Composite type energy absorbing device with thin-wall metal tube filled based on cut honeycomb structure

A honeycomb structure and energy-absorbing device technology, applied in the direction of shock absorbers, springs, springs/shock absorbers, etc., can solve the problems of high blade material and processing technology requirements, difficult energy absorption control, and single energy absorption method. Achieve low blade material and shape requirements, facilitate the evaluation of energy absorption effect, and achieve good energy absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

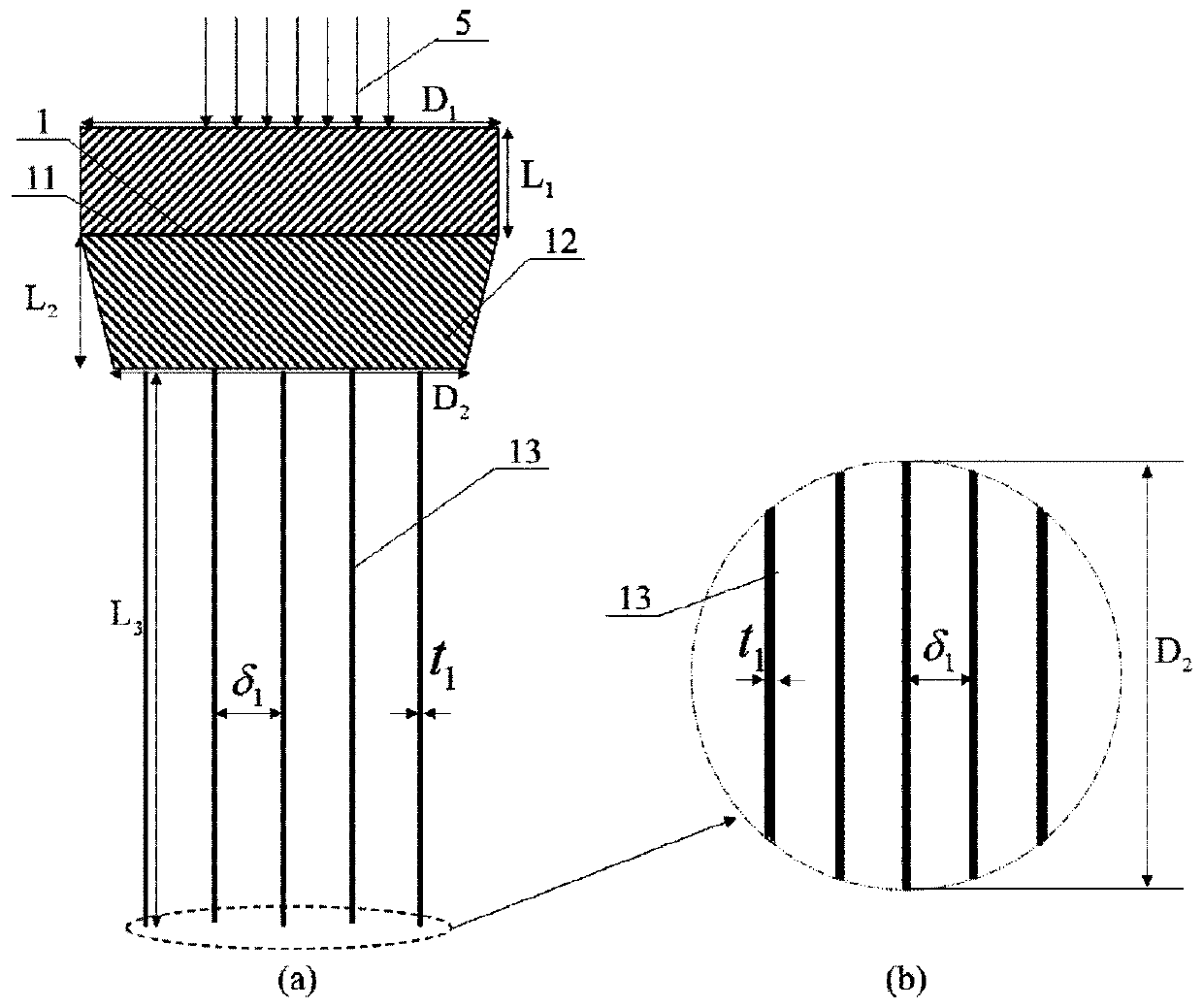

[0029] In order to more clearly illustrate the technical solutions in the embodiments of the present invention, the following will introduce the drawings that need to be used in the embodiments or the description of the