Continuous dehydration esterification reaction device as well as continuous esterification reaction method

A technology of esterification reaction and reaction kettle, which is applied in the field of esterification reaction, can solve the problems of increasing energy consumption and difficulty in product separation, reducing production efficiency, and low reaction efficiency, so as to maintain controllability, improve utilization rate, and improve The effect of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

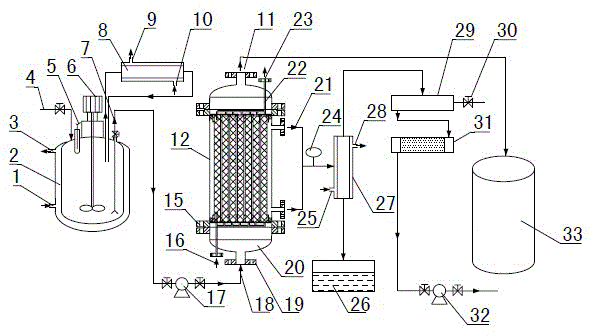

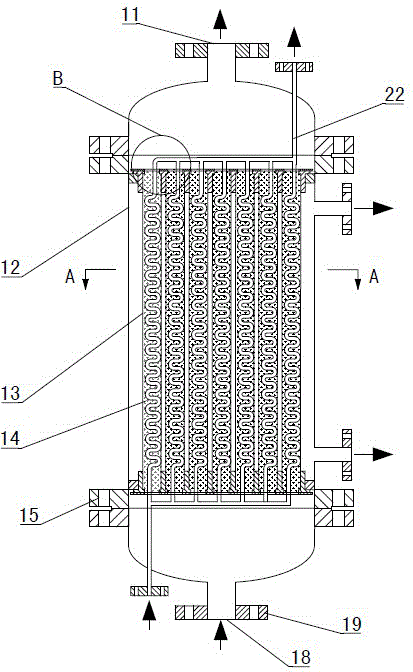

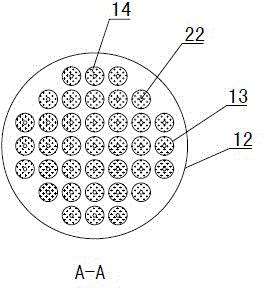

[0029] Figure 1~4 It is the best embodiment of the continuous dehydration esterification reaction device and continuous esterification reaction method of the present invention. Figure 1~4 The present invention will be further explained.

[0030] Reference attached figure 1 :Continuous dehydration and esterification reaction device, including reactor 2, membrane reactor, vacuum pump 32 and storage tank 33. The reaction materials are added to reactor 2 after being mixed and heated, and then sent into membrane reactor by peristaltic pump 17. In the membrane reactor, the water produced by the reaction in the membrane reactor is pumped out by the vacuum pump 32, and the reaction product is stored in the storage tank 33 through the outlet 11 of the membrane reactor. The reaction material enters directly after being fully reacted in the membrane reactor. The storage tank 33 continuously pumps out the water produced by the reaction through the vacuum pump 32 to promote the reaction to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com