Adhesive composition, packaging film, and organic electronic device containing packaging film

A technology of organic electronic components and adhesives, applied in the direction of adhesive types, electrical solid devices, ester copolymer adhesives, etc., can solve problems to be studied, etc., to avoid material deposition, high transparency, and improve peel strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

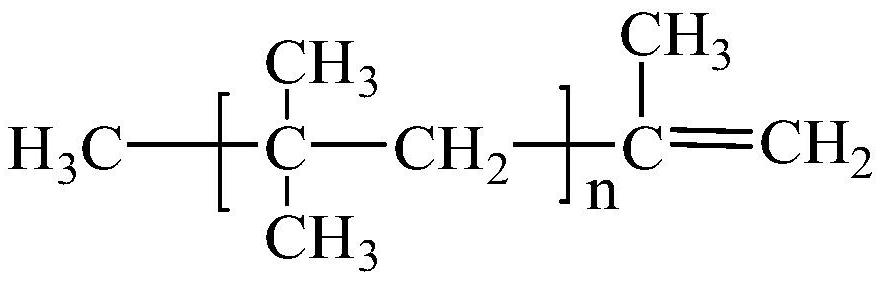

[0069] (1) Preparation of siloxanated polyisobutylene

[0070] Add 50 parts by weight of heptamethylhydrotrisiloxane and toluene into a four-necked flask equipped with a stirrer, a thermometer and a reflux condenser. Under the condition that nitrogen is the protective gas, add 75 parts by weight of high-activity polyisobutylene (LPIB, molecular weight is 400) with a funnel and stir, add 1 part by weight of isopropyl alcohol of chloroplatinic acid as a catalyst, control the reaction temperature at 90 ° C, and react About 6 hours. Then the product is distilled under reduced pressure to remove low boilers to generate siloxanated polyisobutene.

[0071] (2) Preparation of acrylate copolymer

[0072] Add 90 parts by weight of butyl methacrylate, 5 parts by weight of 2-hydroxyethyl acrylate, 4 parts of acrylonitrile monomer mixture and 1 part by weight of glycidyl methacrylate crosslinking agent to the cooling system To facilitate the reflux of nitrogen and temperature control in...

Embodiment 2

[0081] (1) The preparation of siloxanated polyisobutylene is the same as in Example 1, wherein the molecular weight of the polyisobutylene used is 950.

[0082] (2) The preparation of acrylate copolymer is the same as in Example 1.

[0083] (3) Preparation of adhesive composition

[0084] 5 parts by weight of silica was added to toluene, stirred and mixed, and then dispersed with an ultrasonic generator for about 1 hour, thereby preparing a dispersion with a solid content of 5% by weight.

[0085] 4.8 parts by weight of siliconized polyisobutylene resin, 1 part by weight of hydrogenated petroleum resin, and 4.6 parts by weight of acrylate copolymer were added to toluene so that the solid content was 15% by weight. Add 1.5 parts by weight of silica dispersion, 2.8 parts by weight of γ-aminopropyltriethoxysilane (KH550), 0.05 parts by weight of toluene diisocyanate (TDI), and dilute the resulting mixture to a solid content of 10%. An adhesive composition is obtained.

[0086]...

Embodiment 3

[0089] (1) The preparation of siloxanated polyisobutylene is the same as that in Example 1, wherein the molecular weight of the polyisobutylene used is 1400.

[0090] (2) The preparation of acrylate copolymer is the same as in Example 1.

[0091] (3) Preparation of adhesive composition

[0092] 5 parts by weight of titanium dioxide was added to toluene, stirred and mixed, and then dispersed with an ultrasonic generator for about 1 hour, thereby preparing a dispersion with a solid content of 5% by weight.

[0093] 13 parts by weight of siliconized polyisobutylene resin, 6 parts by weight of hydrogenated petroleum resin, and 10 parts by weight of acrylate copolymer were added to toluene so that the solid content was 30% by weight. Add 4.3 parts by weight of titanium dioxide dispersion, 4.5 parts by weight of γ-acetoacetate propyl trimethoxysilane, 0.02 parts by weight of toluene diisocyanate (TDI), and dilute the resulting mixture to a solid content of 27%, to obtain an adhesiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com