Method for extracting fish scale polysaccharide by adopting dynamic high-pressure microjet pretreatment

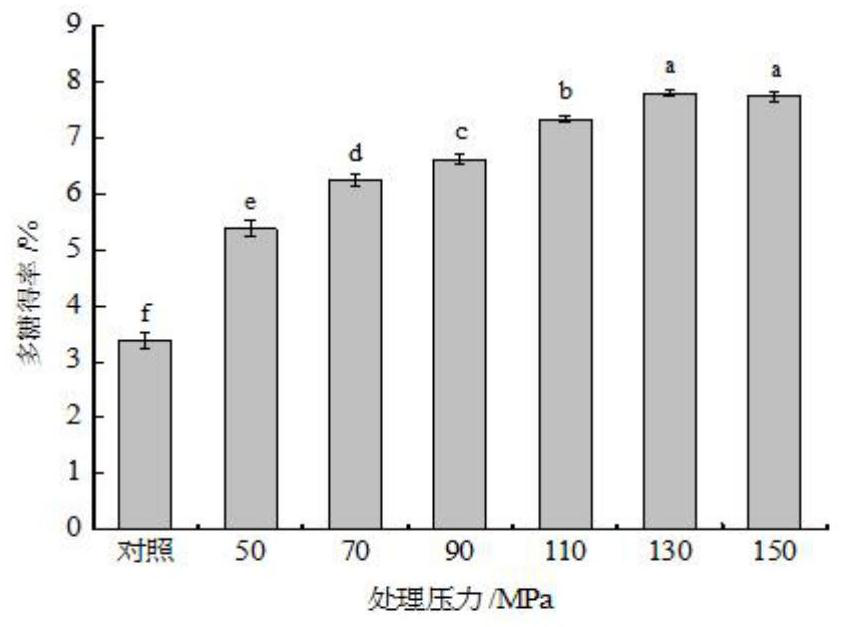

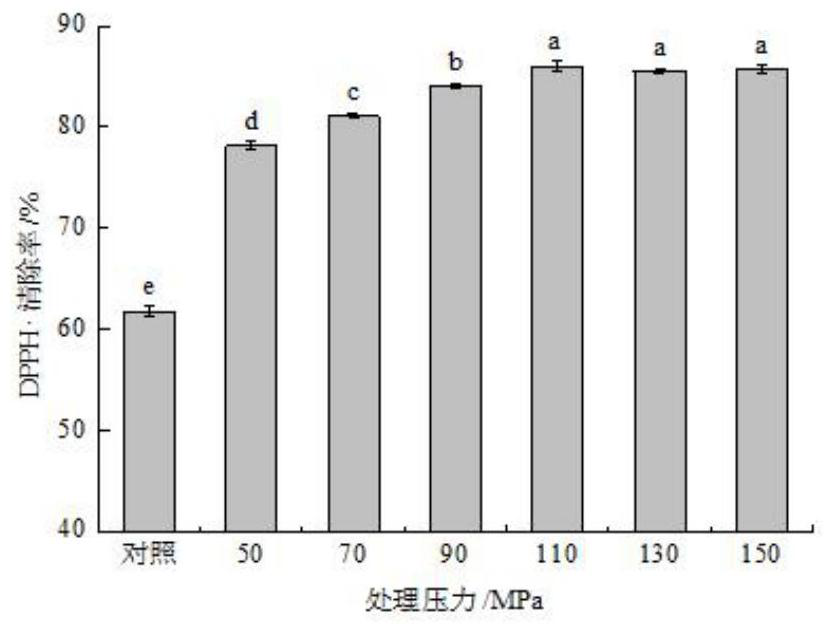

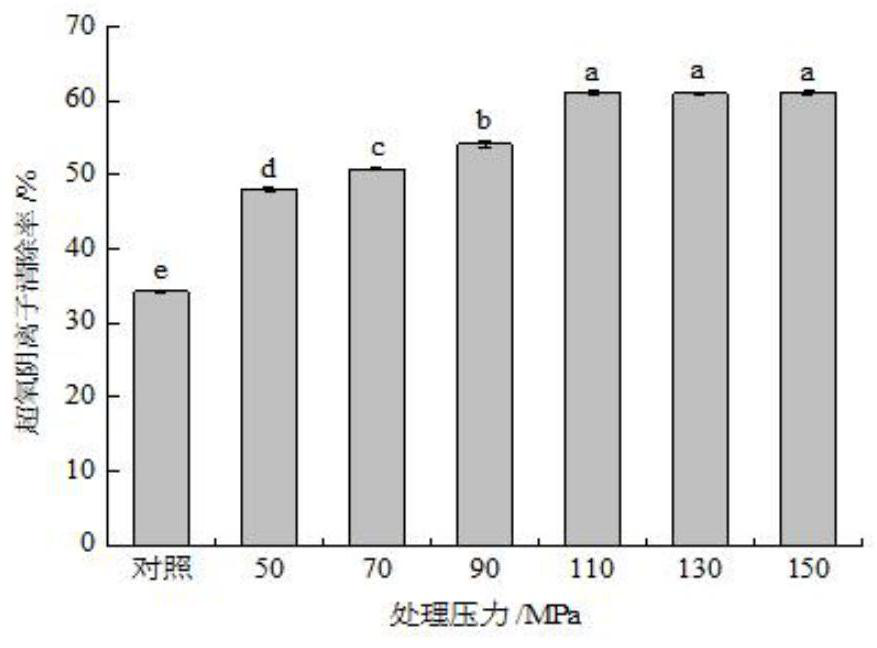

A high-pressure micro-jet, pre-treatment technology, applied in the direction of antitoxins, drug combinations, etc., to achieve the effect of improving the extraction yield and in vitro antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for extracting polysaccharides from fish scales using dynamic high-pressure micro-fluidic pretreatment, comprising the following steps:

[0048] (1) Clean the fresh carp scales, decalcify them, add the scales into the phosphoric acid solution, the mass volume ratio of the scales to the phosphoric acid solution is 1g: 30mL, the concentration of the phosphoric acid solution is 0.6mol / L, at a speed of 60r / min Stir at lower temperature for 40 minutes, filter through a 100-mesh filter cloth to obtain decalcified fish scales, then dry at 48°C for 2 hours, and pulverize until the particle size is 80 mesh to obtain fish scale powder, which is set aside;

[0049] (2) Mix the fish scale powder obtained in step (1) with water, the mass volume ratio of fish scale powder and water is 1g:20ml, stir evenly, the stirring speed is 200r / min, and the stirring time is 1min, and then use a dynamic high-pressure nano homogenizer Treat 2 times, each treatment pressure is 50MPa, treat...

Embodiment 2

[0052] A method for extracting polysaccharides from fish scales using dynamic high-pressure micro-fluidic pretreatment, comprising the following steps:

