Simple perovskite solar cell packaging structure and manufacturing method thereof

A solar cell and packaging structure technology, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve the problems that the testing and connection of perovskite solar cells cannot be completed, and achieve convenient testing and connection , Improved device stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

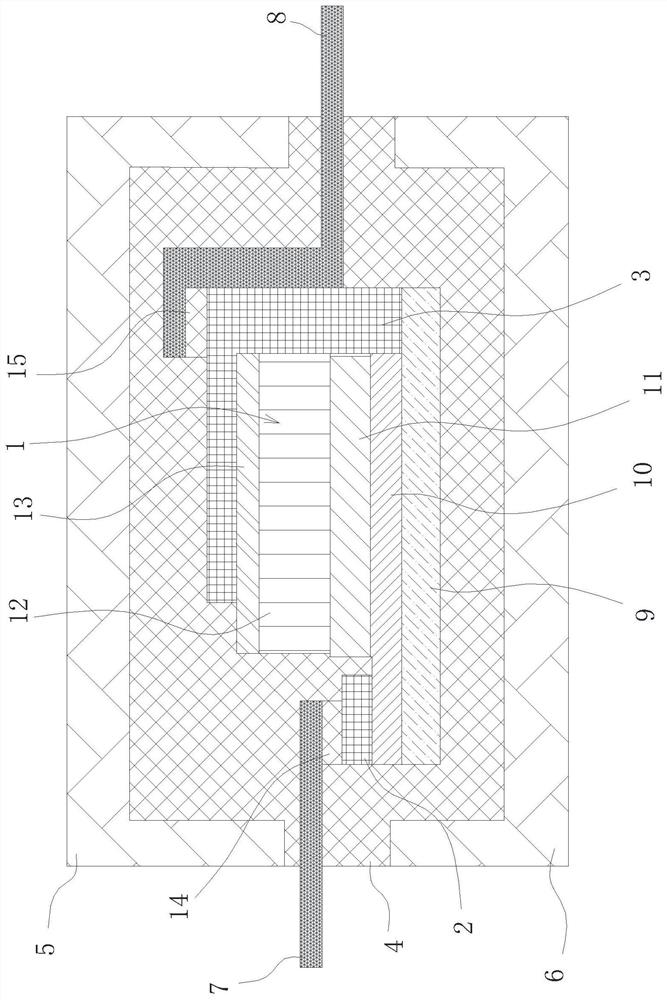

[0025] A simple perovskite solar cell packaging structure, comprising a perovskite solar cell 1, the perovskite solar cell 1 is provided with a first metal electrode 2 and a second metal electrode 3, the perovskite solar cell 1 Encapsulation material 4 is wrapped outside, the upper backplane 5 and the lower backplane 6 are sandwiched outside the encapsulation material 4, the first metal electrode 2 is connected to the first metal lead 7, and the second metal electrode 3 is connected to the second metal The leads 8 , the first metal leads 7 and the second metal leads 8 respectively extend out of the packaging material 4 and are located outside the upper backplane 5 and the lower backplane 6 .

[0026] After the perovskite solar cell 1 is packaged, it can effectively avoid the contact of external water and oxygen, and the stability is significantly improved; at the same time, the metal lead in contact with the electrode of the perovskite solar cell 1 can facilitate the testing an...

Embodiment 2

[0034]A method for manufacturing the perovskite solar cell encapsulation structure as described in Embodiment 1, the first conductive glue 14 and the second conductive glue 15 are respectively applied on the first metal electrode 2 and the second metal electrode 3, and respectively Contact the first metal lead 7 and the second metal lead 8 with the first conductive glue 14 and the second conductive glue 15 to complete the first metal lead 7 and the first metal electrode 2 and the second metal lead 8 and the second metal electrode 3 connection, the encapsulation material 4 is wrapped outside the perovskite solar cell 1, the first metal lead 7 and the second metal lead 8 pass out of the encapsulation material 4, and the upper backplane 5 and the lower backplane 6 are clipped from two directions up and down. Hold the packaging material 4, the first metal lead 7 and the second metal lead 8 pass through between the upper backplane 5 and the lower backplane 6, complete the fixation, ...

Embodiment 3

[0037] A method for manufacturing the perovskite solar cell encapsulation structure as described in embodiment 1,

[0038] Partially etched ITO conductive glass was used as the substrate 9, followed by ultrasonic cleaning with deionized water, ethanol, acetone and isopropanol respectively, and after drying with nitrogen, placed in an ozone cleaner for 15 minutes.

[0039] Then use the sol-gel method to prepare the electron transport layer, first prepare 5% by mass SnO 2 Colloidal precursor solution and stir evenly, drop 70 microliters onto the ITO substrate 9, the substrate 9 is 2.5*2.5cm, spin-coat in the air, spin-coat at 4000rpm for 30 seconds, and then move to the heating Heat on stage at 150°C for 1 hour. After cooling to room temperature, move it to an ozone cleaner, take it out immediately after processing for 15 minutes, and put it in a glove box for use.

[0040] The preparation of the perovskite layer 12 adopts a one-step method. Firstly, the perovskite precursor s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com