Indirect cooling type moving bed non-slag pure oxygen continuous gasification device and process

A gasification device and moving bed technology, applied in the field of coal gasification, can solve the problems of affecting the effect and efficiency of coal gas treatment, incomplete treatment efficiency of pollution treatment, and increasing wastewater discharge, so as to reduce the amount of residual carbon in ash residue and avoid secondary pollution. The effect of less pollution and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

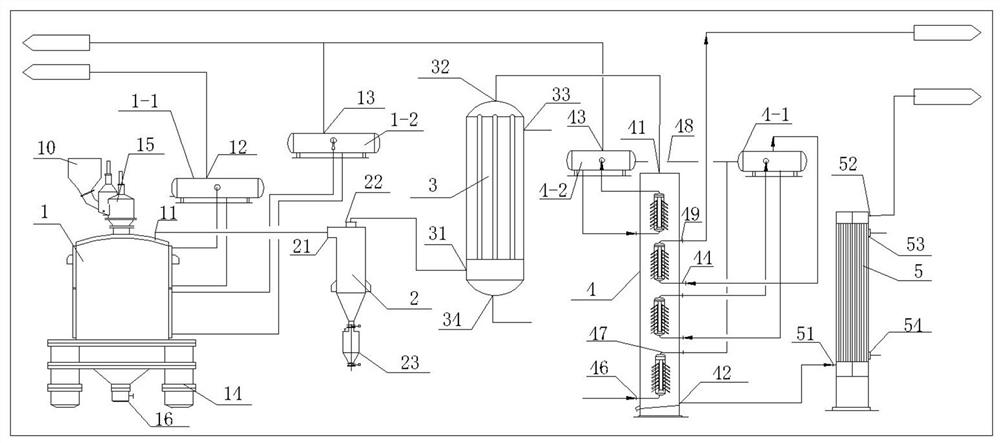

[0031] Such as figure 1 As shown, an intercooled moving bed non-slag pure oxygen continuous gasification device and process described in the present invention includes gasification equipment, dust removal equipment, waste heat recovery equipment and cold treatment equipment;

[0032] The gasification equipment includes a gasification furnace 1, the top of the gasification furnace 1 is provided with a raw coal hopper 10, the bottom of the gasification furnace 1 is provided with a gasification agent inlet 16, the gasification furnace 1 is provided with a gas outlet 11, and the gas outlet 11 passes through a connecting pipe Connect with dust removal equipment;

[0033] The dust removal equipment includes a cyclone dust collector 2 and a high-temperature bag filter 3, and the cyclone dust collector 2 and the high-temperature bag filter 3 operate in series, which can completely remove the dust entrained in the gas output from the gasifier 1, thereby It achieves the thorough purifi...

Embodiment 2

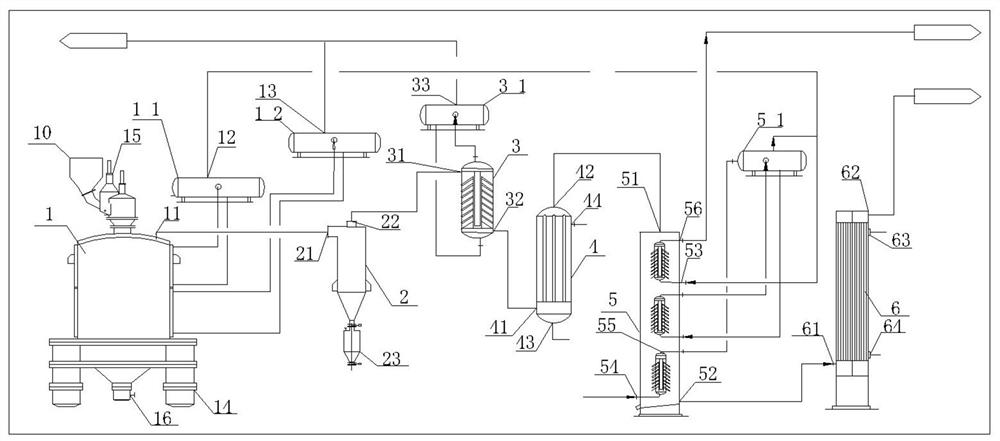

[0047] Such as figure 2 As shown, an intercooled moving bed non-slag pure oxygen continuous gasification device and process described in the present invention includes gasification equipment, dust removal equipment, waste heat recovery equipment and cold treatment equipment;

[0048] The gasification equipment includes a gasification furnace 1, the top of the gasification furnace 1 is provided with a raw coal hopper 10, the bottom of the gasification furnace 1 is provided with a gasification agent inlet 16, the gasification furnace 1 is provided with a gas outlet 11, and the gas outlet 11 passes through a connecting pipe Connect with dust removal equipment;

[0049] The dust removal equipment includes cyclone dust collector 2 and high temperature bag filter 4, between cyclone dust collector 2 and high temperature bag filter 4, there is a high temperature gas cooler 3, and the high temperature gas cooler 3 is respectively connected to the cyclone dust collector through connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com