Lithium ion battery using crosslinked separator

A technology for separators and cross-linking reactions, applied in the manufacture of lithium batteries, secondary batteries, secondary batteries, etc., can solve the problem of insufficient electrolyte affinity or liquid retention, failure to meet permeability, and failure to meet high-speed requirements. Problems such as charging and discharging or heat resistance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 8 approach

[0460] [Viscoelastic Behavior (Viscoelasticity Measurement Version 3 Explained in Examples)]

[0461] The separator of the eighth embodiment includes a polyolefin microporous membrane, and regarding the viscoelasticity measurement (version 3) described in the examples, in the solid viscoelasticity measurement at a temperature of -50°C to 250°C, the storage modulus (E') the minimum value (E' min ) is 1.0MPa ~ 10MPa, the maximum value of E' (E' max ) is 100MPa~10,000MPa, and / or the minimum value of loss modulus (E") (E" min ) is 0.1MPa ~ 10MPa, the maximum value of E" (E" max ) is from 10MPa to 10,000MPa. If at 1.0MPa≤E' min ≤10MPa and 100MPa≤E' max ≤10,000MPa, and / or 0.1MPa≤E" min ≤10MPa and 10MPa≤E” max In the range of ≤10,000MPa, there is a tendency not only to take into account the closing function of the separator and the resistance to high-temperature membrane rupture, but also to avoid production defects in the manufacturing process of the separator or the storage ...

no. 9 approach

[0467] The partition of the ninth embodiment includes:

[0468] a microporous membrane comprising a silane-modified polyolefin; and

[0469] An inorganic porous layer comprising inorganic particles and a resin binder is disposed on at least one surface of the microporous membrane.

[0470] The separator of the ninth embodiment may include layers other than the microporous membrane and the inorganic porous layer as desired.

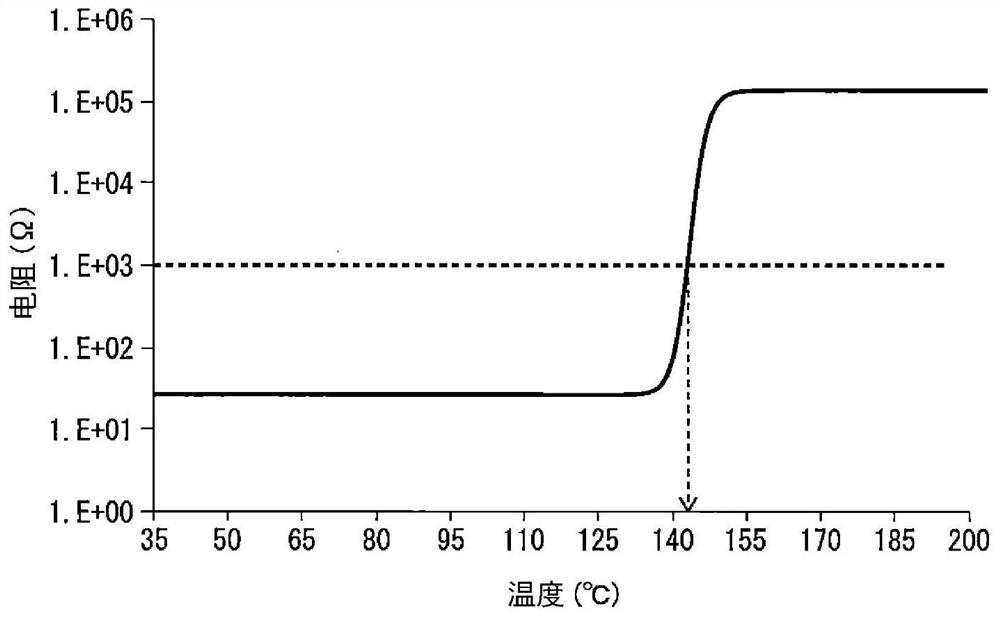

[0471] In the ninth embodiment, the combination of a microporous membrane comprising a silane-modified polyolefin and an inorganic porous layer balances the shutdown function at a temperature lower than 150° C. and the membrane rupture property at a higher temperature, and improves the cycle characteristics of the electrical storage device And the propensity for battery stabbing safety. It is presumed that since the silane-modified polyolefin in the microporous membrane is silane-crosslinkable, once the silane crosslinking occurs, the viscosity of the re...

no. 10 approach

[0489] A separator for an electrical storage device (hereinafter also simply referred to as a "separator") according to a tenth embodiment includes a first porous layer (A layer) containing silane-modified polyolefin and capable of forming a cross-linked structure, and a second porous layer containing inorganic particles. Porous layer (layer B). The A layer and the B layer are each a single layer or a multilayer. The B layer is formed only on one surface of the A layer or on both surfaces.

[0490] In LIB, which is a typical example of an electrical storage device, lithium (Li) ions reciprocate between positive and negative electrodes. Therefore, by arranging the separator including the A layer and the B layer between the positive and negative electrodes, Li ions can be moved at a relatively high speed between the positive and negative electrodes while avoiding contact between the positive and negative electrodes.

[0491] (ratio of thickness)

[0492] The layer A functions...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com