Preparation method of wide-temperature-range electrolyte for supercapacitor

A supercapacitor, wide temperature range technology, used in the manufacture of hybrid capacitor electrolytes, hybrid/electric double layer capacitors, etc., can solve the problems of high price, narrow voltage window, flammability, etc., to improve the use effect and service life, The effect of wide electrochemical stability window and wide operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

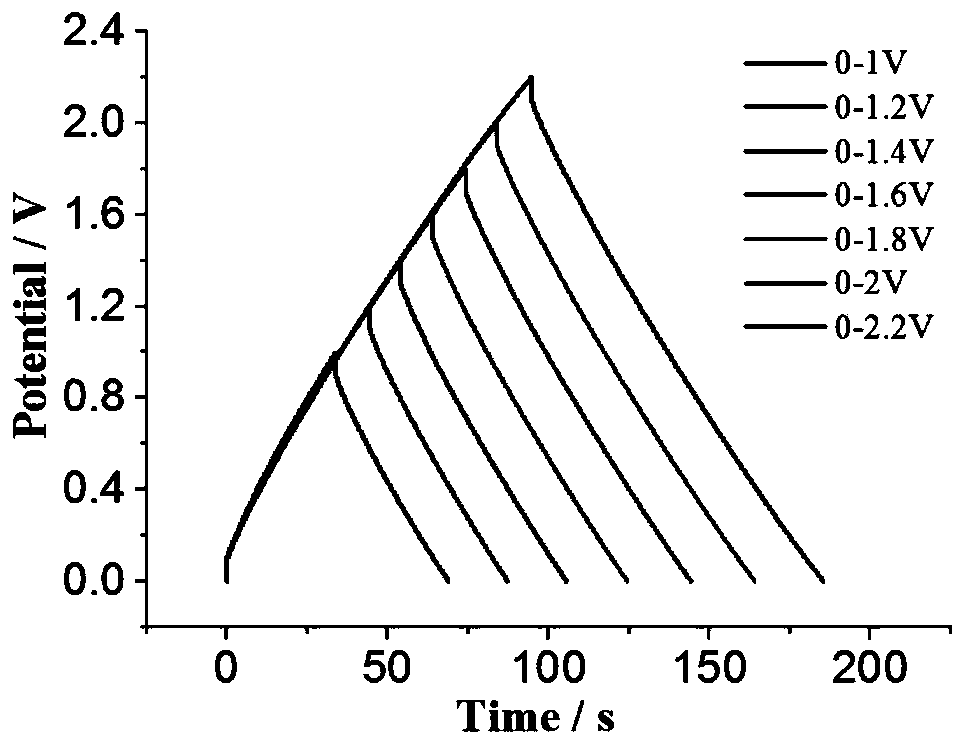

[0023] Example 1: A preparation method of wide temperature range electrolyte for supercapacitor

[0024] An electrolytic solution with a wide temperature range for a supercapacitor and a preparation method thereof, characterized in that it includes the following technical steps.

[0025] (1) material preparation

[0026] An electrolytic solution with a wide temperature range for a supercapacitor is composed of an electrolyte and a solvent.

[0027] The electrolyte is one or more combinations of tetramethylammonium bromide, tetraethylammonium bromide, tetrapropylammonium bromide, tetrabutylammonium bromide and the like. The tetramethylammonium bromide, tetraethylammonium bromide, tetrapropylammonium bromide and tetrabutylammonium bromide are of reagent grade with a purity of ≥98.0%.

[0028] The solvent is ethylene glycol. The ethylene glycol is reagent grade with a purity of ≥98.0%.

[0029] (2) deployment

[0030] A certain mass of solute is evenly added to ethylene glyc...

