Preparation method of high-strength nanofiber membrane wound dressing

A technology for nanofiber membranes and wound dressings, applied in the field of high-strength GO@ICG/PCM/CA/PCL nanofiber membranes, can solve the problems of limiting the practical application of wound dressings and poor mechanical properties of fiber membranes, and promote good distribution , enhanced compatibility, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

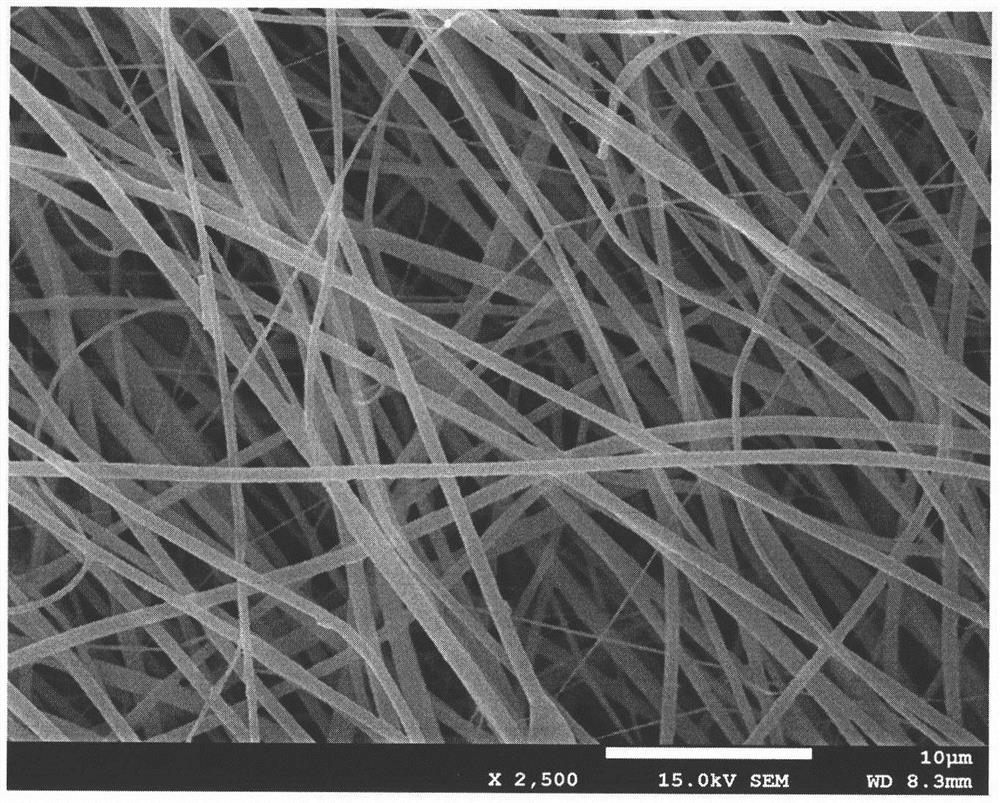

[0032] Using Japan Hitachi S-4800 Field Emission Scanning Electron Microscope (FE-SEM), the surface morphology of the prepared fiber membrane was observed. Before the test, the sample was sprayed with gold to enhance the conductivity of the surface and accelerate The voltage was 5kV, and the surface morphology of the obtained GO@ICG / PCM / CA / PCL nanofiber membrane was observed, which confirmed that the membrane material prepared by the present invention had a core-shell structure. This time, the optical image profilometry method can be used to visually see the surface structure of the composite film.

