Mixed metal salt formula for increasing biogas yield of cassava vinasse waste liquid through fermentation

A technology of mixing metal and cassava distiller's grains, which is applied in the direction of fermentation, waste fuel, and the use of additive compounds to stimulate growth, etc., to achieve the effect of increasing diversity, sufficient elements, and promoting conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

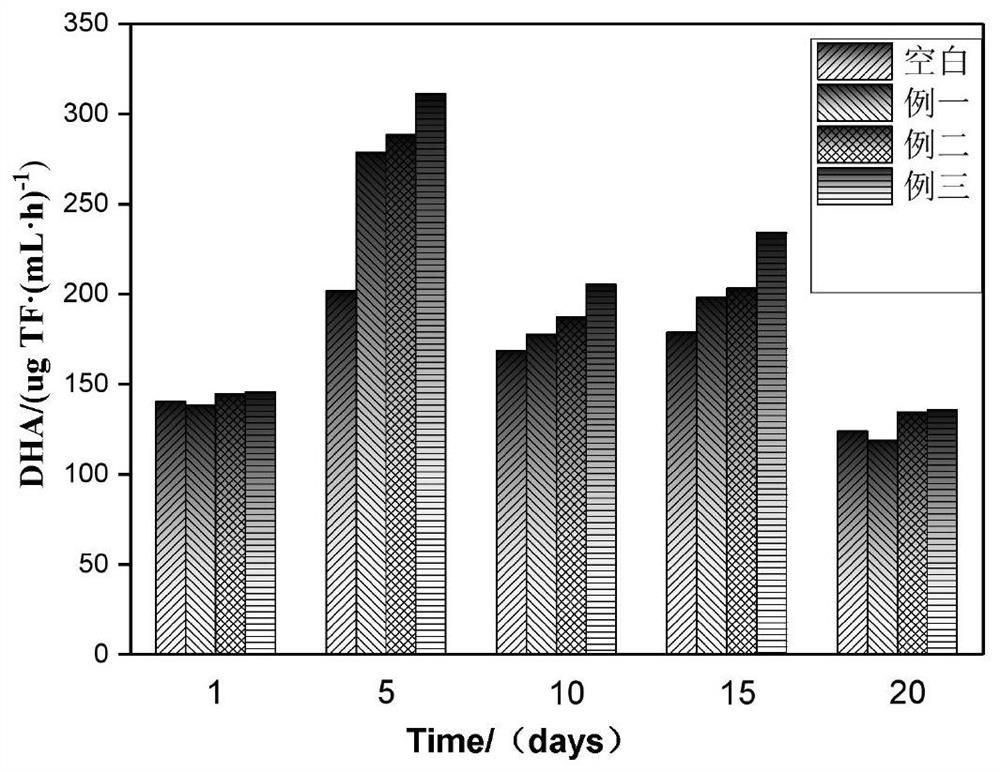

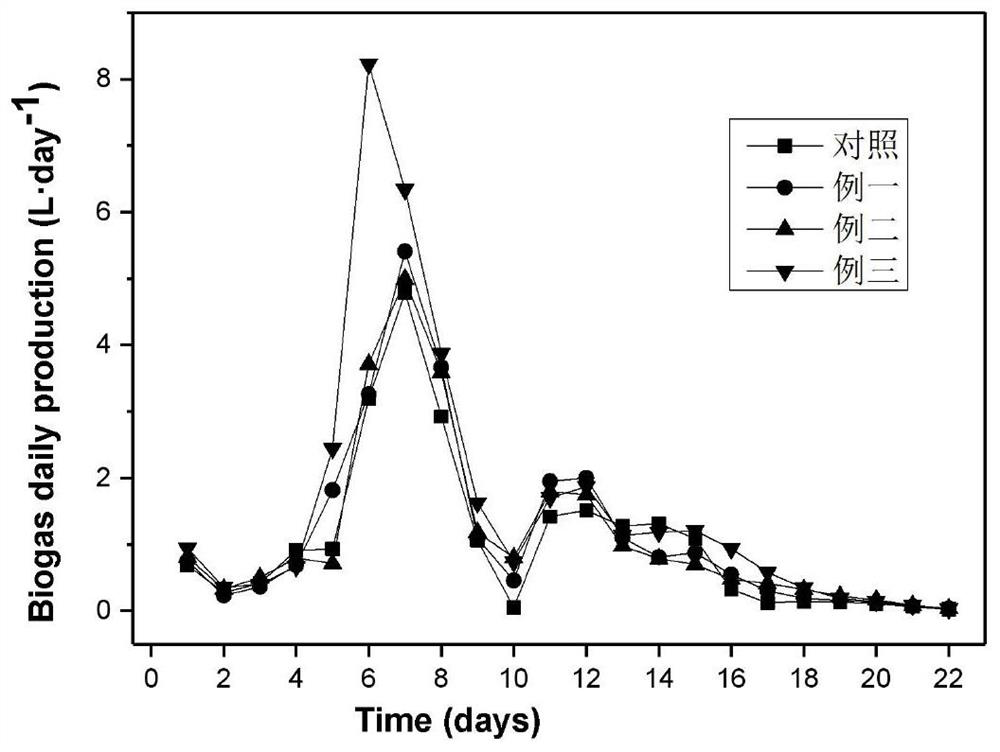

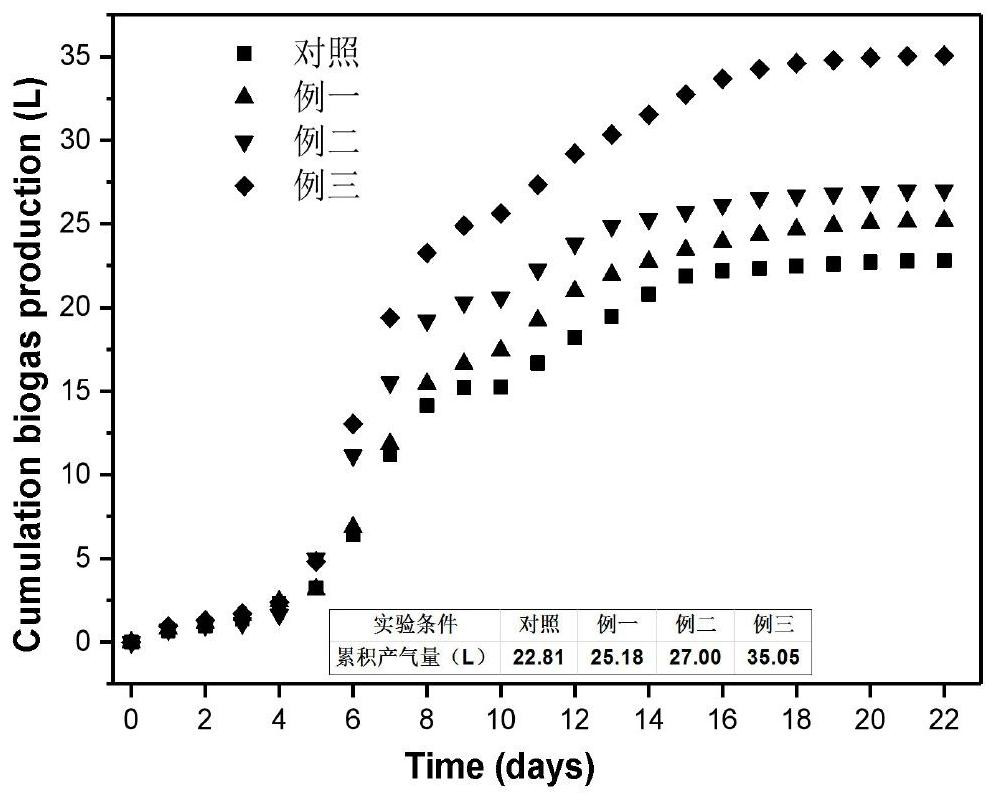

Embodiment 1

[0068] Add 250 mg of ferrous chloride tetrahydrate, 1 mg of cobalt chloride hexahydrate, 5 mg of nickel chloride hexahydrate, 1 g of sodium acetate, 1 g of potassium dihydrogen phosphate, 1 g of dipotassium hydrogen phosphate, and magnesium sulfate in 1 L of fermentation broth. 50mg, manganese sulfate monohydrate 1mg, zinc sulfate monohydrate 0.1mg, calcium chloride 0.1mg and ammonium chloride 20mg mixed metal salt, add 1L of the above-mentioned mixed metal salt fermentation broth and 1L cassava distiller's waste liquid Placed in the BioprocessSimulator fermenter, pH=7.3 in the fermenter, COD=25500mg·L -1 , under the same experimental conditions, the cumulative biogas production was measured to be 25.18L, which was 10.39% higher than that of Comparative Example 1, the COD removal rate was raised to 83.52%, and the unit VS gas production was raised to 2.24L·g -1 .

Embodiment 2

