Preparation method of modified polyaspartic acid copolymer

A polyaspartic acid and copolymer technology, applied in chemical instruments and methods, water/sludge/sewage treatment, descaling and water softening, etc. Simple and easy to operate, good anti-scaling performance, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

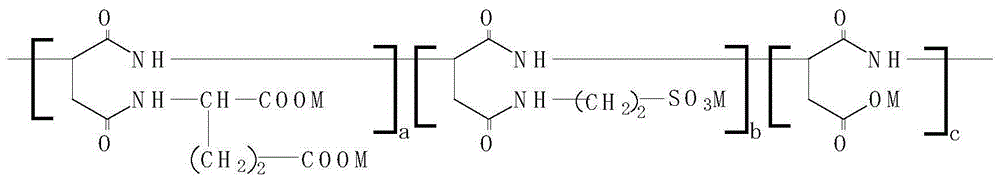

Image

Examples

Embodiment 1

[0030] Synthesis of polysuccinimide (PSI): in a four-necked flask equipped with a condenser tube, a thermometer, a constant pressure dropping funnel and an electric stirrer, put 9.8 g of maleic anhydride, a small amount of 5.7 g of urea in water, and stir to react After 1 hour, the maleic anhydride was completely dissolved, then 2.51 g of taurine was added, and stirred and reacted in a water bath at 85° C. for 2 hours. Add 40ml of sulfolane and 5.7g of phosphoric acid, raise the temperature to 180°C±5°C, and react for 2h in an environment of continuous nitrogen flow. Cool to room temperature after the reaction, add absolute ethanol for precipitation. Then perform suction filtration, wash with absolute ethanol and deionized water successively, and put the suction filtration into a constant temperature drying oven at 60° C. for drying. (The calculated intermediate yield was 96%). Synthesis of polyaspartic acid copolymer: react glutamic acid with sodium hydroxide solution to ge...

example 2

[0032] In the four-necked flask that condensing tube, thermometer, constant pressure dropping funnel and electric stirrer are housed, put into maleic anhydride 9.8g, 5.7g urea a small amount of water, stir reaction 1 hour, make maleic anhydride dissolve completely, then 10.01 g of taurine was put in, and stirred and reacted in a water bath at 85° C. for 2 hours. Add 40ml of sulfolane and 5.4g of phosphoric acid, raise the temperature to 180°C±5°C, and react for 2.5h in an environment of continuous nitrogen flow. Cool to room temperature after the reaction, add absolute ethanol for precipitation. Then perform suction filtration, wash with absolute ethanol and deionized water successively, and put the suction filtration into a constant temperature drying oven at 60° C. for drying. React glutamic acid with sodium hydroxide solution to generate the corresponding sodium salt solution for later use. Weigh a certain amount of product in a Erlenmeyer flask, add a small amount of wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com