A protective foam wrapping and fixing device for the exterior of an electrolytic copper foil roll

A technology of electrolytic copper foil and fixing device, which is applied in the field of electrolytic copper foil, can solve the problems of heavy weight of copper foil roll, deformation of copper foil roll, low wrapping efficiency, etc., and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] After the electrolytic copper foil roll is made into a roll, the flatness of the surface of the copper foil affects the performance of the electrolytic copper foil, and the copper foil roll cannot avoid collision and extrusion during transportation, which makes the copper foil roll deformed. Therefore, the present invention sets a A protective foam covering and fixing device for the exterior of an electrolytic copper foil roll, through which a layer of protective foam can be wrapped on the surface of the electrolytic copper foil roll to protect the electrolytic copper foil roll and prevent the electrolytic copper foil roll from being squeezed and deformed .

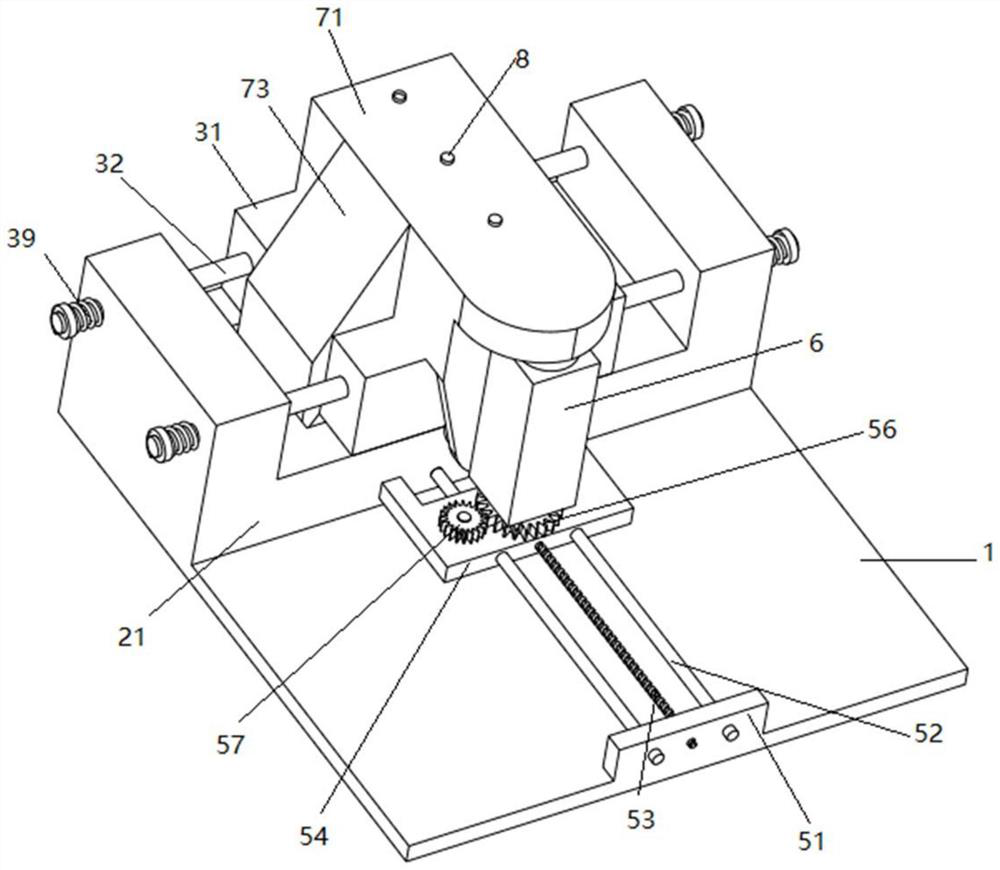

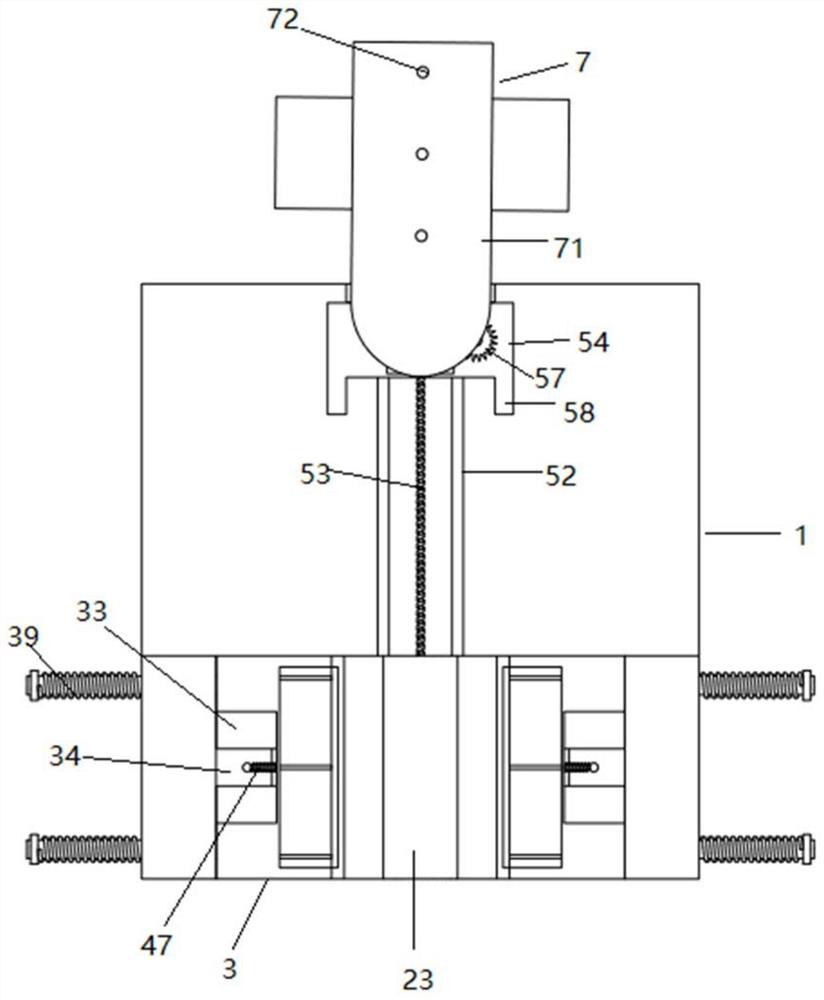

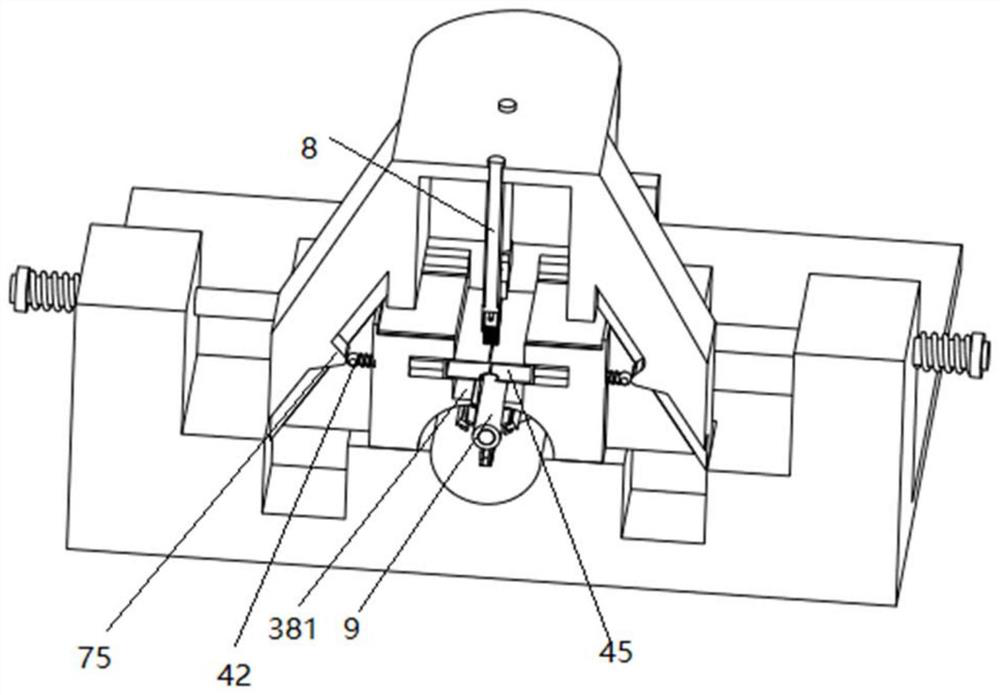

[0033] Comes with instructions Figure 1-4 It can be seen that the electrolytic copper foil roll externally covered with protective foam and fixing device disclosed in the present invention includes a support base 1, one side of the surface of the support base 1 is integrally connected and fixed with a positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com