[0070] In 1L of fermentation broth, add 400 mg of ferrous chloride tetrahydrate, 5 mg of cobalt chloride hexahydrate, 30 mg of nickel chloride hexahydrate, 3 g of sodium acetate, 0.5 g of potassium dihydrogen phosphate, 0.50 g of dipotassium hydrogen phosphate, Magnesium sulfate 150mg, manganese sulfate monohydrate 2mg, zinc sulfate monohydrate 0.6mg, calcium chloride 1.5mg and ammonium chloride 50mg are composed of a mixed metal salt, 1L of the fermentation broth added with the above mixed metal salt and 1L of cassava distiller's grains liquid together in the BioprocessSimulator fermenter, pH = 7.3 in the fermenter, COD = 23000mg L -1 , under the same experimental conditions, the cumulative biogas production was measured to be 27.00L, which was 18.37% higher than that of Comparative Example 1, the COD removal rate was raised to 86.66%, and the unit VS gas production was raised to 2.36L·g -1 .

Embodiment 3

[0072] In 1L of fermentation broth, add 355 mg of ferrous chloride tetrahydrate, 4 mg of cobalt chloride hexahydrate, 20 mg of nickel chloride hexahydrate, 2 g of sodium acetate, 0.4 g of potassium dihydrogen phosphate, 0.4 g of dipotassium hydrogen phosphate, Magnesium sulfate 100mg, manganese sulfate monohydrate 1.5mg, zinc sulfate monohydrate 0.5mg, calcium chloride 1mg and ammonium chloride 60mg are composed of a mixed metal salt, add 1L of the fermentation broth with the above mixed metal salt and 1L cassava distiller's grains liquid together in the BioprocessSimulator fermenter, pH=7.4 in the fermenter, COD=25000mg·L -1 Under the same experimental conditions, the cumulative biogas production was measured to be 35.05L, which was 53.66% higher than that of Comparative Example 1, the COD removal rate was increased to 90.02%, and the unit VS gas production was increased to 2.53L g -1 .

[0073] Table 3 Effects of this mixed metal salt additive on various indicators of cassa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com