Polyethylene composite antibacterial coating and preparation method thereof

A composite antibacterial and polyethylene technology, which is applied in coatings, antifouling/underwater coatings, devices for coating liquids on surfaces, etc., can solve problems such as shedding, pollution, and loss of antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

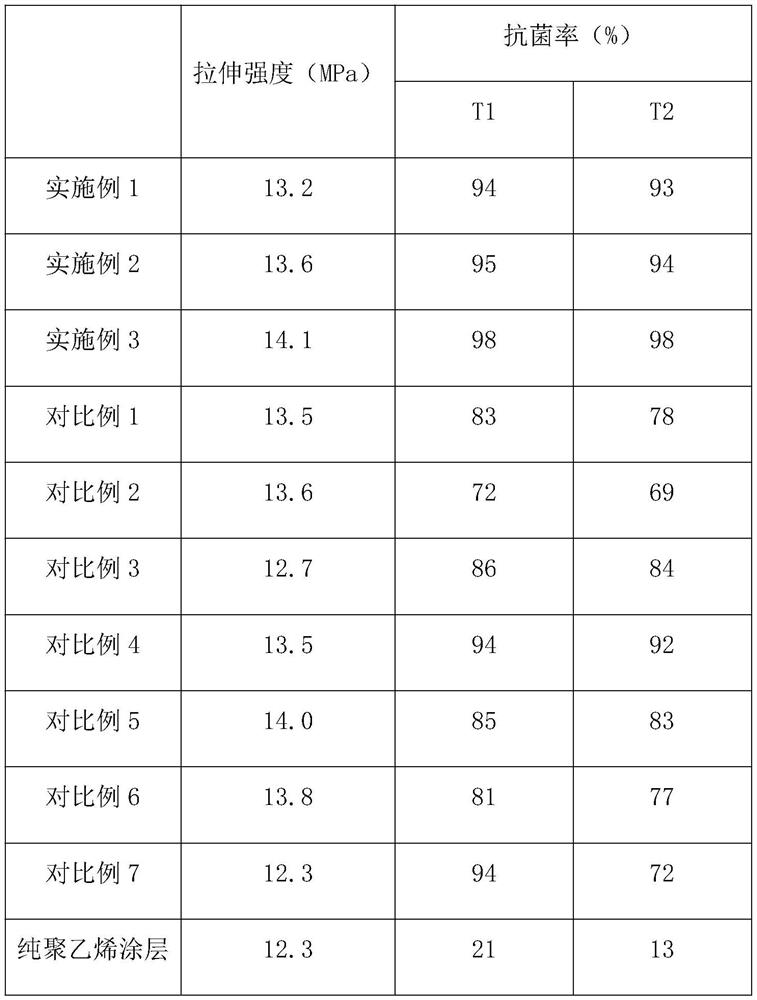

Examples

Embodiment 1

[0037] (1) Preparation of coating:

[0038] Take 16 parts of polyethylene glycol and 21 parts of acrylic acid, add deionized water, and stir at room temperature for 10 minutes to prepare a mixed solution;

[0039] Dissolve 100 parts of polyethylene in N,N-dimethylformamide, add N,N'-methylenebisacrylamide, stir at 70°C for 10 minutes, insert electrodes, and electrify for 5 minutes, where the discharge voltage is 600V and the current 60mV, then react at a constant temperature of 70°C for 4h, take the reaction product and wash and dry it to obtain modified polyethylene;

[0040] Take modified polyethylene and 8 parts of chloroether resin, add xylene and stir thoroughly to prepare the coating;

[0041] (2) Preparation of surface treatment agent:

[0042] (a) Preparation of modified zinc oxide nanocolumns:

[0043] Take the glass sheet for full cleaning and drying as the substrate;

[0044] Blend polyvinyl alcohol and zinc acetate, add deionized water, heat to 80°C and stir fo...

Embodiment 2

[0057] (1) Preparation of coating:

[0058] Take 18 parts of polyethylene glycol and 24 parts of acrylic acid, add deionized water, and stir at room temperature for 15 minutes to prepare a mixed solution;

[0059] Dissolve 100 parts of polyethylene in N,N-dimethylformamide, add N,N'-methylenebisacrylamide, stir at 75°C for 15 minutes, insert electrodes, and electrify for 7 minutes, in which the discharge voltage is 635V and the current 66mV, then react at a constant temperature of 75°C for 4.5h, take the reaction product and wash and dry it to obtain modified polyethylene;

[0060] Take modified polyethylene and 11 parts of chloroether resin, add xylene and stir thoroughly to prepare the coating;

[0061] (2) Preparation of surface treatment agent:

[0062] (a) Preparation of modified zinc oxide nanocolumns:

[0063] Take the glass sheet for full cleaning and drying as the substrate;

[0064] Blend polyvinyl alcohol and zinc acetate, add deionized water, heat to 87°C and s...

Embodiment 3

[0077] (1) Preparation of coating:

[0078] Take 20 parts of polyethylene glycol and 28 parts of acrylic acid, add deionized water, and stir at room temperature for 20 minutes to prepare a mixed solution;

[0079] Dissolve 100 parts of polyethylene in N,N-dimethylformamide, add N,N'-methylenebisacrylamide, stir at 80°C for 20 minutes, insert electrodes, and electrify for 10 minutes, where the discharge voltage is 670V and the current 72mV, then reacted at a constant temperature of 80°C for 5h, and the reaction product was washed and dried to obtain modified polyethylene;

[0080] Take modified polyethylene and 15 parts of chloroether resin, add xylene and stir thoroughly to prepare the coating;

[0081] (2) Preparation of surface treatment agent:

[0082] (a) Preparation of modified zinc oxide nanocolumns:

[0083] Take the glass sheet for full cleaning and drying as the substrate;

[0084] Blend polyvinyl alcohol and zinc acetate, add deionized water, heat to 95°C and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com