A kind of film for controlling droplet shape and its preparation method and application

A technology for controlling liquid and thin films, which is applied in the process of producing decorative surface effects, the coupling of optical waveguides, and the manufacture of microstructure devices. It can solve the problems of easy overflow of liquid at the boundary and poor control of boundary overflow, and achieve Prevent boundary overflow, improve robustness, and suppress the effects of diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

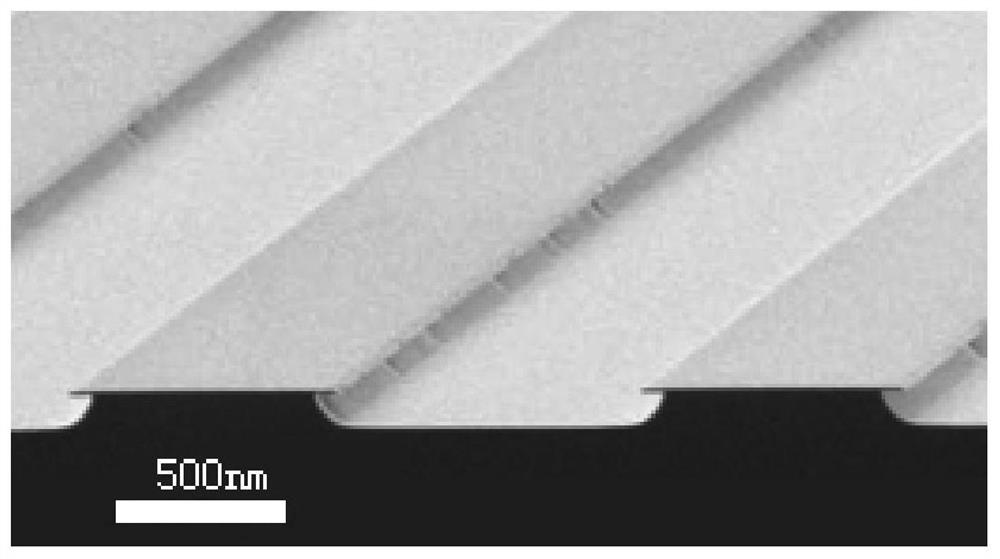

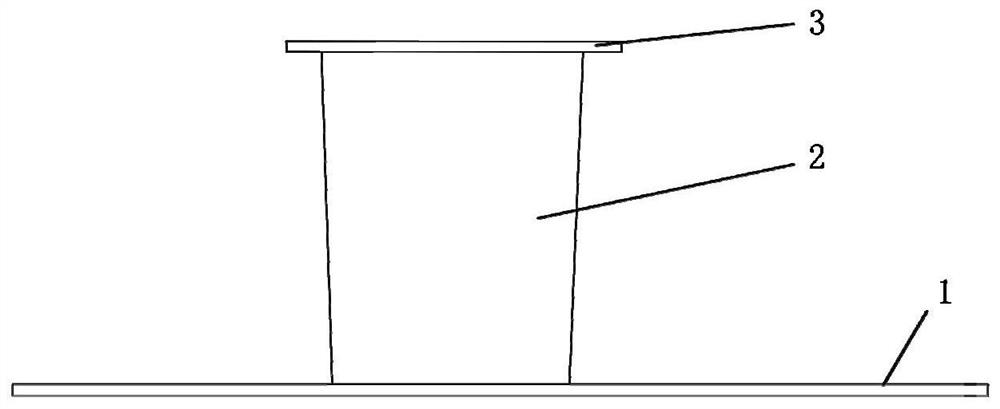

[0051] Step 1: Deposit a layer of 100nm titanium metal layer 2 on the glass substrate 1 by magnetron sputtering deposition process.

[0052] Step 2: Writing a rectangular array pattern on the 100nm titanium metal layer 2 by laser direct writing technology to obtain a patterned titanium metal layer. Among them, the writing parameters of the laser direct writing technology are: laser power 6mW; laser pulse width 1ms.

[0053] Step 3: immerse the obtained patterned thin film in a dilute hydrogen fluoride solution with a mass fraction of 6% for 100 min to obtain a thin film with a rectangular array pattern for controlling the droplet shape.

[0054] Step 4: Water droplets are dropped onto the film for controlling the droplet shape in a rectangular array pattern, and the droplets can spread along the rectangular pattern and be pinned to the sharp edges of the rectangular pattern.

Embodiment 2

[0056] Step 1: Deposit a layer of 20nm titanium metal layer 2 on the glass substrate 1 by magnetron sputtering deposition process.

[0057] Step 2: Write the square array pattern on the 20nm titanium metal layer 2 by laser direct writing technology to obtain a patterned titanium metal layer. Among them, the writing parameters of the laser direct writing technology are: laser power 6mW; laser pulse width 1ms.

[0058] Step 3: immerse the obtained patterned titanium metal layer in a dilute hydrogen fluoride solution with a mass fraction of 5% for 60 minutes to obtain a thin film with a rectangular array pattern for controlling the droplet shape.

[0059] Step 4: Drop the water droplet onto the thin film for controlling the shape of the droplet in a rectangular array pattern. The droplet can spread along the rectangular pattern and be pinned on the sharp edge of the rectangular pattern. The droplet does not collapse within 1 hour.

Embodiment 3

[0061] Step 1: Deposit a layer of 200nm titanium metal layer 2 on the glass substrate 1 by magnetron sputtering deposition process.

[0062] Step 2: Writing a rectangular array pattern on the 200nm titanium metal layer 2 by laser direct writing technology to obtain a patterned titanium metal layer. Among them, the writing parameters of the laser direct writing technology are: laser power 6mW; laser pulse width 1ms.

[0063] Step 3: immerse the obtained patterned titanium metal layer in a diluted hydrogen fluoride solution with a mass fraction of 8% for 150 minutes to obtain a rectangular pattern array with sharp edges.

[0064] Step 4: Drop the water droplet onto the thin film for controlling the shape of the droplet in a rectangular array pattern. The droplet can spread along the rectangular pattern and be pinned on the sharp edge of the rectangular pattern. The droplet does not collapse within 1 hour.

[0065] The invention solves the problem that the droplet is not robust ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com