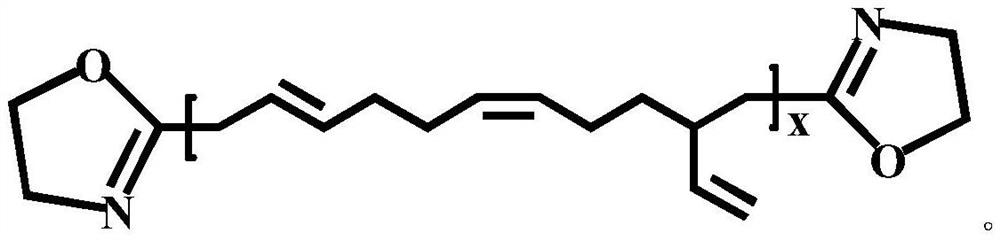

Oxazoline-terminated polybutadiene compound, and preparation method and application thereof

An oxazoline-terminated polybutadiene and polybutadiene technology, applied in recycling technology, plastic recycling and other directions, can solve problems such as environmental and human health hazards, increase in waste plastics, and reduce impact strength, and achieve environmental Friendly, mild reaction conditions, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

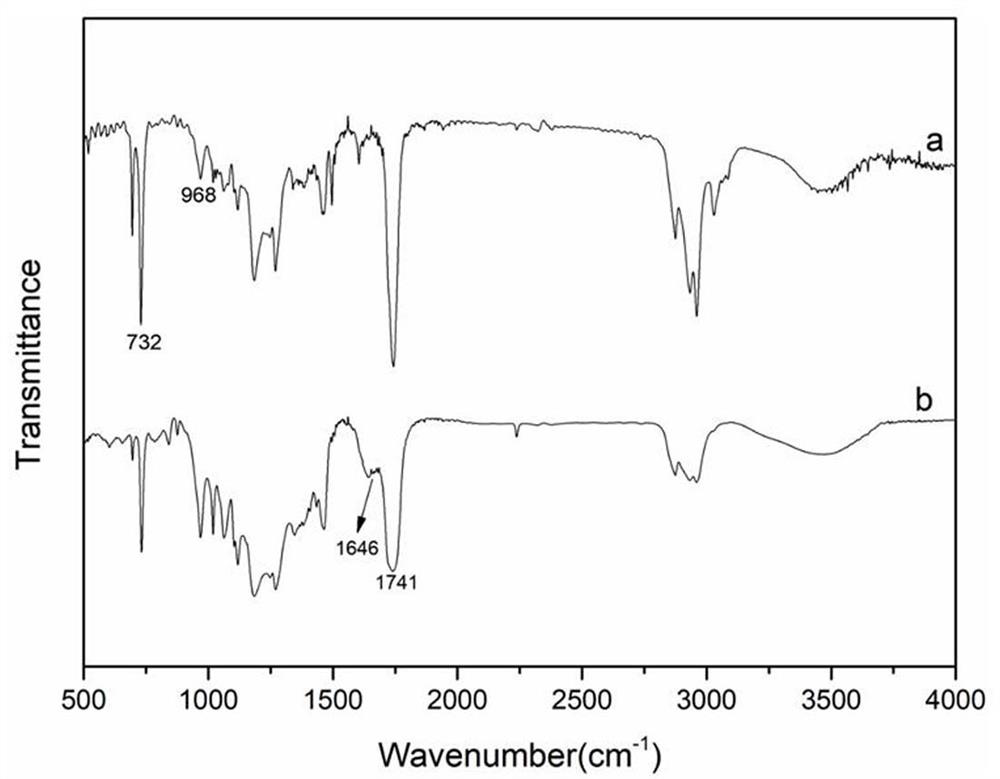

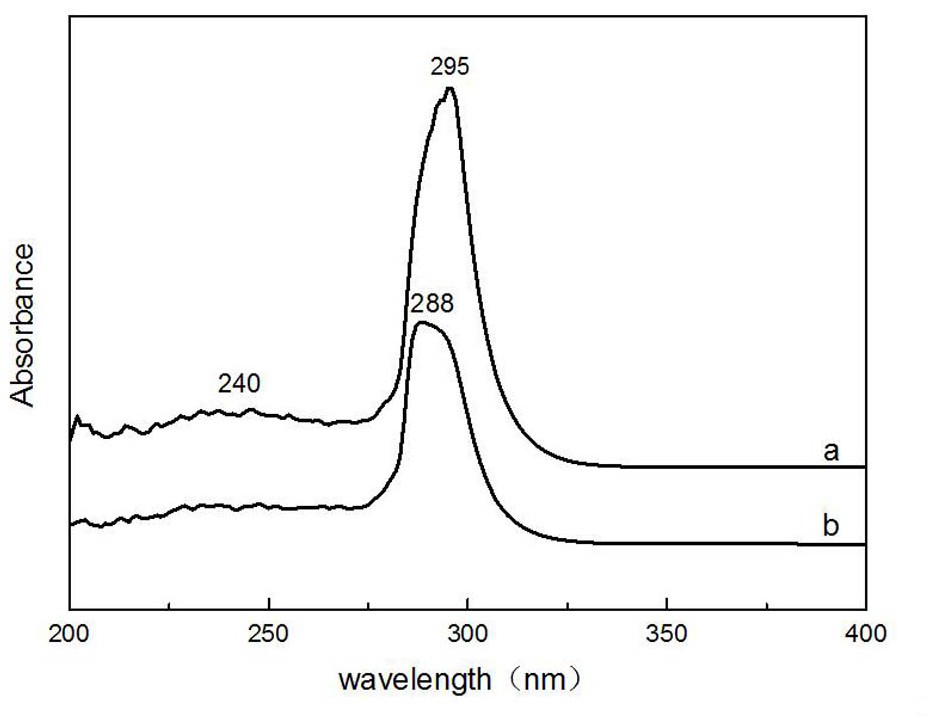

Embodiment 1

[0036] (1) Take by weighing 20.42g carboxyl-terminated polybutadiene and dissolve it in 50ml toluene to obtain carboxyl-terminated polybutadiene toluene solution;

[0037] (2) Slowly add 4.75 g of thionyl chloride into the above-mentioned carboxy-terminated polybutadiene toluene solution, and react with magnetic stirring at 40-50°C for 2-3 hours until the generation of bubbles stops;

[0038](3) A certain amount of ethanolamine was added into the system, and stirred for 2 hours by magnetic force, then 4A molecular sieve was added, and reacted for 3 hours at 120° C. to obtain an oxazoline-terminated polybutadiene compound. Wherein, the molar ratio of the added ethanolamine and carboxyl-terminated polybutadiene is 1:3.

Embodiment 2

[0040] (1) Take by weighing 20.42g carboxyl-terminated polybutadiene and dissolve it in 50ml toluene to obtain carboxyl-terminated polybutadiene toluene solution;

