Turbosuperchager forced lubrication and cooling protection device

A turbocharger and forced lubrication technology, applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problems of frequent engine start and stop, user misoperation, dry grinding of the turbocharger rotor system, etc., to solve the problem of supply Oil or water lag time is too long, the structure is simple, and the effect of reducing the number of parts and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

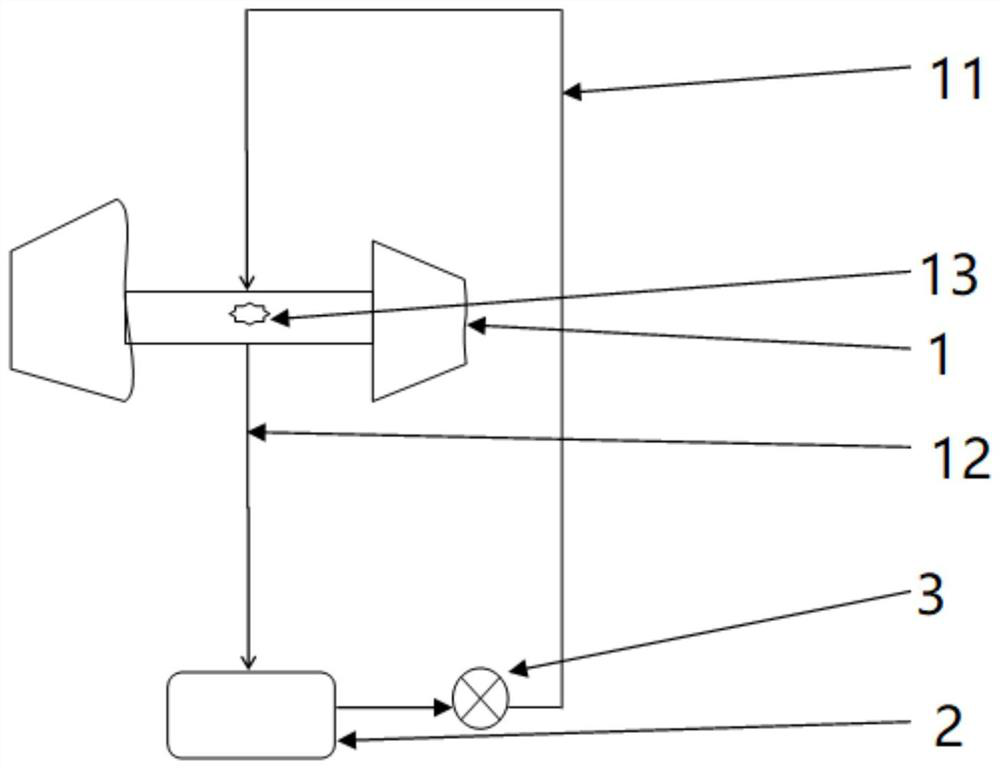

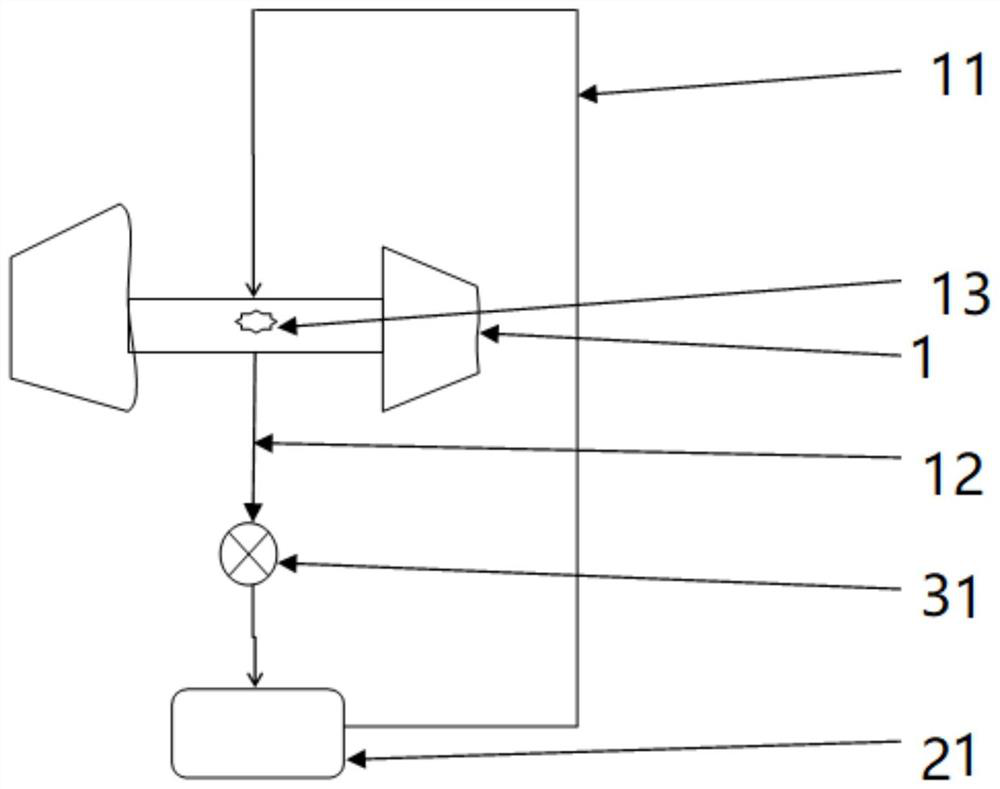

[0024] The invention provides a turbocharger forced lubrication cooling protection device, such as figure 1 , including a supercharger 1, and an input pipeline 11 and an output pipeline 12 respectively connected to the input end and the output end of the supercharger 1, and the input pipeline 11 and the output pipeline 12 are respectively connected to the engine coolant main pipeline 2. An electronic pump 3 is arranged on the input pipeline 11, and the electronic pump 3 is set to be normally open. The electronic pump 3 can also be arranged on the supercharger output pipeline 12, such as image 3 shown. The turbocharger forced lubrication protection device is independent from the main lubrication system of the engine, and the design of the electronic pump 3 is added. The electronic pump 3 is normally open, that is, when the engine is running, the electronic pump 3 is always running, and the electronic pump 3 can be arranged in the input pipe. Road 11 is oil or water for lubri...

