Composite nanofiltration membrane with heavy metal interception capability

A composite nanofiltration membrane and heavy metal technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of low mechanical strength, reduced membrane usability, weak binding force, etc., to avoid swelling separation, The effect of improving mechanical strength and increasing interlayer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of graphene oxide powder: adopt the Hummers method to prepare graphene oxide, specifically: add 50g sodium nitrate and 300g potassium permanganate to 100g flake graphite and stir evenly, then add 2000ml98% concentrated sulfuric acid to it under the condition of ice water bath After reacting for 2h, and then reacting at 30°C for 2h, add 4L of deionized water to the reaction system, keep it at 80°C for 30min, cool, then add 1L of 30% H 2 o 2 solution; centrifuged, and the product was acid-washed and dried to obtain graphene oxide powder for use;

[0037] Preparation of aminocucurbit[7]urea:

[0038] (1) Dissolve 1.4g cucurbituril[7] in 40ml of toluene solvent, add acid chloride solution, the molar ratio of CB[7] to acid chloride solution is 1:14, put the solution in an environment protected by inert gas, 60~ Heating to reflux at 80°C for 12-36 hours, distilling off the toluene to obtain imidazolium salt;

[0039] (2) Add 14ml of ammonia organic solution (7m...

Embodiment 2

[0053] Preparation of nanofibrous base film

[0054] Preparation of Basement Film 1

[0055] Take 5 g of the graphene oxide powder prepared in Example 1 and disperse it in 1 L of 30 g / L tyrosine hydrochloric acid solution (the concentration of the hydrochloric acid solution is 1 mol / L), and ultrasonicate at 60° C. for 10 h; to obtain a graphene dispersion, add 50g carboxymethyl hydroxypropyl guar gum and 100g polyacrylamide; fully stir to obtain the spinning solution; inject the spinning solution into the syringe pump of the spinning device, and obtain the nanofiber membrane through electrospinning, and the nanofiber membrane is obtained from Take it off the metal substrate, soak it in boric acid and glutaraldehyde mixed solution, take it out to obtain the base film 1, and set it aside; wherein, the electrospinning voltage is 14kV, the needle diameter of the syringe pump is 1mm; the flow rate of the syringe pump is 0.1mL / h , the spinning distance is 16cm, the spinning tempera...

Embodiment 3

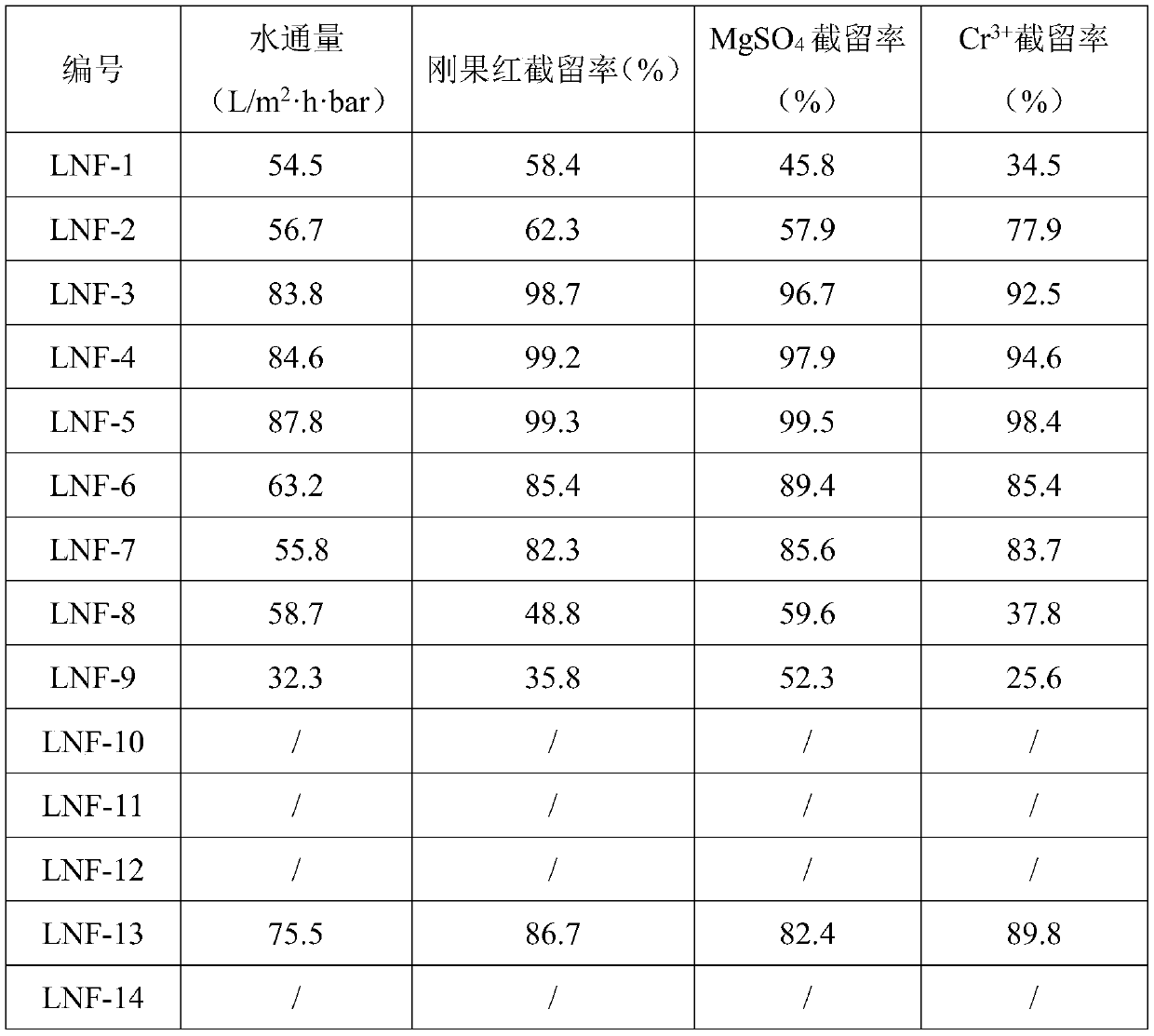

[0070] Preparation of Composite Nanofiltration Membrane with Heavy Metal Retention Capability

[0071] (1) Preparation of aminocucurbituril intercalated graphene oxide dispersion (same as Example 1)

[0072] (2) preparation of base film (same as embodiment 2)

[0073] (3) Deposit the aminocucurbituril intercalated graphene dispersion 1-9 obtained in the embodiment onto the base film in step (2) by vacuum filtration to obtain a composite nanofiltration membrane with heavy metal interception capacity, which is sequentially denoted as LNF- 1. LNF-2, LNF-3, LNF-4, LNF-5, LNF-6, LNF-7, LNF-8, LNF-9;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Needle diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com