Water-cooled bracing and dicing machine

A pelletizer, water-cooled technology, used in metal processing and other directions, can solve the problems of bumping knives, reduced service life of movable knives and fixed knives, and changes in gaps, and achieve the effects of improving service life, increasing production capacity, and novel structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

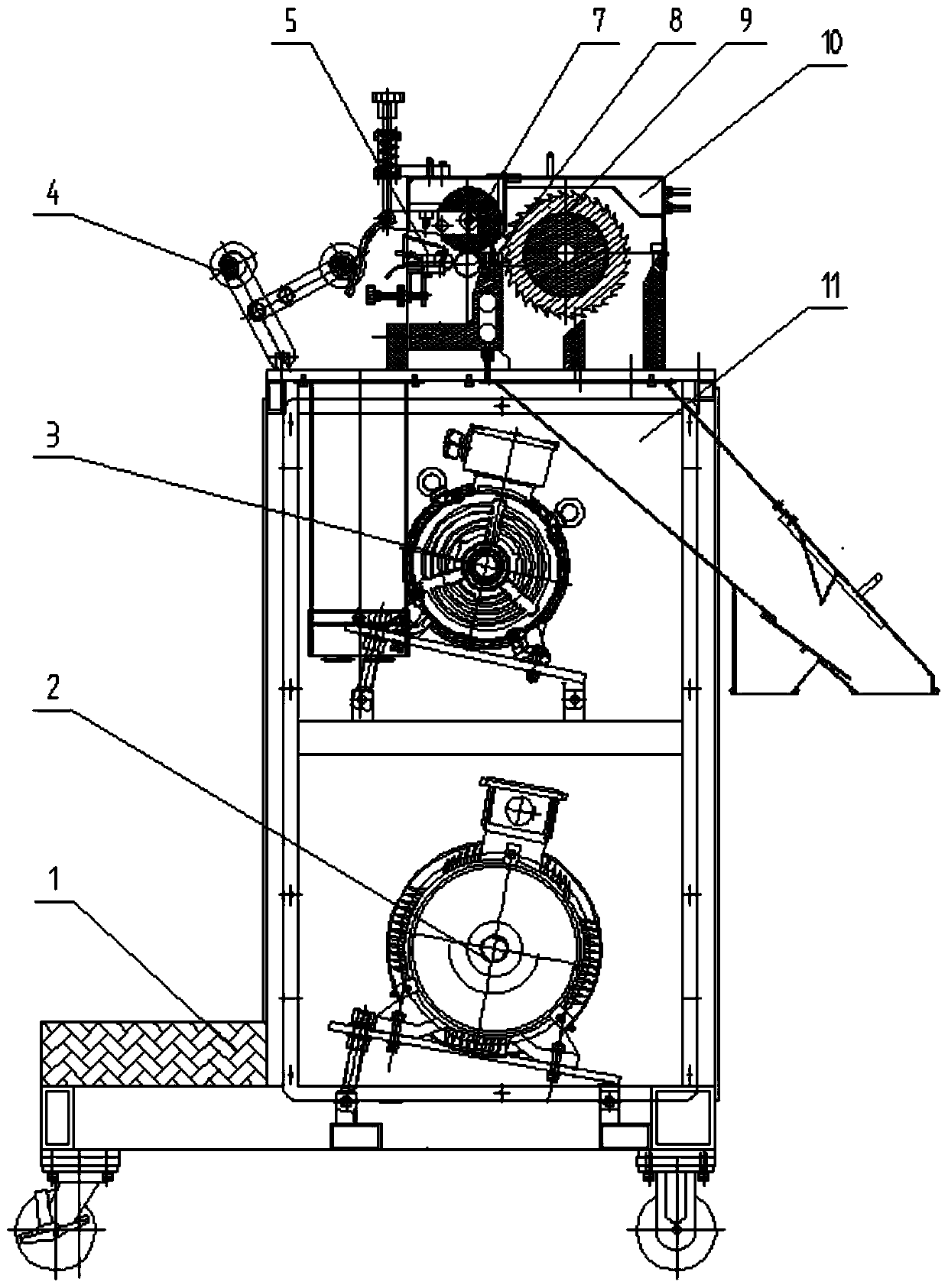

[0036] Such as figure 1 As shown, a water-cooled strand pelletizer includes: a strand pelletizer body for pelletizing strands 6; the strand pelletizer body includes a moving knife assembly 9; the moving knife The assembly 9 includes a moving knife shaft 16 and a moving knife 15 mounted on the moving knife shaft 16; a cooling water channel begins on the moving knife shaft 16.

