Water-resistant calcium sulfonate-based lubricating grease and preparation method thereof

A calcium sulfonate-based lubricating grease and calcium sulfonate technology, which is applied in the field of lubricating grease, can solve the problems of easy lack of oil and can not solve the problem of calcium sulfonate-based lubricating grease becoming dry when it encounters water, so as to improve thermal stability , Improve high temperature anti-oxidation effect, excellent water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

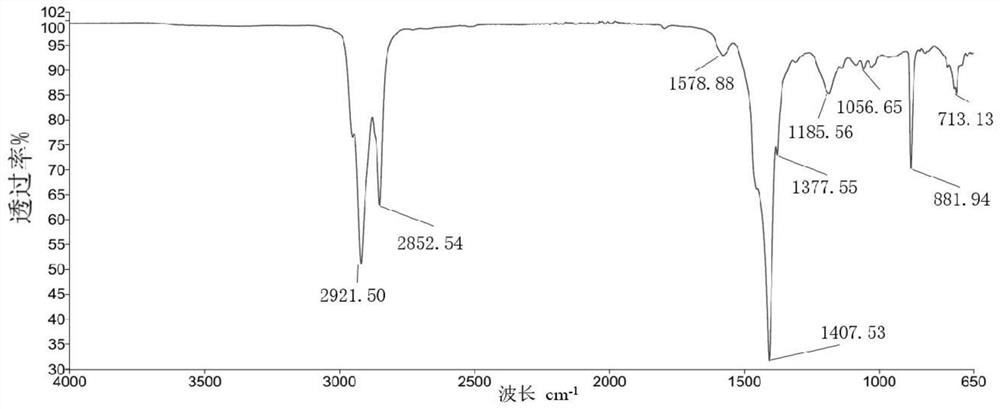

Image

Examples

Embodiment 1~8

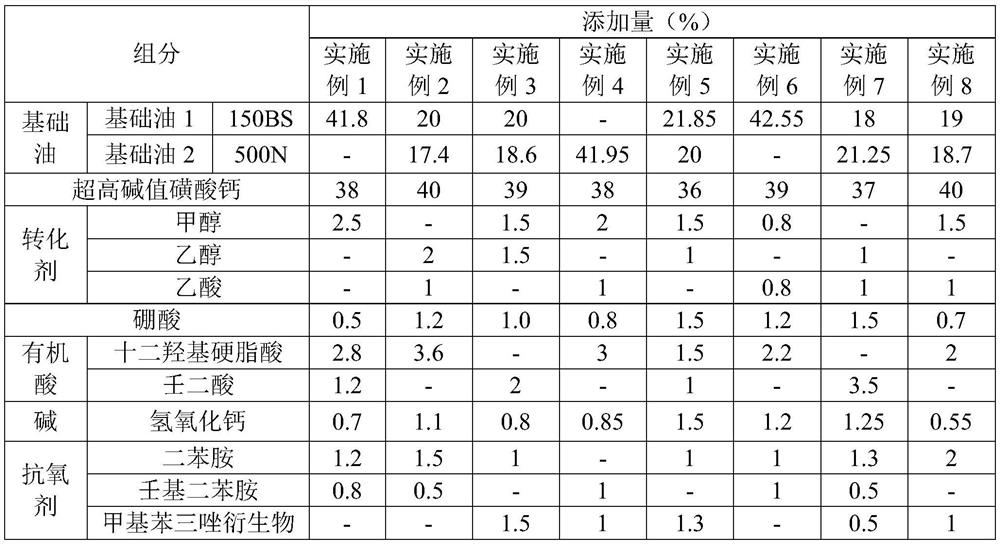

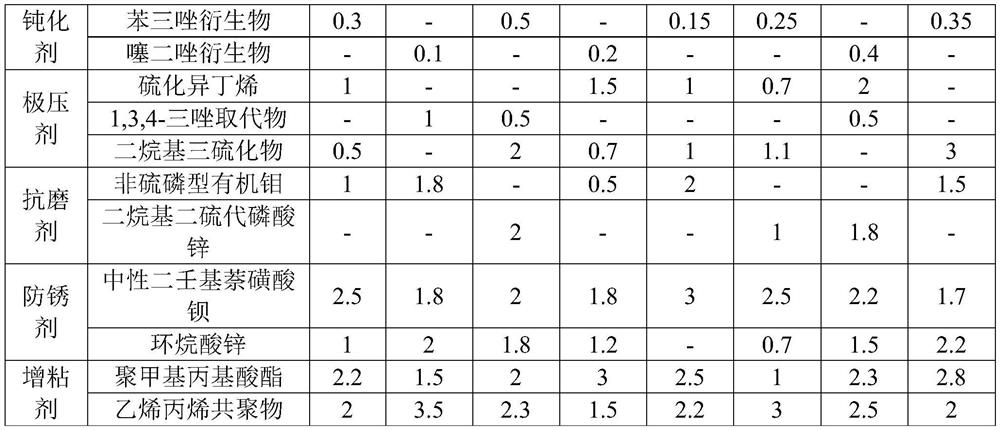

[0089] The specific components and component contents (in terms of mass percentage) of the water-resistant calcium sulfonate-based grease provided in Examples 1 to 8 are shown in Table 1 (wherein "-" represents that this embodiment does not add this group Minute):

[0090] Table 1

[0091]

[0092]

[0093] The preparation method of the anti-water type calcium sulfonate base lubricating grease that embodiment 1~8 provides comprises the following steps:

[0094] (1) Material mixing: mix ultra-high alkalinity calcium sulfonate and part of the base oil at 20-50°C for 5-15 minutes to obtain a mixed material;

[0095] (2) Conversion reaction: mix the mixed material obtained in step (1) with the conversion agent, heat to 80-90° C., and react with triple stirring for 120-150 minutes to obtain the converted mixed material;

[0096] (3) Composite reaction: mix the conversion mixture obtained in step (2) with alkali, organic acid, and boric acid, and heat to 90-100° C. for 30-60...

Embodiment 9

[0105] This example provides a water-resistant calcium sulfonate-based grease, the only difference from Example 1 is that the base oil 1 has a kinematic viscosity of 80mm at 40°C 2 / s, other component content and preparation method are with embodiment 1.

Embodiment 10

[0107] This example provides a water-resistant calcium sulfonate-based lubricating grease, the only difference from Example 1 is that the kinematic viscosity of the base oil 1 at 40°C is 500mm 2 / s, other component content and preparation method are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cone penetration | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com