A supramolecular oil displacing agent and its preparation method

An oil displacing agent and supramolecular technology, applied in the field of supramolecular oil displacing agent and its preparation, can solve the problems of weak shear thickening ability, poor water solubility, poor surface properties, etc., so as to improve the solubilization ability and reduce the seepage resistance. , the effect of improving temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

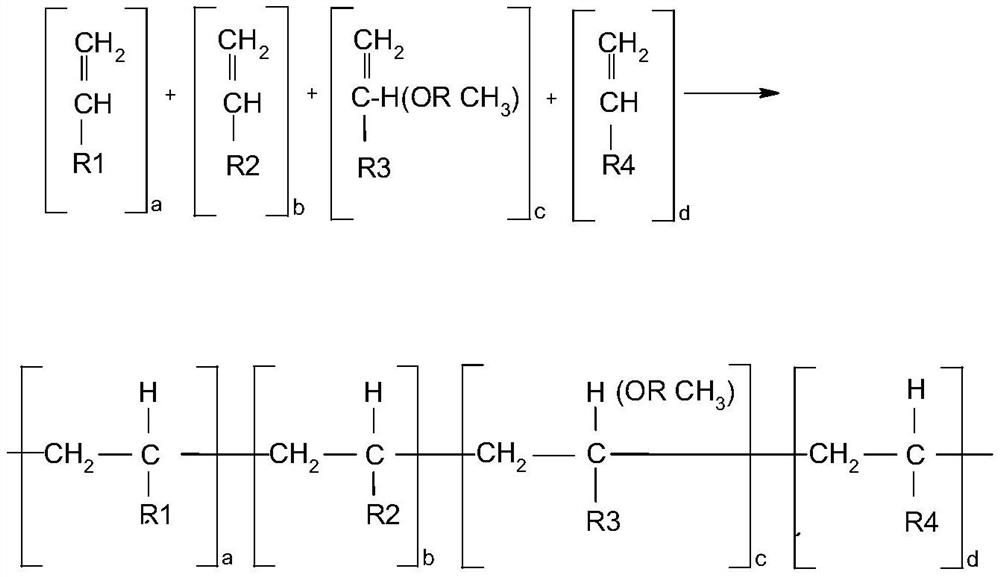

Method used

Image

Examples

Embodiment 1

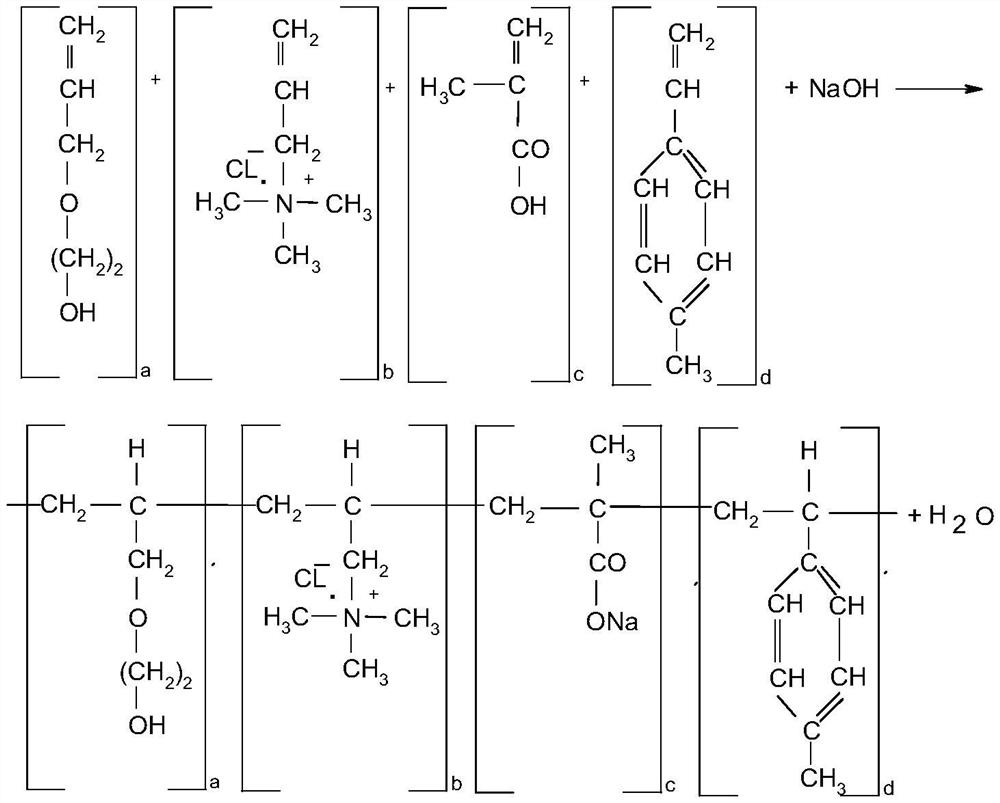

[0032]Add an appropriate amount of reactants ethylene glycol monoallyl ether (AEO), trimethylallyl ammonium chloride (TMAAC), formaldehyde into a four-necked flask equipped with a stirrer, a constant pressure dropping funnel, a thermometer, and a condenser. Acrylic acid (MAA), p-methylstyrene (PMS) and phase transfer agent sodium dodecylbenzenesulfonate and solvent deionized water, wherein the molar ratio of reactants is n (ethylene glycol monoallyl ether) : n (trimethylallyl ammonium chloride): n (methacrylic acid): n (p-methylstyrene) = 3: 1: 6: 1; phase transfer agent sodium dodecylbenzene sulfonate and The mass ratio of reactants is w (sodium dodecylbenzenesulfonate): w (reactant) = 0.02: 1, and the mass ratio of solvent deionized water to reactant and phase transfer agent is w (deionized water): w( Reactant + phase transfer agent) = 1:1, first add 70% molar fraction of deionized water into the four-necked flask, and stir evenly. The mass of initiator ammonium persulfate ...

