Drainage and stirring device for concentrated sulfuric acid dilution treatment

A stirring device and dilution treatment technology, which is applied to mixers with rotary stirring devices, accessories of mixers, transportation and packaging, etc., can solve the problems of waste of heat resources, reduce processing efficiency, etc. Increase the effect of the flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

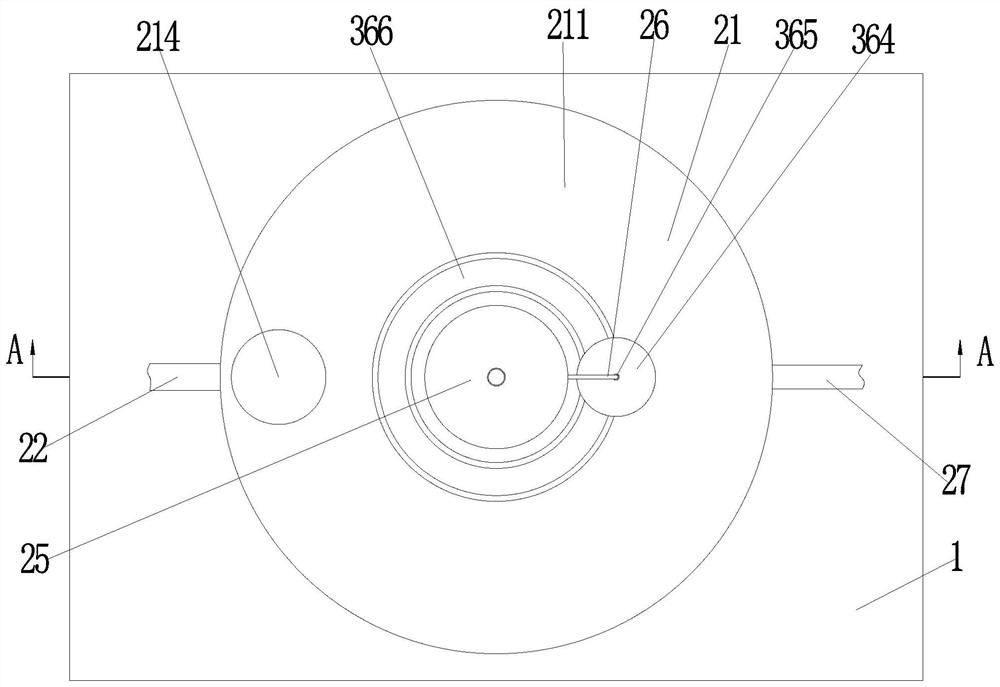

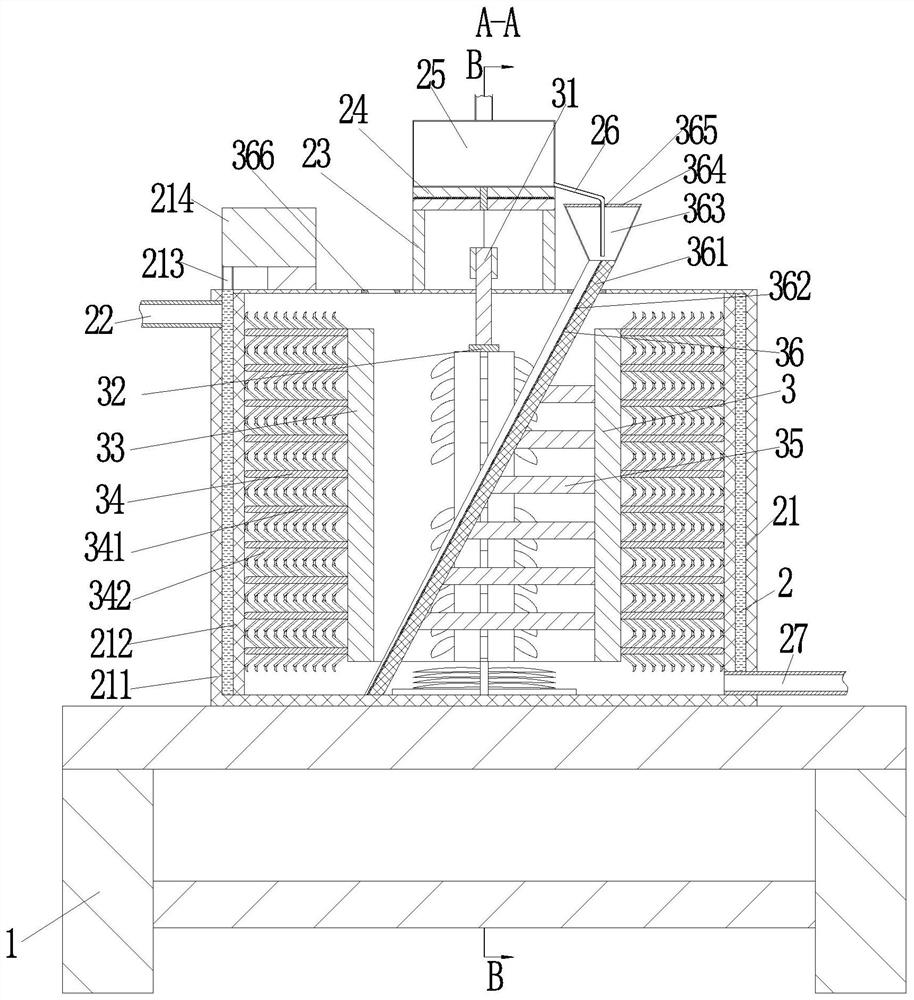

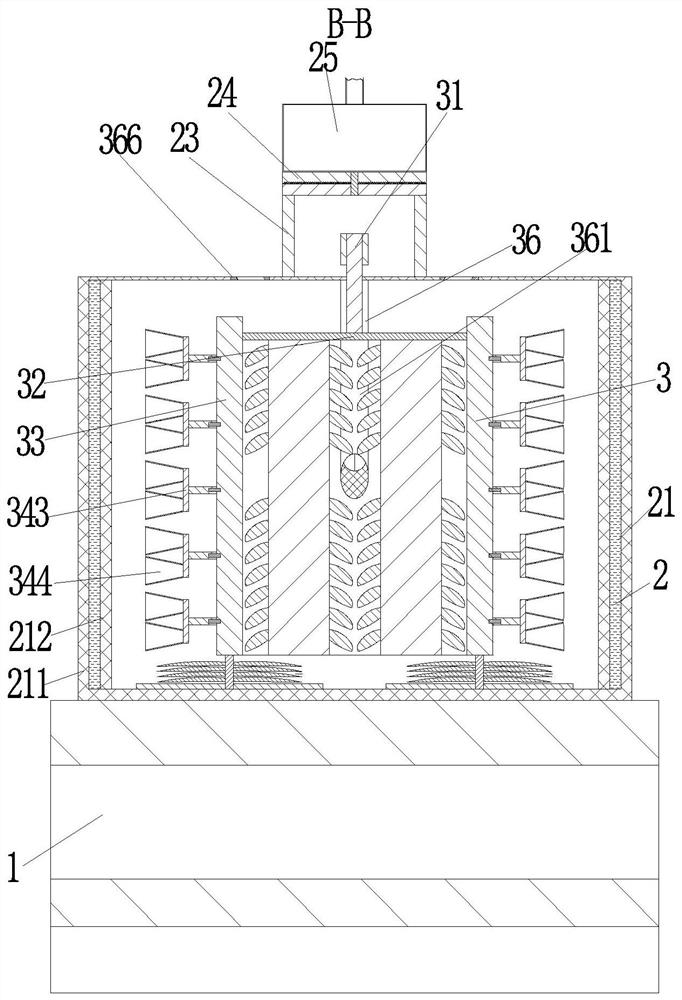

[0032] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 6 , to further elaborate the present invention.

[0033] A concentrated sulfuric acid dilution treatment drainage stirring device, including a workbench 1, a holding device 2 and a stirring device 3, the upper end of the workbench 1 is fixedly equipped with a holding device 2, and the upper end of the holding device 2 is equipped with a stirring device 3; wherein :

[0034] The holding device 2 includes a holding tank 21, a water delivery pipe 22, a support frame 23, a sliding plate 24, a sulfuric acid box 25, an acid delivery pipe 26 and an output pipe 27. The upper end of the workbench 1 is fixedly equipped with a holding tank 21. The upper end of the left side of the tank 21 is provided with a water pipe 22, the upper end of the storage tank 21 is fixedly equipped with a support frame 23, the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com