prior art. Obviously, the drawings in the following description are only part of the implementation of the present invention example, not all examples. Based on the embodiments of the present invention, those skilled in the art can also obtain other drawings based on these drawings without any creative effort.

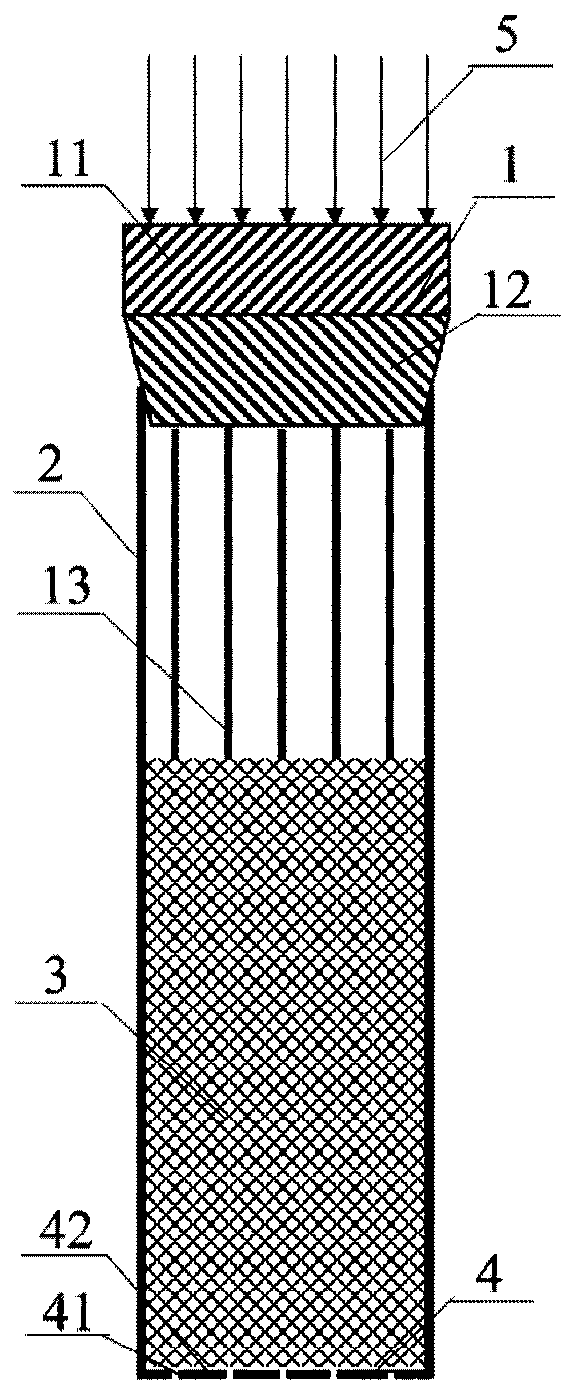

[0030] figure 1 It is a partial sectional view of the overall structure of the present invention. Such as figure 1 As shown, the compound energy-absorbing device of the present invention based on the cut honeycomb structure filled with thin-walled metal pipes consists of a wedge-shaped expansion block 1, a thin-walled metal pipe 2, a honeycomb structure 3, and a gas leakage protection chassis 4.

[0031] figure 2 for figure 1 Middle AA' sectional ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com