Preparation method and application of a metal-organic gel perfused organosilicon composite material

A metal-organic and composite material technology, used in biocide-containing paints, antifouling/underwater coatings, coatings, etc. The effect of aging and increased sailing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

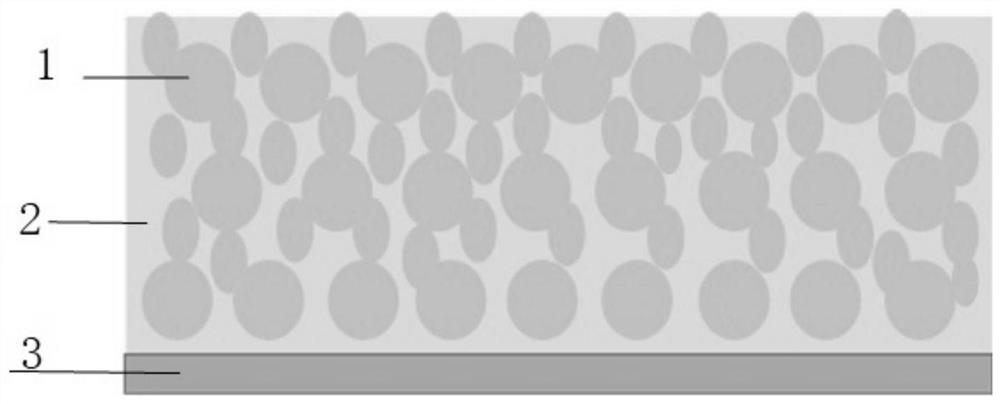

[0031] A method for preparing a metal-organic gel perfused organosilicon composite material, comprising the following steps:

[0032] (1) Preparation of porous PDMS: Take 10 parts of polydimethylsiloxane and 1 part of curing agent, mix them evenly and put them in a refrigerator at 5°C for 24 hours to eliminate the air bubbles to obtain PDMS prepolymer; take 5 parts Spread NaCl in a plastic petri dish, add the defoamed PDMS prepolymer, put it in a vacuum drying oven, pump the vacuum to make the PDMS prepolymer completely penetrate into the NaCl particles, and put it in an oven at 65°C for curing 1h, soak in ultrapure water after solidification, dissolve the salt, and finally dry the porous PDMS.

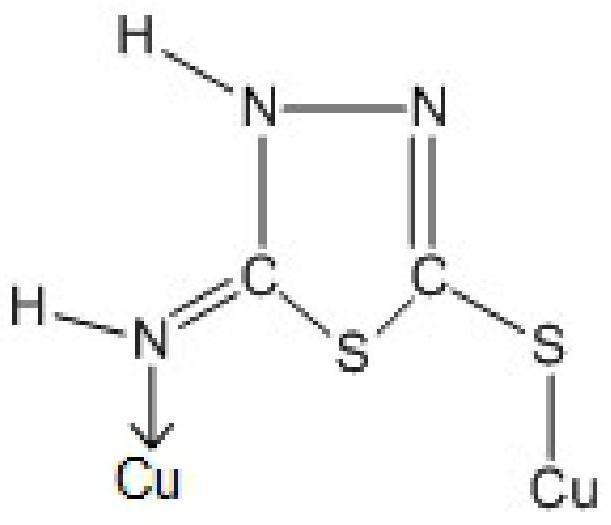

[0033] (2) Preparation of organometallic gel: Weigh 1 mmol 2-amino-5-mercapto-1,3,4-thiadiazole (AMT), dissolve it in 50 mL ultrapure water, add 2 drops of concentrated nitric acid to promote its dissolution , heat at 60°C for 3 hours to completely dissolve AMT; weigh 0.25 mmol CuI, ...

Embodiment 2

[0036] A method for preparing a metal-organic gel perfused organosilicon composite material, comprising the following steps:

[0037] (1) Preparation of porous PDMS: Take 10 parts of polydimethylsiloxane and 1 part of curing agent, mix them evenly and put them in a refrigerator at 5°C for 24 hours to eliminate the air bubbles to obtain PDMS prepolymer; take 5 parts Spread NaCl in a plastic petri dish, add the defoamed PDMS prepolymer, put it in a vacuum drying oven, pump the vacuum to make the PDMS prepolymer completely penetrate into the NaCl particles, and put it in an oven at 65°C for curing 1h, soak in ultrapure water after solidification, dissolve the salt, and finally dry the porous PDMS.

[0038] (2) Preparation of organometallic gel: Weigh 1 mmol 2-amino-5-mercapto-1,3,4-thiadiazole (AMT), dissolve it in 50 mL ultrapure water, add 2 drops of concentrated nitric acid to promote its dissolution , keep warm at 60°C for 3 hours to completely dissolve AMT; weigh 0.25mmol C...

experiment example 1

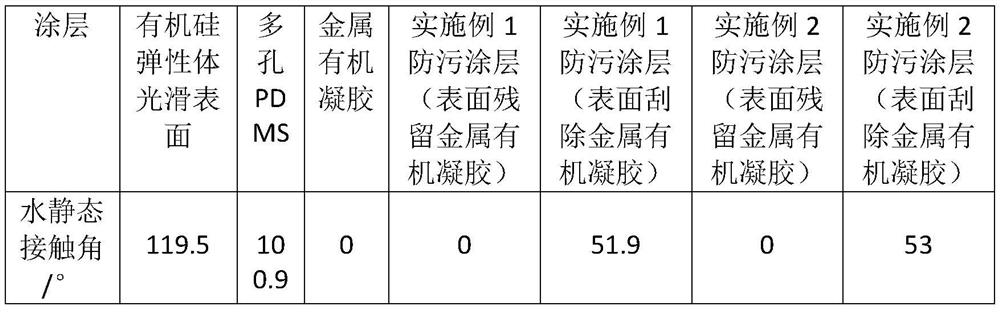

[0041] The static contact angles of the silicone elastomer smooth surface, the porous PDMS prepared in Example 1 or 2, and the antifouling coating surface prepared in Example 1 and 2 were measured with a static contact angle measuring instrument. See Table 1 for the results.

[0042] Table 1 The water static contact angle of each coating

[0043]

[0044] It can be seen from Table 1 that the smooth surface of silicone elastomer and porous PDMS itself are non-superhydrophobic surfaces, which are not conducive to inhibiting the adhesion of fouling organisms. Highly hydrophilic metal-organic gels are beneficial to inhibit the attachment of fouling organisms. The protective coating obtained in the embodiment with metal organic gel remaining on the surface has a contact angle of 0, and when the metal organic gel on the surface is scraped off, the contact angle is about 52 degrees, and the more porous PDMS has reduced by more than 50%. It shows that when the metal organic gel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com