Embodiment 2

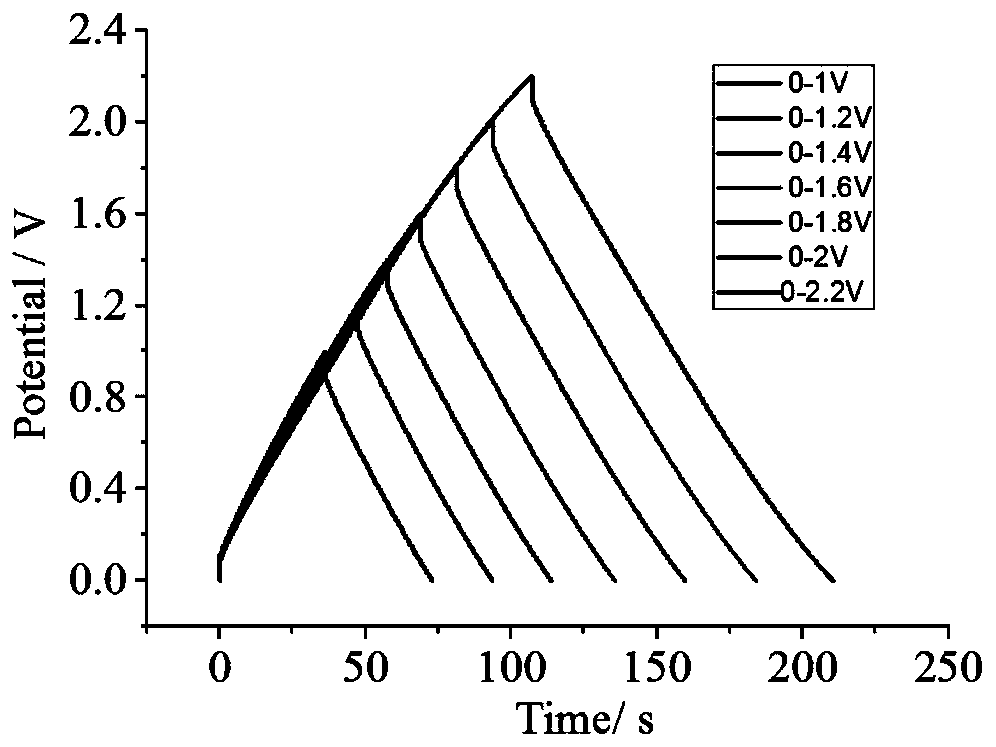

[0041] Embodiment 2: A kind of preparation method of wide temperature zone electrolyte solution for supercapacitor

[0042] The difference from Example 1 is:

[0043] Solute: tetraethylammonium bromide, the concentration of the electrolyte is 4.5 mol / L; solvent: ethylene glycol; the test temperature is 0°C.

Embodiment 3

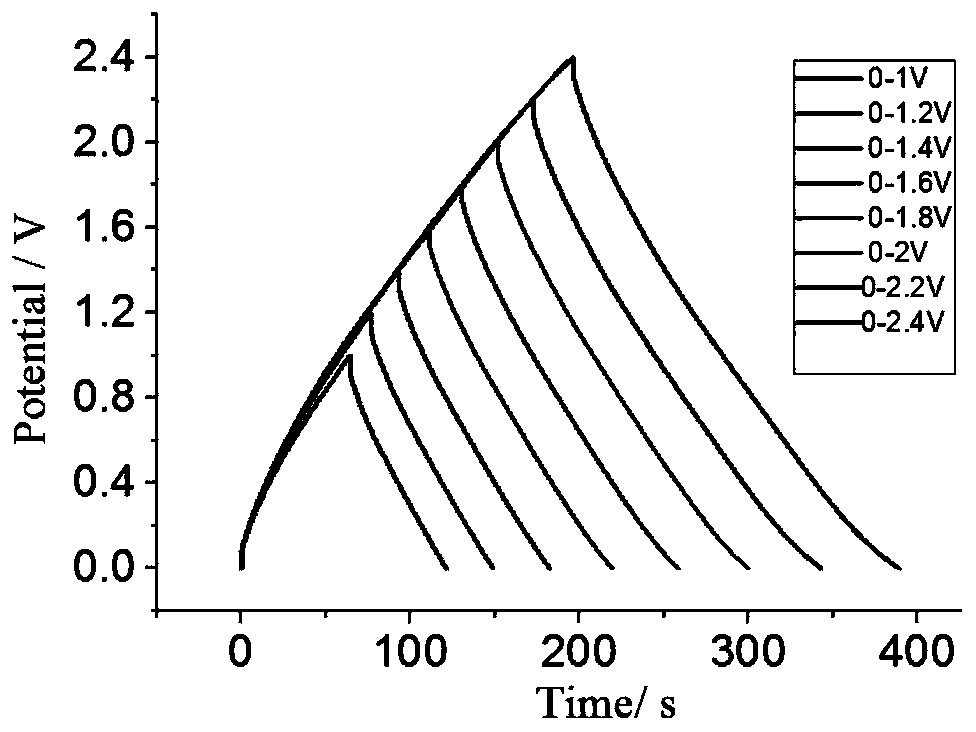

[0044] Embodiment 3: A kind of preparation method of wide temperature zone electrolyte solution for supercapacitor

[0045] An electrolytic solution with a wide temperature range for a supercapacitor and a preparation method thereof are prepared from the following raw materials.

[0046] The difference from Example 1 is:

[0047] Solute: tetrapropylammonium bromide, the concentration of the electrolyte is 6.5 mol / L; solvent: ethylene glycol; the test temperature is 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com