Graphite type carbon nitride composite photocatalytic material containing oxygen vacancy bismuth tungstate/oxygen-enriched structure as well as preparation method and application of graphite type carbon nitride composite photocatalytic material

A graphite-type carbon nitride and composite photocatalysis technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the limitations of rapid recombination and light harvesting ability, narrow band gap, redox performance Weaken and other problems, achieve excellent photocatalytic performance, avoid recombination, and improve the effect of light harvesting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A graphite carbon nitride composite photocatalytic material containing oxygen vacancies bismuth tungstate / oxygen-rich structure of the present invention is composed of bismuth tungstate containing oxygen vacancies and graphite carbon nitride with oxygen-rich structures. The composite material is three-dimensional structure, the mass ratio of bismuth tungstate containing oxygen vacancies and graphitic carbon nitride with oxygen-rich structure in the composite photocatalytic material is 5:1.

[0049] A preparation method of the above-mentioned oxygen-vacancy bismuth tungstate / oxygen-rich structure graphite-type carbon nitride composite photocatalytic material of the present embodiment, comprising the following steps:

[0050] S1. Mix 50mmol of dicyandiamide and 0.5mmol of ammonium tungstate evenly, put them into a covered crucible with a diameter of 50mm, and calcinate at 500°C for 4 hours to obtain graphite-type carbon nitride OCN with an oxygen-rich structure.

[0051] ...

Embodiment 2

[0054] A graphite-type carbon nitride composite photocatalytic material containing oxygen vacancies bismuth tungstate / oxygen-rich structure of the present invention is basically the same as the composite photocatalytic material in Example 1, the only difference being that the composite photocatalytic material contains oxygen The mass ratio of the vacant bismuth tungstate and the graphite-type carbon nitride of the oxygen-rich structure is 4:1.

[0055] A preparation method of the graphite-type carbon nitride composite photocatalyst material with oxygen-vacancy bismuth tungstate / oxygen-rich structure in this embodiment is basically the same as the preparation method in Example 1, the only difference being: the rich The graphite carbon nitride with oxygen structure is 0.475g, and the graphite carbon nitride composite photocatalyst material 4BWO-OV / OCN with oxygen vacancy bismuth tungstate / oxygen-rich structure is obtained.

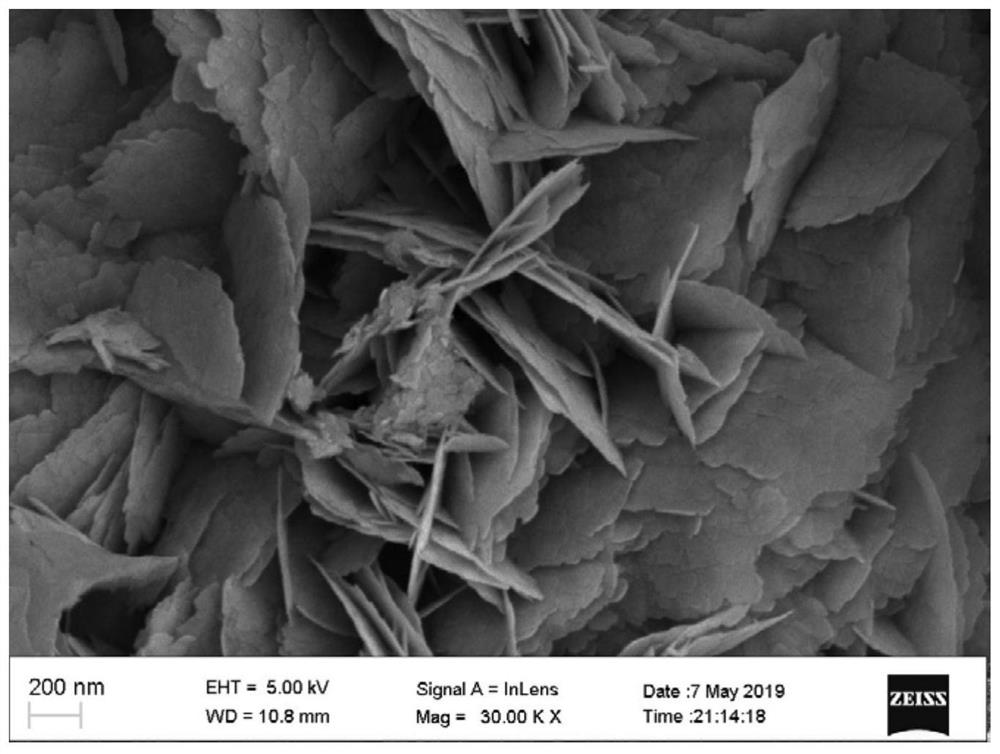

[0056] figure 1 It is the SEM picture of 4BWO-OV / OCN ...

Embodiment 3

[0061] A graphite-type carbon nitride composite photocatalytic material containing oxygen vacancies bismuth tungstate / oxygen-rich structure of the present invention is basically the same as the composite photocatalytic material in Example 1, the only difference being that the composite photocatalytic material contains oxygen The mass ratio of the vacant bismuth tungstate and the graphite-type carbon nitride of the oxygen-rich structure is 3:1.

[0062]A preparation method of the graphite-type carbon nitride composite photocatalyst material with oxygen-vacancy bismuth tungstate / oxygen-rich structure in this embodiment is basically the same as the preparation method in Example 1, the only difference being: the rich The graphite carbon nitride with oxygen structure is 0.63g, and the graphite carbon nitride composite photocatalyst material 3BWO-OV / OCN with oxygen vacancy bismuth tungstate / oxygen-rich structure is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com