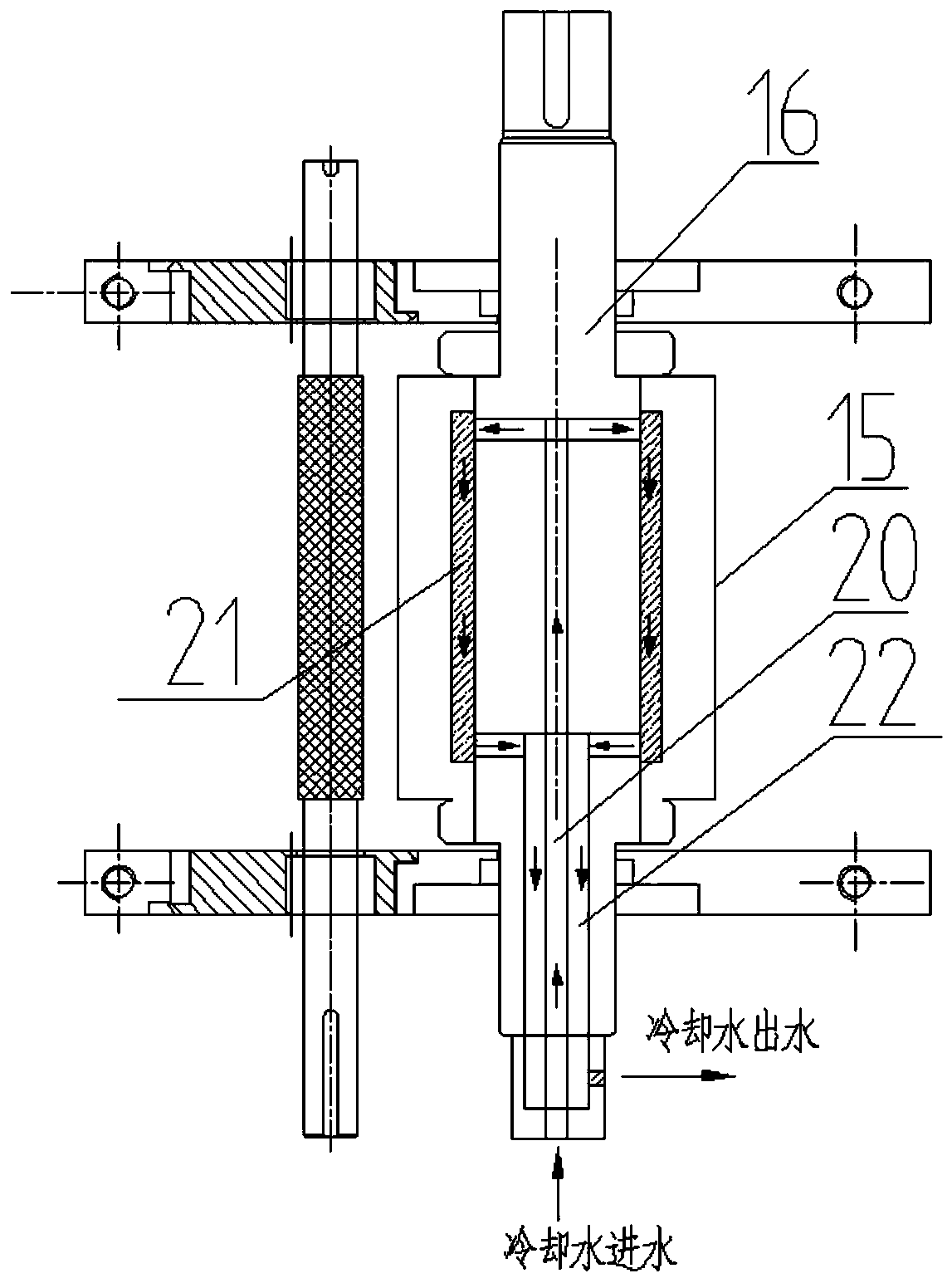

[0037] Such as image 3 As shown, this embodiment is mainly to improve and optimize the strand pelletizer body of the prior art, focusing on improving and optimizing the moving knife shaft 16 of the moving knife assembly 9, specifically: the cooling water The channels include a first channel 20, a second channel 21 and a third channel 22, the first channel 20 and the third channel 22 are all arranged in the moving knife shaft 16 and are independent of each other; the second channel 21 is opened on the moving knife Between the shaft 16 and the movable knife 15; one end of the first channel 20 is used to...