Embodiment 2

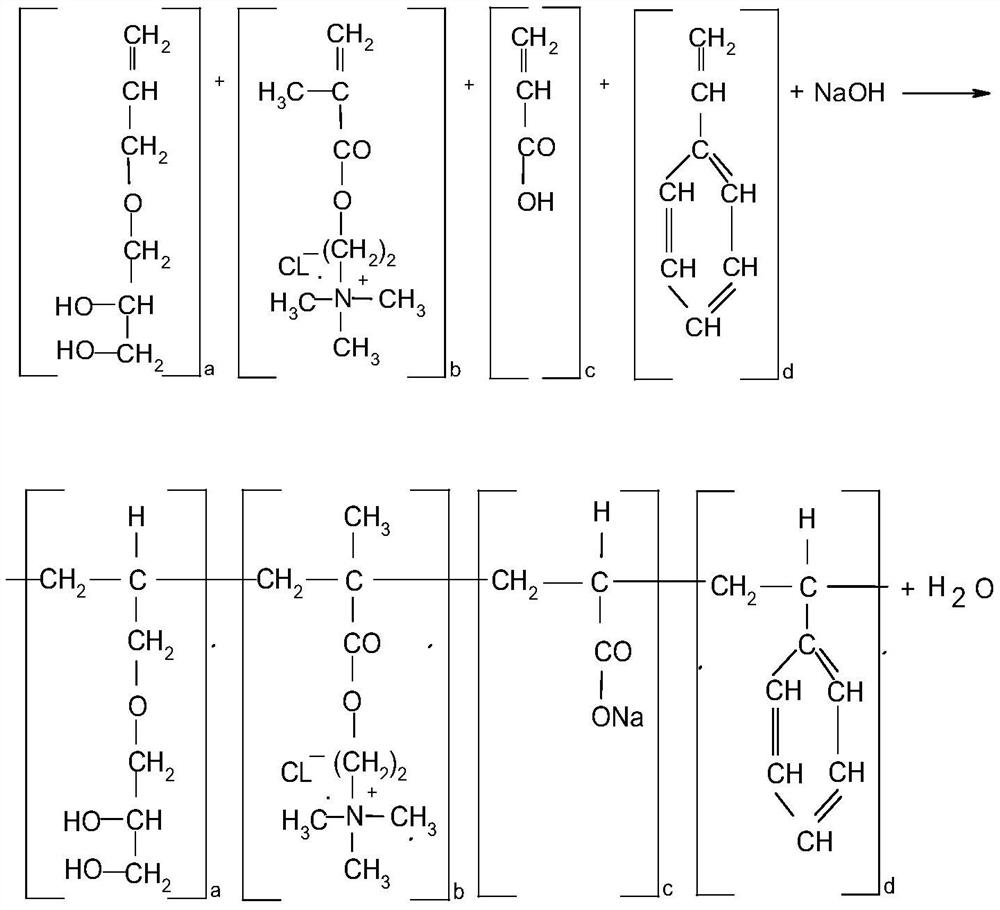

[0037] In a four-neck flask equipped with a stirrer, a constant pressure dropping funnel, a thermometer, and a condenser, add an appropriate amount of reactants glycerol allyl ether (AG), methacryloyloxyethyltrimethylammonium chloride (DMC), Acrylic acid (AA), styrene (St) and phase transfer agent nonylphenol polyoxyethylene ether and solvent deionized water, wherein the molar ratio of reactants is n (glycerin allyl ether): n (methacryloxy Ethyltrimethylammonium chloride): n (acrylic acid): n (styrene) = 4: 2: 8: 1; phase transfer agent nonylphenol polyoxyethylene ether-10 (OP-10) and reactant quality The ratio is w(nonylphenol polyoxyethylene ether-10):w(reactant)=0.01:1, the mass ratio of solvent deionized water to reactant and phase transfer agent is w(deionized water):w(reactant + phase transfer agent) = 1.5:1, first add 70% mole fraction of deionized water into the four-necked flask, and stir evenly. The mass of initiator sodium persulfate and reactant is w (sodium persu...

Embodiment 3

[0042] Add an appropriate amount of reactants allyl polyoxyethylene methyl ether (HPEG) (n=60), dimethyl diallyl chloride into a four-necked flask equipped with a stirrer, a constant pressure dropping funnel, a thermometer, and a condenser. Ammonium chloride (DMDAAC), acrylic acid (AA), styrene (St) and phase transfer agent nonylphenol polyoxyethylene ether and solvent deionized water, wherein the molar ratio of the reactants is n (allyl polyoxyethylene methyl Ether (n=60)): n (dimethyl diallyl ammonium chloride): n (acrylic acid): n (styrene) = 6: 3: 12: 1; phase transfer agent alkylphenol polyoxyethylene The mass ratio of ether-10 (OP-10) to reactant is w(alkylphenol polyoxyethylene ether-10):w(reactant)=0.02:1, the mass ratio of solvent deionized water to reactant and phase transfer agent It is w (deionized water): w (reactant + phase transfer agent) = 1.5:1, first add 70% mole fraction of deionized water into the four-necked flask, and stir evenly. Initiator ammonium pers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com