5A06 aluminum alloy pipe butt welding method

A welding method and technology for aluminum alloy pipes, which are applied in welding equipment, arc welding equipment, metal processing equipment and other directions, can solve the problems of uncontrolled appearance forming, easy generation of hot cracks and pores, etc., so as to improve the welding effect and quality, The effect of improving weld yield, high strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

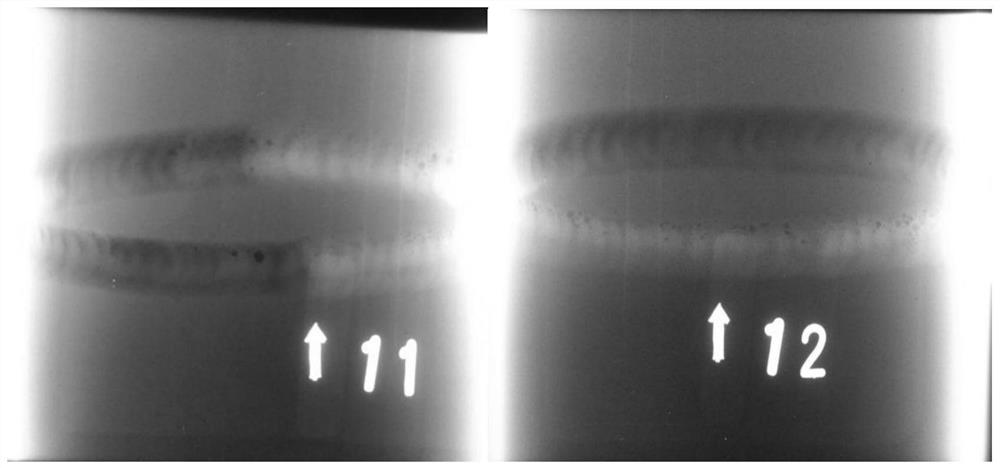

Image

Examples

Embodiment 1

[0030] A 5A06 aluminum alloy pipe butt welding method according to the present invention, wherein the wall thickness of the aluminum-magnesium alloy pipe is 5-10mm; the welding method includes pre-welding treatment, welding, and post-weld treatment; wherein the pre-weld treatment includes the workpiece Preheating, welding torch preheating, workpiece and welding wire cleaning, the welding process adopts argon tungsten arc welding, and the process parameters of the welding process are: the welding joint adopts a "V"-shaped butt joint groove, the welding level is 2 layers and 2 layers, and the bottoming The welding current is 150±5A, the cover welding current is 130±5A; the gas flow rate is 10-15L / min; the tungsten pole is cerium tungsten electrode, the diameter is 2.4-3.0mm; the welding wire grade is HS331, the model is SAIMg-5Ti, the welding wire The diameter is 2.4mm; the polarity of the power supply is AC.

[0031] Pre-weld treatment: The workpiece and welding wire are only c...

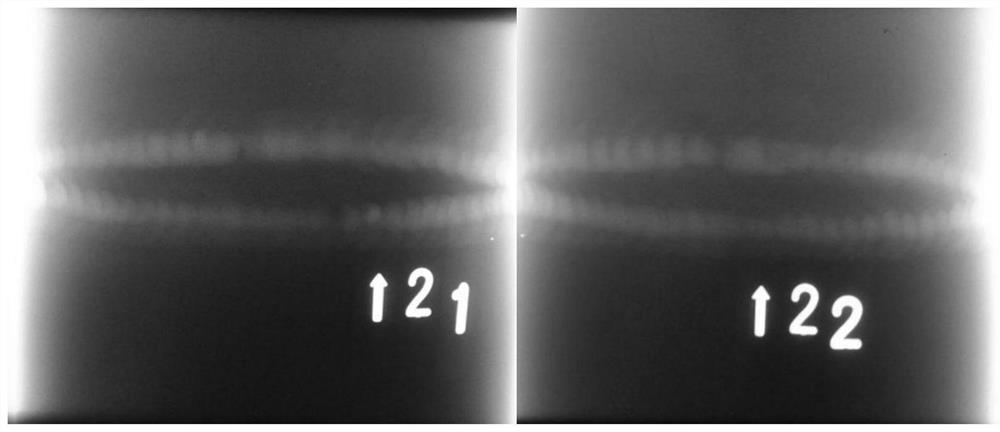

Embodiment 2

[0035] A 5A06 aluminum alloy pipe butt welding method according to the present invention, wherein the wall thickness of the aluminum-magnesium alloy pipe is 5-10mm; the welding method includes pre-welding treatment, welding, and post-weld treatment; wherein the pre-weld treatment includes the workpiece Preheating, welding torch preheating, workpiece and welding wire cleaning, the welding process adopts argon tungsten arc welding, and the process parameters of the welding process are: the welding joint adopts a "V"-shaped butt joint groove, the welding level is 2 layers and 2 layers, and the bottoming The welding current is 150±5A, the cover welding current is 130±5A; the gas flow rate is 10-15L / min; the tungsten pole is cerium tungsten electrode, the diameter is 2.4-3.0mm; the welding wire grade is HS331, the model is SAIMg-5Ti, the welding wire The diameter is 2.4mm; the polarity of the power supply is AC.

[0036] Pre-welding treatment: Preheating the welding torch in advanc...

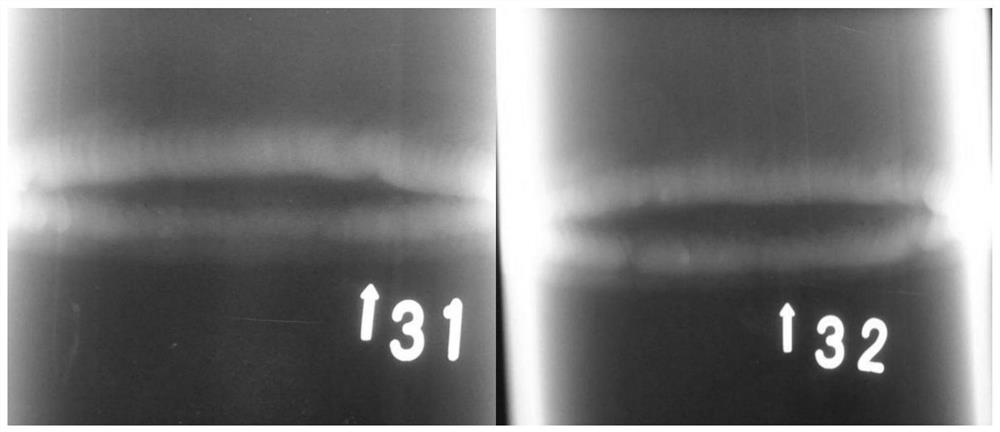

Embodiment 3

[0040]A 5A06 aluminum alloy pipe butt welding method of the present invention, wherein the wall thickness of the aluminum-magnesium alloy pipe is 5-10mm; the welding method includes pre-welding treatment, welding, and post-welding treatment; wherein, the pre-welding treatment includes the workpiece Preheating, welding torch preheating, workpiece and welding wire cleaning, the welding process adopts argon tungsten arc welding, and the process parameters of the welding process are: the welding joint adopts a "V"-shaped butt joint groove, the welding level is 2 layers and 2 layers, and the bottoming The welding current is 150±5A, the cover welding current is 130±5A; the gas flow rate is 10-15L / min; the tungsten pole is cerium tungsten electrode, the diameter is 2.4-3.0mm; the welding wire grade is HS331, the model is SAIMg-5Ti, the welding wire The diameter is 2.4mm; the polarity of the power supply is AC.

[0041] Pre-welding treatment: Preheating the welding torch in advance to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com