Embodiment 2

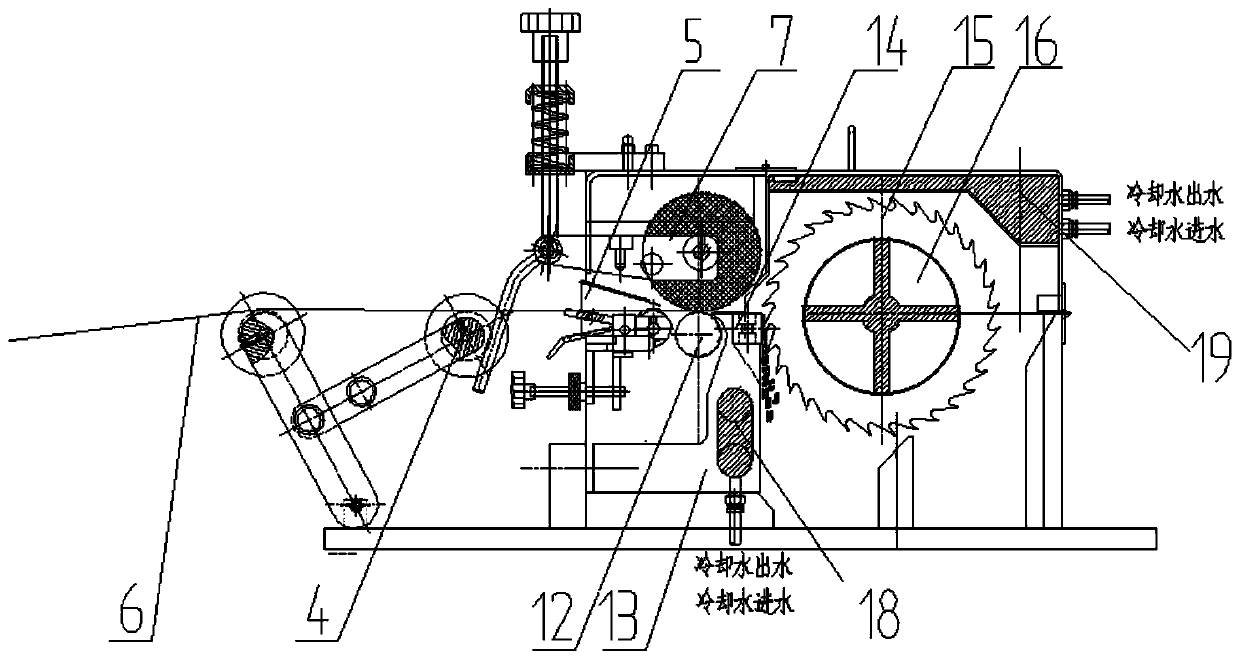

[0041] Such as figure 2 As shown, this implementation is further optimized on the basis of Embodiment 1. This embodiment focuses on the improvements compared with Embodiment 1, and the similarities will not be repeated. In this embodiment, the second channel 21 is a plurality of mutually independent water flow channels provided on the inner wall of the aperture of the movable knife shaft 16 or the movable knife 15 , and each water flow channel is communicated with the other end of the first channel 20 by a connecting channel. In this embodiment, the second channel 21 can be opened on the inner wall of the aperture of the movable knife 15 or on the movable knife shaft 16, as long as it is opened at the place where the movable knife shaft 16 and the inner wall of the aperture of the movable knife 15 are in contact. That's it.

[0042] Several mutually independent water flow channels are preferably arranged at equal intervals, so that the cooling water flows through evenly, so ...

Embodiment 3

[0044] Such as figure 2 As shown, this implementation is further optimized on the basis of Embodiment 2. This embodiment focuses on the improvements compared with Embodiment 2, and the similarities will not be repeated. In this embodiment, the second channel 21 is an annular water flow channel with a circular cross section opened on the inner wall of the aperture of the movable knife shaft 16 or the movable knife 15 , and the annular water flow channel communicates with the other end of the first channel 20 through one or more connecting channels.

[0045] The structure of the second passage 21 in this embodiment is a deformation of the second passage 21 in Embodiment 2. In this embodiment, the second passage 21 is an integral annular water flow passage, and the annular water flow passage or milling On the movable knife shaft 16, or milled on the inner wall of the aperture of the movable knife 15, the integral annular water flow channel has a better heat dissipation effect. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com