Coring steel wire rope cleaning device for rope coring drilling tool

A technology for core drilling tools and cleaning devices, applied in the direction of extracting undisturbed core devices, cleaning methods using gas flow, cleaning methods and appliances, etc., can solve the problem of polluting drilling platform operators and operating equipment, reducing the service life of steel wire ropes, and splashing And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

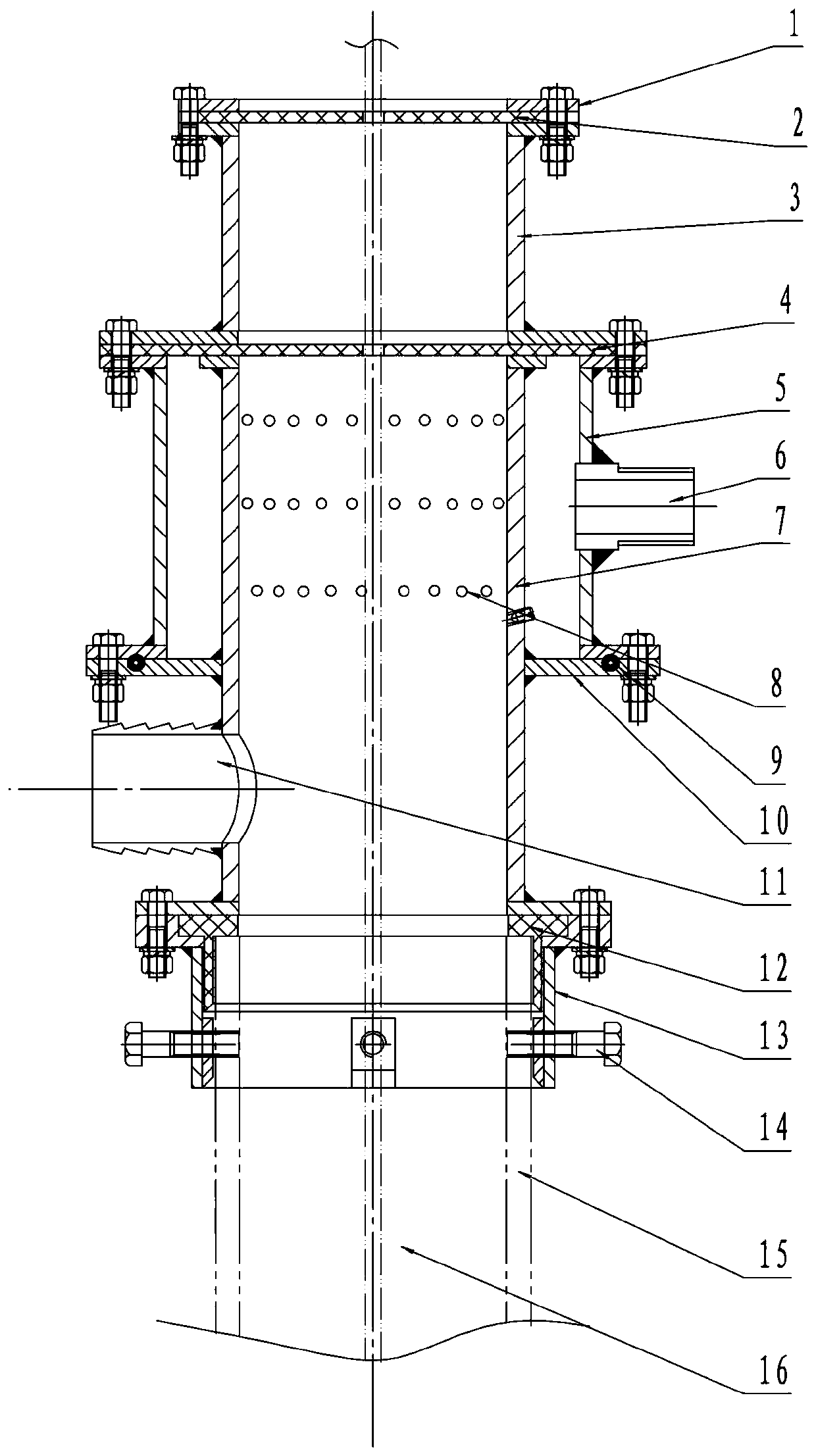

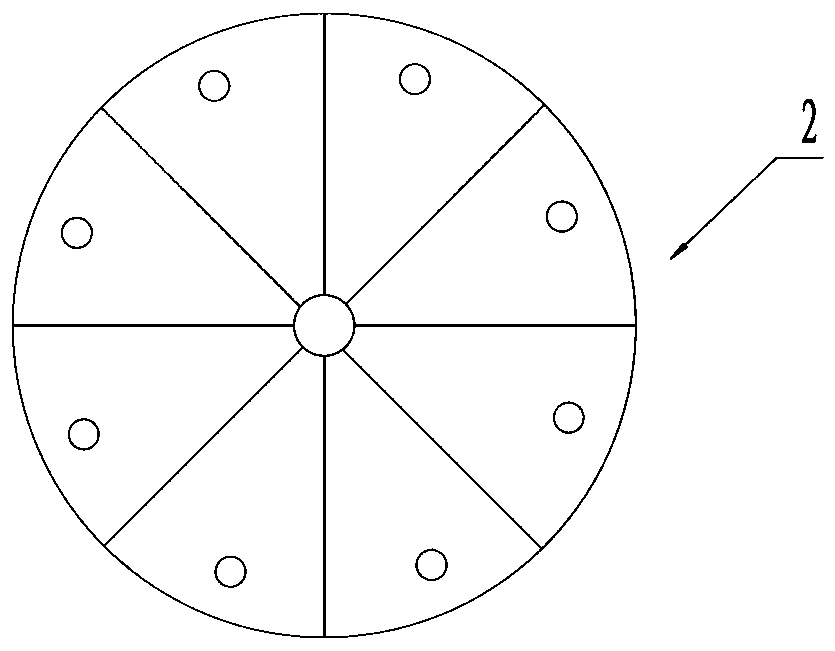

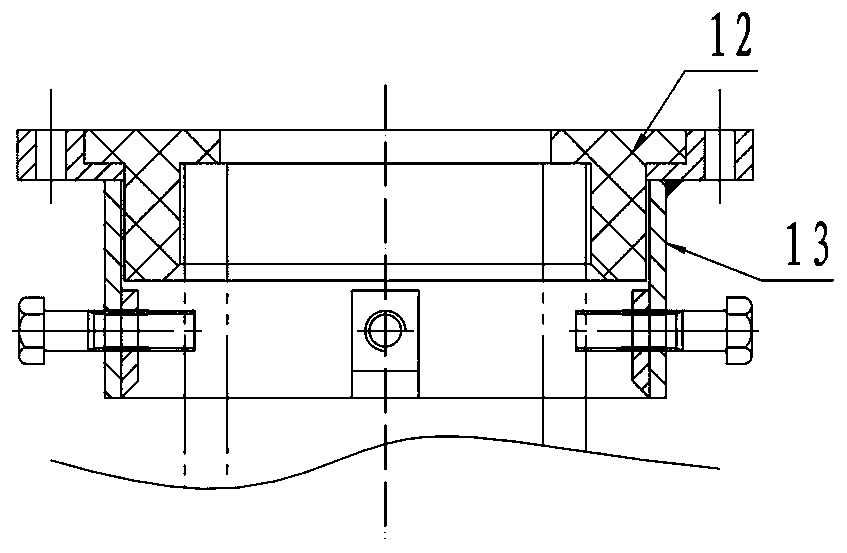

[0018] see figure 1 , figure 2 , the present invention is installed on the top of drill pipe 15, and its composition comprises the purge chamber 7 that cleans steel wire rope 16, the high-pressure air chamber 5 that provides high-pressure gas for purge chamber, the upper part of purge chamber is provided with buffer chamber, and the bottom part of purge chamber is provided with There is a drill pipe installation pressure sleeve 13 for fixing the drill pipe. The purging chamber is cylindrical, and the outer wall of the upper part of the purging chamber is provided with nozzles 8 for ejecting high-pressure gas in the circumferential direction. There are at least two rows of nozzles, and 12-16 nozzles are evenly distributed in each row. The purge chamber is provided with a mud overflow port 11, which is located at the lower part of the high-pressure air chamber, and the mud overflow port is used to scrape and discharge the mud adhered to the inner pipe when the inner pipe is ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com