Embodiment 2

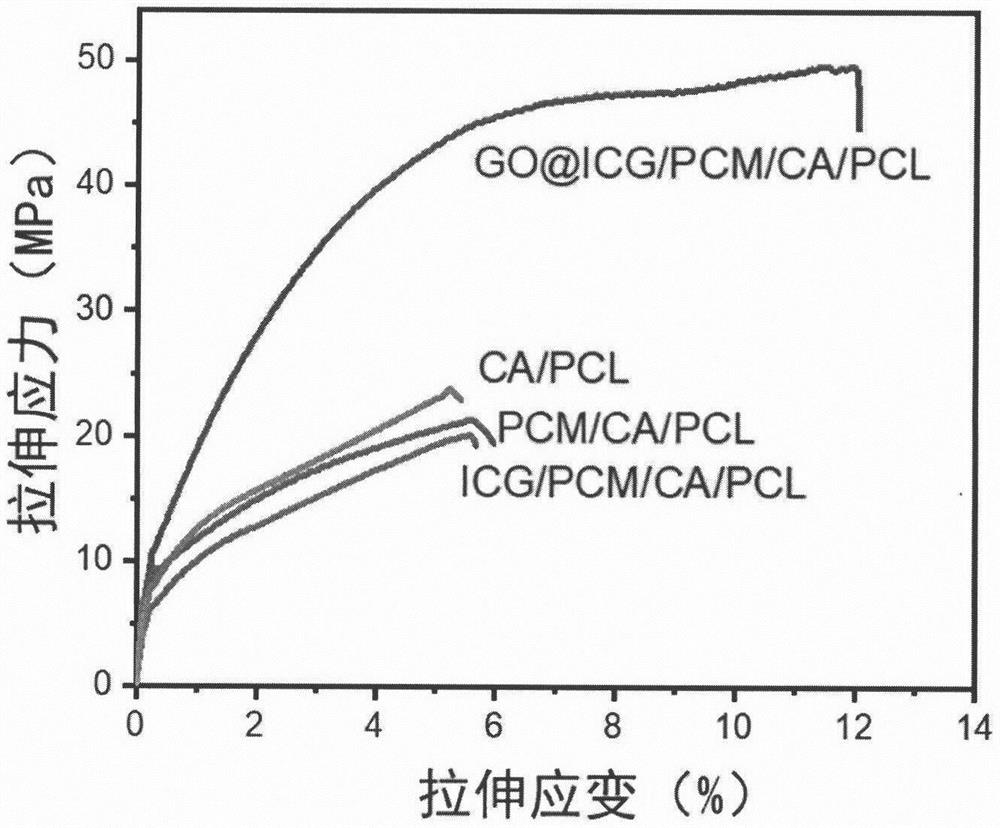

[0034] The tensile stress and strain of PU, PCL and PU-PCL fiber membranes containing different PCM contents were tested at room temperature by Shenzhen Sansi Electronics universal testing machine. Cut the fiber membrane sample into a rectangle of 25mm×5mm, measure the average thickness of the sample (three times) with a screw micrometer, test the maximum force of 500N, and the tensile rate of 2mm / min. Calculate the Young's modulus of the fibrous membrane from the linear region of the stress-strain curve at 5% strain. Compared with the pure CA / PCL fiber membrane, the addition of indocyanine green (ICG) phase change material (PCM) tetradecyl alcohol has little effect on the mechanical properties of the fiber membrane, while the addition of graphene oxide greatly improves the mechanical properties of the fiber membrane. Mechanical strength of CA / PCL composite fibers. The tensile strength of fiber membrane GO@ICG / PCM / CA / PCL is enhanced from 20MPa of fiber membrane CA / PCL to 50MP...

Embodiment 3

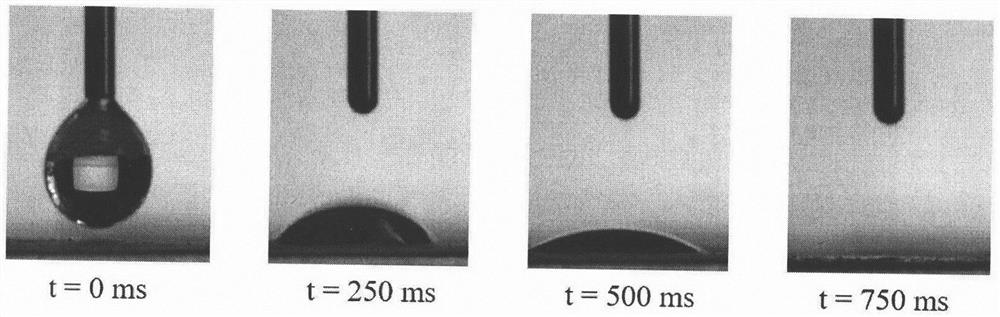

[0036]The hydrophilic and hydrophobic properties of the fiber membrane, that is, the surface wettability, can be measured by the contact size of the fiber membrane with deionized water. Using a contact angle measuring instrument (JC2000D1), Shanghai Zhongchen Company, China, the wettability of the surface of the nanocomposite fiber membrane soaked in different concentrations of GSH solution and ZIF-8 was tested. Lay the membrane on the test platform, aim the camera at the platform to ensure that the complete picture can be captured, fill the injection needle with deionized water, push out 2 microliters of deionized water each time, so that the droplets stay on the surface of the membrane, Using the principle of "three-point fixed circle", the tangent point between the droplet and the membrane surface and the highest point of the droplet are determined manually, and the contact angle angle is automatically generated by the measuring instrument to determine the wettability of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com