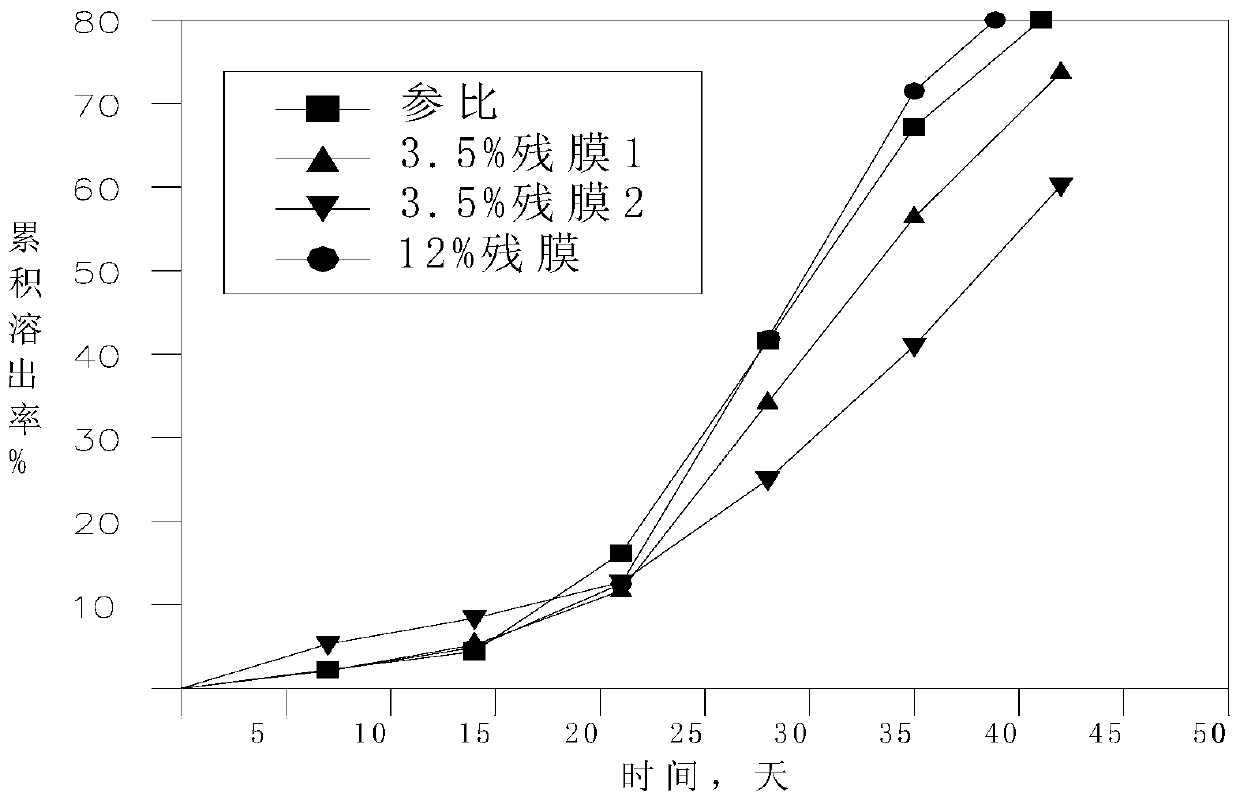

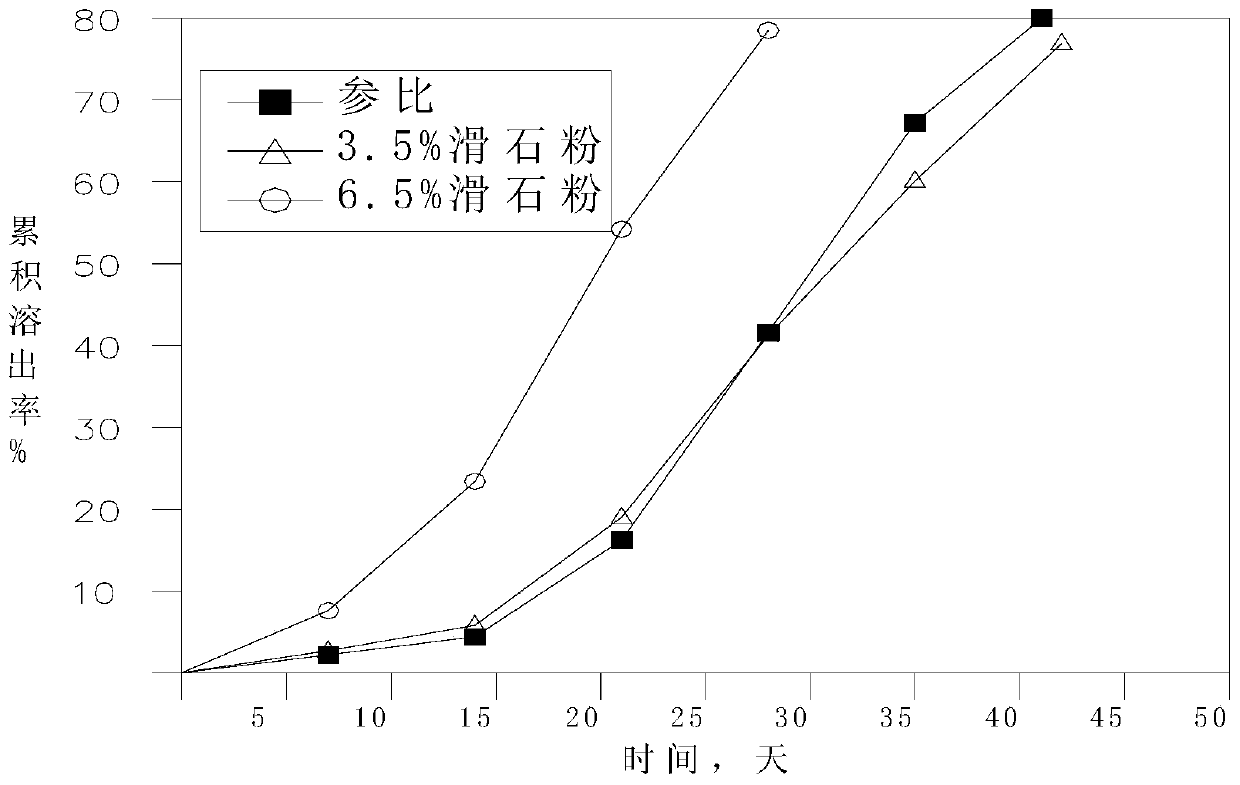

[0041] 3.5% by mass (3.5% refers to the ratio of residual film to the ...

Embodiment 2

[0049] A method for recycling polyurethane film-forming controlled-release fertilizer resin residual film, the steps are as follows:

[0050] (1) Recycling of Resin Residual Film Fine Powder

[0051] Collect the scars on the inner wall of the coating drum and the copying plate of the polyurethane reaction film-forming controlled-release urea production line, coarsely crush it through a 2mm sieve through a universal crusher, and then use the XQM-2L type produced by Nanjing Keyan Experimental Instrument Research Institute The ball mill uses water as the medium to carry out wet ball milling, stops after 6 hours, takes out the residual film, washes it with water 2-3 times, and puts it in an oven to dry, and finally becomes a uniform and loose fine powder of resin residual film. Measured by particle size analyzer, the average particle size is 28 μm.

[0052] (2) Utilization of resin residual film fine powder

[0053] 3.5% by mass resin residual film filler polyurethane coated ure...

Embodiment 3

[0059] A method for recycling polyurethane film-forming controlled-release fertilizer resin residual film, the steps are as follows:

[0060] (1) Recycling of Resin Residual Film Fine Powder

[0061] Collect the scars on the inner wall of the coating drum and the copying plate of the polyurethane reaction film-forming controlled-release urea production line, coarsely crush it through a 2mm sieve through a universal crusher, and then use the XQM-2L type produced by Nanjing Keyan Experimental Instrument Research Institute The ball mill uses water as the medium to carry out wet ball milling, stops after 6 hours, takes out the residual film, washes it with water 2-3 times, and puts it in an oven to dry, and finally becomes a uniform and loose fine powder of resin residual film. Measured by particle size analyzer, the average particle size is 28 μm.

[0062] (2) Utilization of resin residual film fine powder

[0063] 12% residual film filler polyurethane coated urea

[0064] Add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com