[0041] (2) Slowly add 4.75 g of thionyl chloride into the above-mentioned carboxy-terminated polybutadiene toluene solution, and react with magnetic stirring at 40-50°C for 2-3 hours until the generation of bubbles stops;

[0042] (3) A certain amount of ethanolamine was added to the system, and stirred for 2 hours by magnetic force, then 4A molecular sieve was added, and reacted for 5 hours at 120° C. to obtain an oxazoline-terminated polybutadiene compound. Wherein, the molar ratio of the added ethanolamine and carboxyl-terminated polybutadiene is 1:5.

Embodiment 3

[0044] (1) Take by weighing 20.42g carboxyl-terminated polybutadiene and dissolve it in 50ml toluene to obtain carboxyl-terminated polybutadiene toluene solution;

[0045] (2) Slowly add 4.75 g of thionyl chloride into the above-mentioned carboxy-terminated polybutadiene toluene solution, and react with magnetic stirring at 40-50°C for 2-3 hours until the generation of bubbles stops;

[0046] (3) A certain amount of ethanolamine was added into the system, and stirred for 2 hours by magnetic force, then 4A molecular sieve was added, and reacted for 7 hours at 120° C. to obtain an oxazoline-terminated polybutadiene compound. Wherein, the molar ratio of the added ethanolamine and carboxyl-terminated polybutadiene is 1:7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com