Embodiment 2

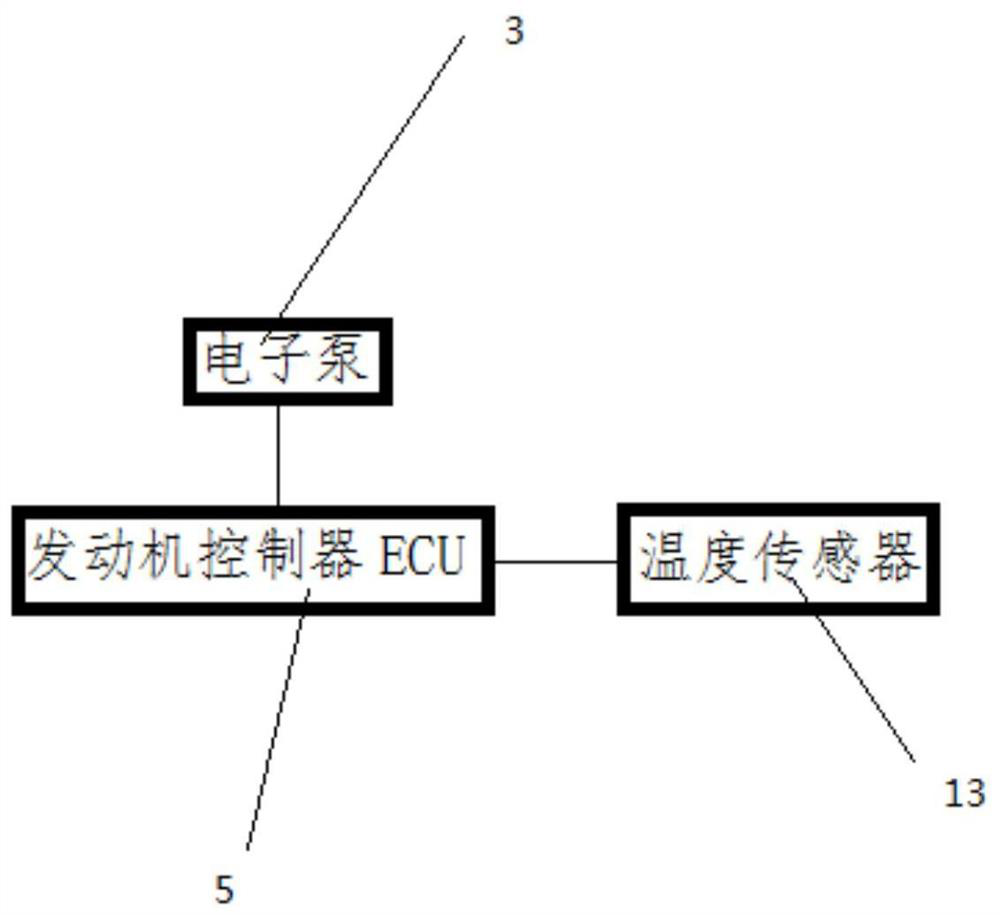

[0026] On the basis of Example 1, such as figure 1 and figure 2 , also includes an engine controller ECU5 and a temperature sensor 13, the temperature sensor 13 is arranged on the bearing of the supercharger 1, and the engine controller ECU5 is electrically connected with the electronic pump 3 and the temperature sensor 13 respectively.

[0027] When the engine controller ECU5 received the starting signal of the engine 4, the engine controller ECU5 controlled the electronic pump 3 to start running to shorten the fuel supply delay time of the supercharger 1; when the engine 4 was running normally, the electronic pump 3 was in a normally open state, Engine calibration determines the rotational speed; when the engine 4 is stopped, the electronic pump 3 continues to run for a period of time, such as 30s, thereby reducing the temperature of the exhaust system and bearing temperature, so as to protect the supercharger 1 . By adding the supercharger bearing temperature sensor 13, a...

Embodiment 3

[0029] On the basis of the above examples, if Figure 4 and figure 2 , the electronic pump 3 is an electronic oil pump 32, and the input pipeline 11 and the output pipeline 12 are respectively connected to the outlet and the inlet of the engine oil pan 22.

[0030] In the present embodiment, the control steps of engine controller ECU5 are as follows:

[0031] S1: The engine controller ECU5 receives the start signal of the engine 4 .

[0032] S2: The engine controller ECU5 outputs a command, and the electronic oil pump 32 starts to rotate at a rated speed of 1500 rpm.

[0033] S3: The engine controller ECU5 receives the signal from the temperature sensor 13, and outputs instructions to the electronic oil pump 32 according to the temperature data. When the temperature is lower than 180°C, the speed of the electronic oil pump 3 is maintained at 1500 rpm; when the temperature is 180°C-210°C When the temperature is higher, the rotation speed of the electronic oil pump 3 is chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com