[0053] (1) Fresh grass carp fish scales are washed, decalcified, fish scales are added in phosphoric acid solution, the mass volume ratio of fish scales and phosphoric acid solution is 1g: 40mL, the concentration of described phosphoric acid solution is 0.8mol / L, at 80r / min Stir for 50 minutes at a rotating speed of 150 mesh, filter through a 150-mesh filter cloth to obtain decalcified fish scales, then dry at a temperature of 50°C for 2.2 hours, and pulverize until the particle size is 100 mesh to obtain fish scale powder. spare;

[0054] (2) Mix the fish scale powder obtained in step (1) with water, the mass volume ratio of fish scale powder and water is 1g: 30ml, stir evenly, the stirring speed is 250r / min, the stirring time is 1.5min, and then use dynamic high pressure nano homogenizer The instrument was treated 3 times,...

Embodiment 3

[0057] A method for extracting polysaccharides from fish scales using dynamic high-pressure micro-fluidic pretreatment, comprising the following steps:

[0058] (1) Fresh carp fish scales are washed, decalcified, and fish scales are added in the phosphoric acid solution, the mass volume ratio of fish scales and phosphoric acid solution is 1g: 50mL, the concentration of described phosphoric acid solution is 1.2mol / L, at 100r / min Stir for 60 minutes at a rotating speed of 200 mesh, filter through a 200-mesh filter cloth to obtain decalcified fish scales, then dry at a temperature of 53°C for 2.5 hours, and pulverize until the particle size is 120 mesh to obtain fish scale powder. spare;

[0059] (2) Mix the fish scale powder obtained in step (1) with water, the mass volume ratio of fish scale powder and water is 1g:40ml, stir evenly, the stirring speed is 300r / min, and the stirring time is 2min, and then use a dynamic high-pressure nano homogenizer Treat 4 times, each treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com