Fluorescent carbon quantum dots with scale inhibition performance as well as preparation method and application thereof

A technology of carbon quantum dots and fluorescence, which is applied in the field of industrial water treatment chemicals, can solve the problems of single scale inhibition performance, narrow application range, and use restrictions, and achieve the effect of simple and fast synthesis method and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing fluorescent carbon quantum dots with scale inhibition performance includes the following steps:

[0035] Weigh 2.50g polyacrylic acid (PAA) (50%, Tech), dissolve it in 46.25g deionized water, add 1.25g ethylenediamine; mix the raw materials uniformly, and move to a closed polytetrafluoroethylene high-pressure reactor, Place in an oven, set the temperature to 180°C, react for 5 hours, after the reaction is completed, cool to room temperature naturally to obtain a brown reaction liquid; filter the reaction liquid, and the obtained filtrate is a fluorescent carbon quantum dot solution with scale inhibition performance.

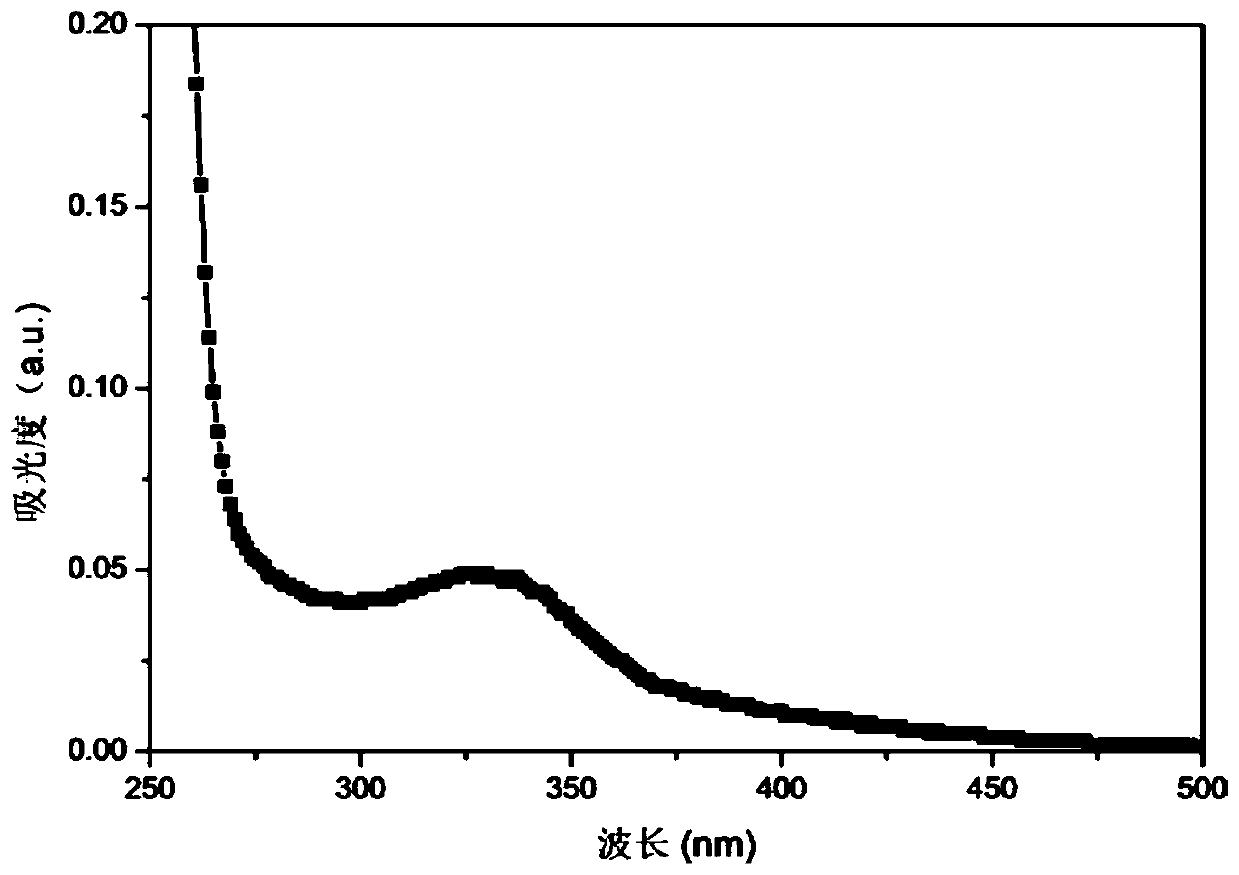

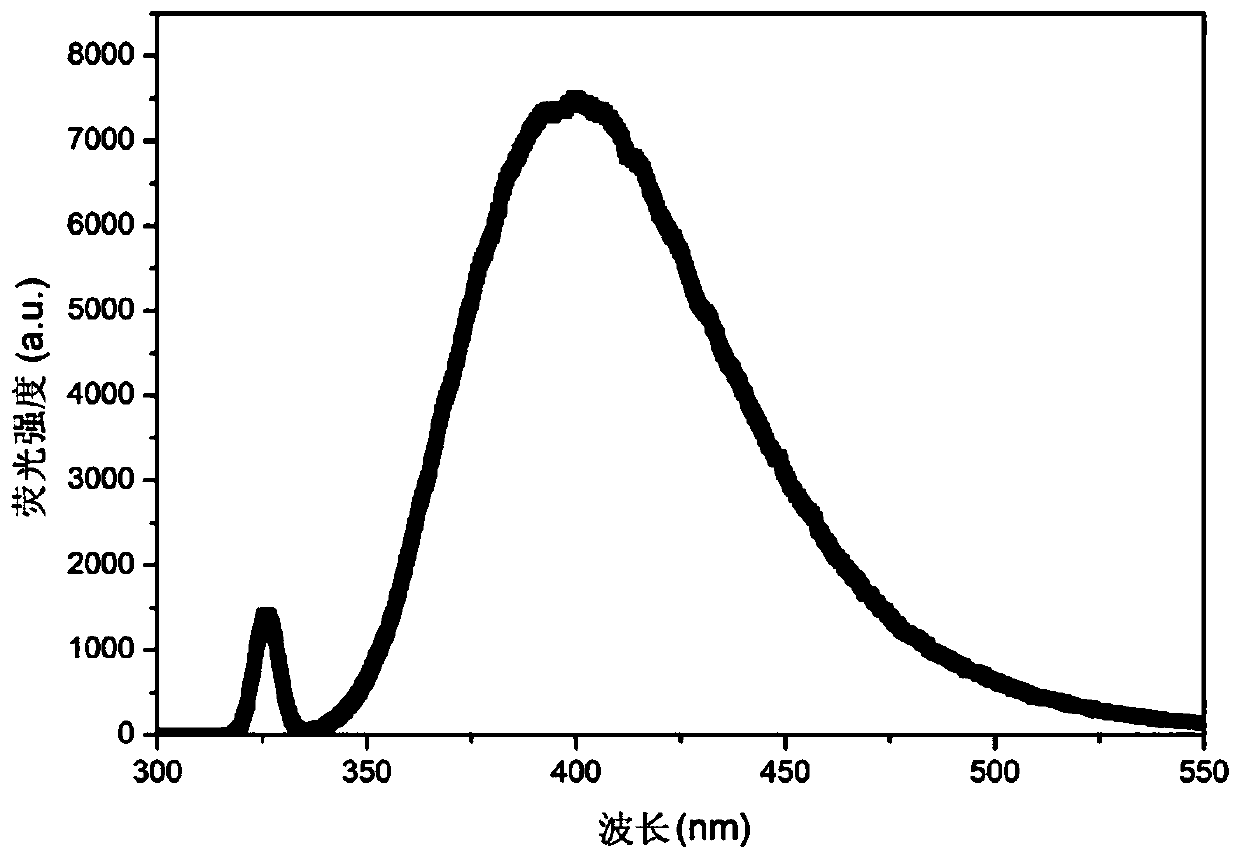

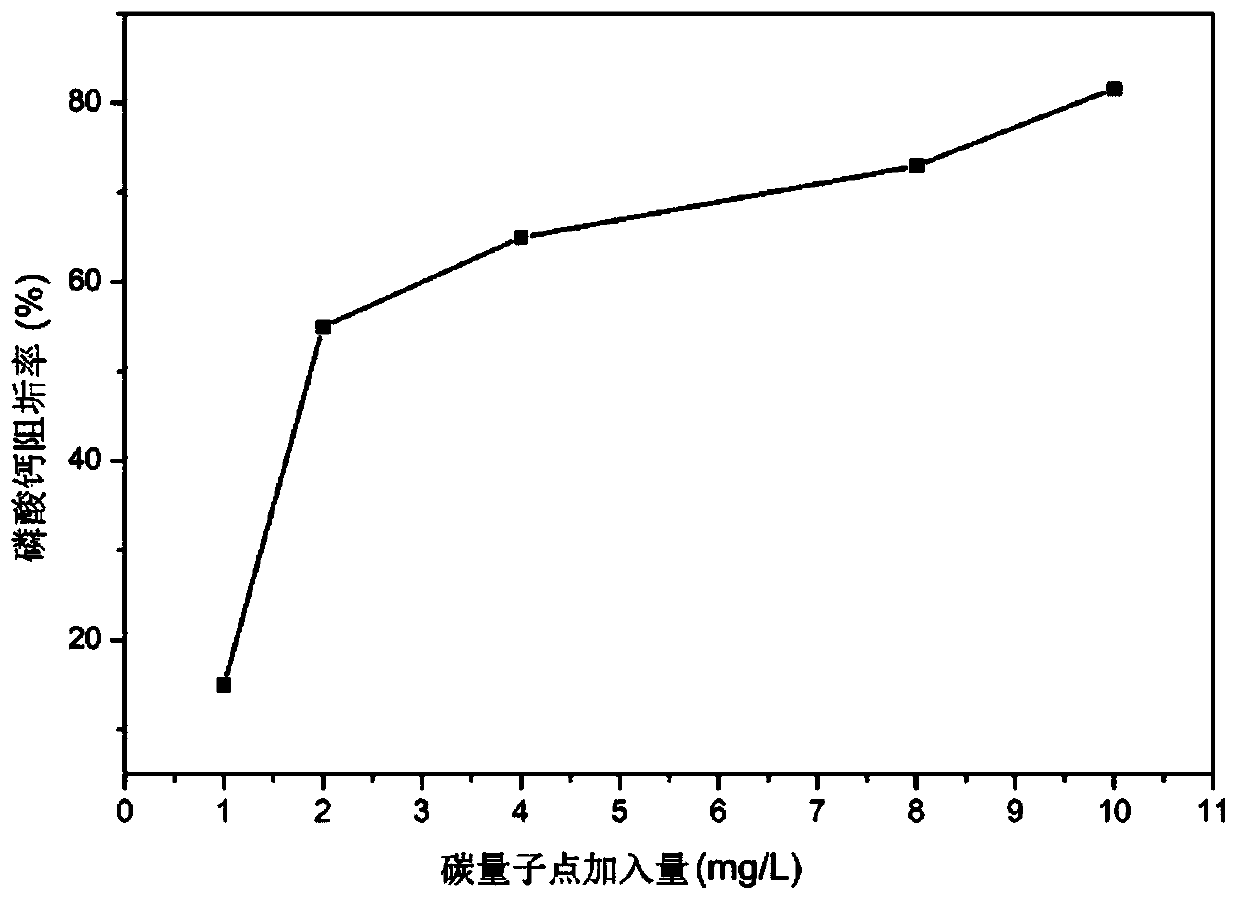

[0036] The carbon quantum dot solution prepared in this example was diluted to a carbon quantum dot concentration of 300 mg / L, and the diluted carbon quantum dot solution was detected by an ultraviolet-visible spectrophotometer. The result is as follows figure 1 Shown from figure 1 The maximum excitation wavelength is 325nm, the diluted ca...

Embodiment 2

[0038] A method for preparing fluorescent carbon quantum dots with scale inhibition performance includes the following steps:

[0039] Weigh 10.0 g polyacrylic acid (PAA) (50%, Tech), dissolve it in 35.0 g deionized water, add 2.5 g diethylene triamine and 2.5 g triethylene tetramine; mix the raw materials uniformly, and move to a closed polymerization Place the tetrafluoroethylene autoclave in an oven, set the temperature to 160℃, and react for 24 hours. After the reaction is completed, cool to room temperature naturally to obtain a brown reaction liquid; filter the reaction liquid to obtain a fluorescent carbon with scale inhibition performance Quantum dot solution.

Embodiment 3

[0041] A method for preparing fluorescent carbon quantum dots with scale inhibition performance includes the following steps:

[0042] Weigh 1.67g polyacrylic acid (PAA) (50%, Tech), dissolve it in 47.5g deionized water, add 1.67g diethylenetriamine; mix the raw materials uniformly, and move to a closed polytetrafluoroethylene high-pressure reactor , Placed in an oven, set the temperature to 200 DEG C, react for 9 hours, after the reaction is completed, naturally cool to room temperature to obtain a brown reaction liquid; filter the reaction liquid to obtain a fluorescent carbon quantum dot solution with scale inhibition performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com