Integral steel platform jacking oil cylinder oil circuit controlling system

A jacking cylinder and control system technology, applied in fluid pressure actuation system components, fluid pressure actuation devices, servo motor components, etc., can solve problems such as damaged components, hidden safety hazards of the overall steel platform system, and ensure safe operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

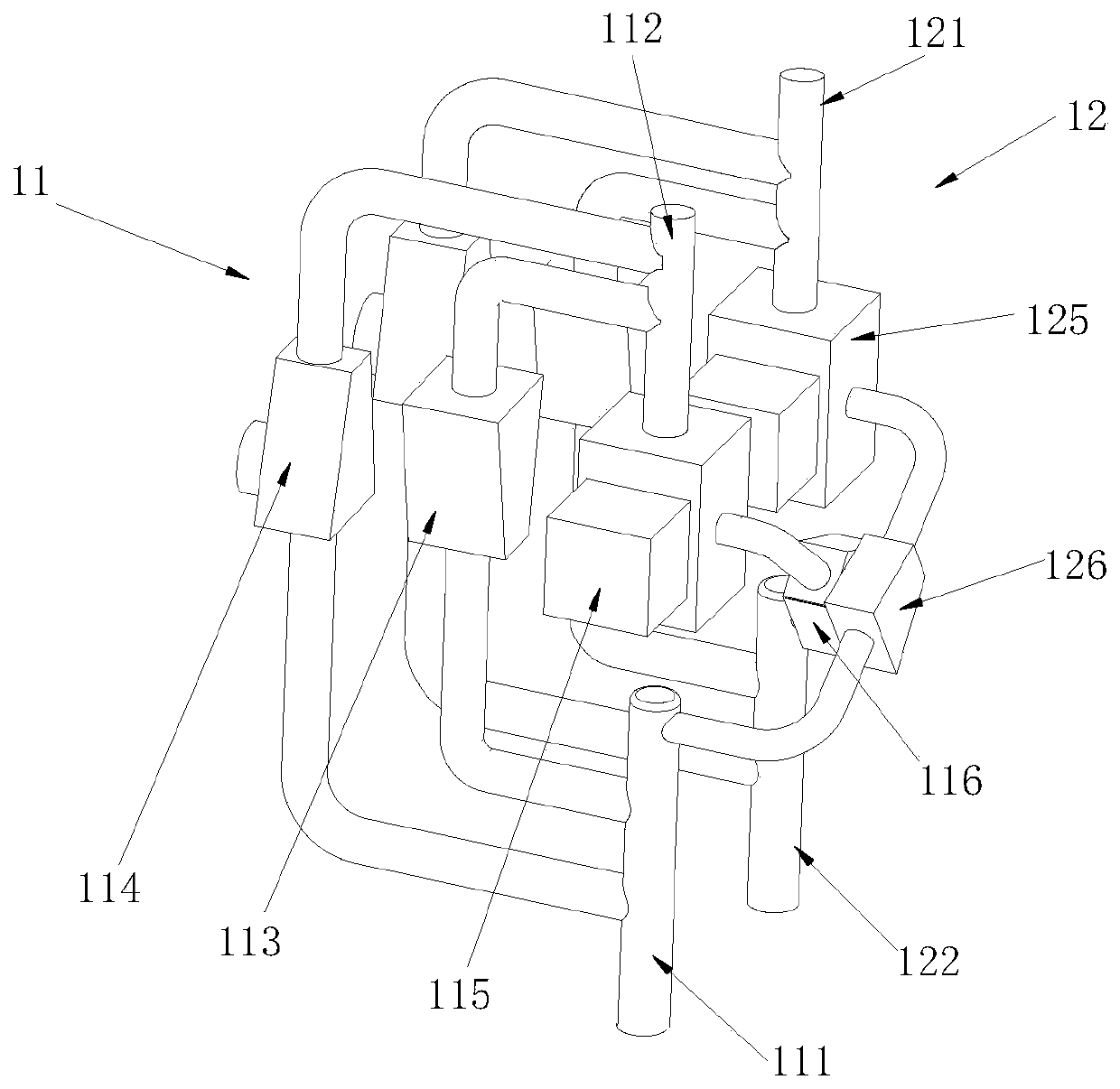

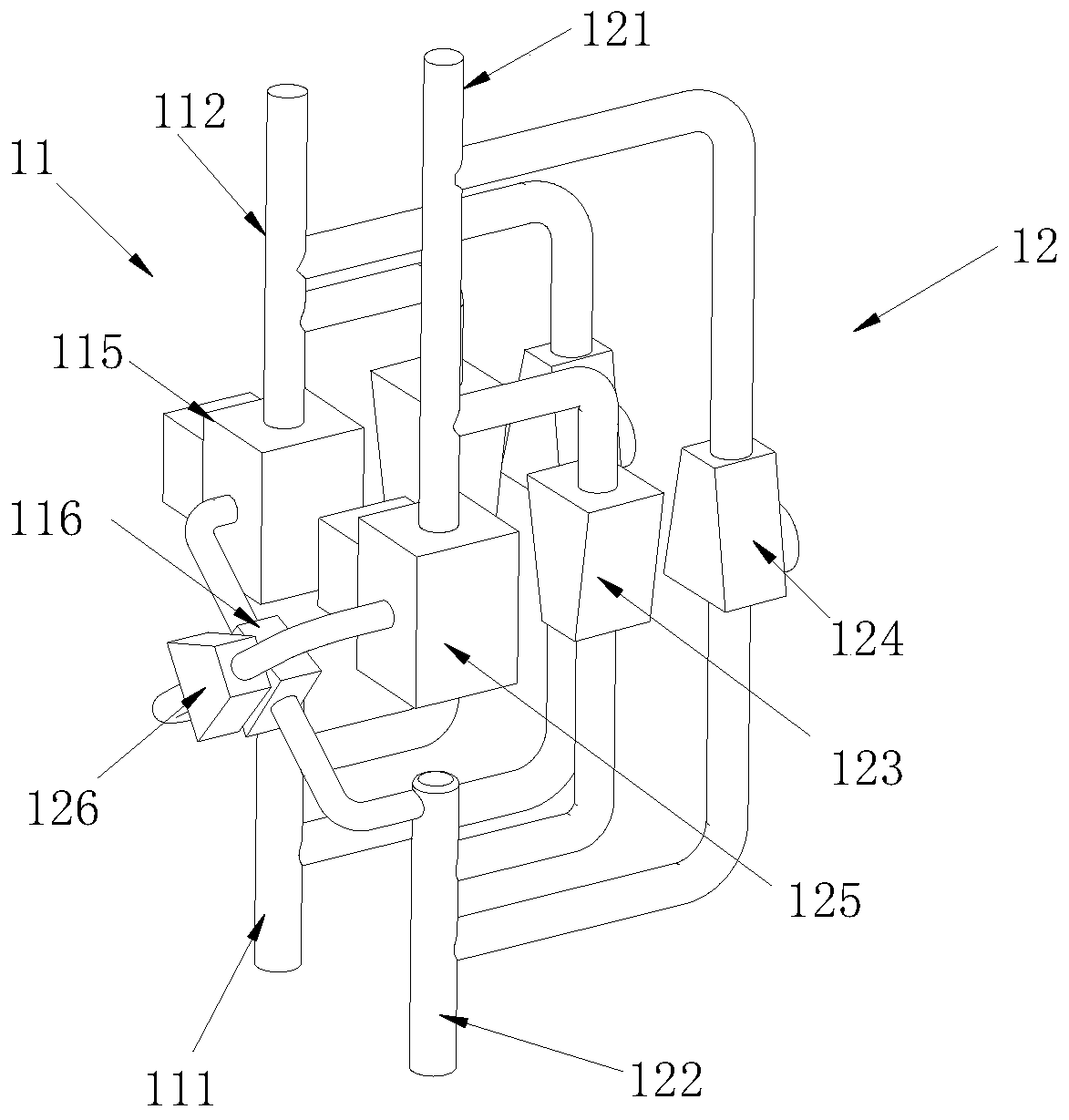

[0037] combine figure 1 and figure 2 As shown, this embodiment discloses a hydraulic cylinder oil circuit locking valve group 10 , and the locking valve group 10 includes a first unit module 11 and a second unit module 12 . Unit module 11 includes oil pipe 1 111, oil pipe 2 112, hydraulic control check valve 1 113, electromagnetic check valve 1 114, overflow valve 1 115, unloading check valve 1 116; unit module 2 12 includes oil pipe 3 121 , oil pipe four 122, hydraulic control check valve two 123, electromagnetic check valve two 124, overflow valve two 125, unloading check valve two 126; said oil pipe one 111, oil pipe two 112, oil pipe three 121, oil pipe four One end of 122 is provided with a plurality of oil ports, and the other end is an external oil port.

[0038] The oil inlet of the hydraulically controlled one-way valve 113, the oil outlet of the electromagnetic one-way valve 114, and the oil outlet of the unloading one-way valve 126 are respectively communicated w...

Embodiment 2

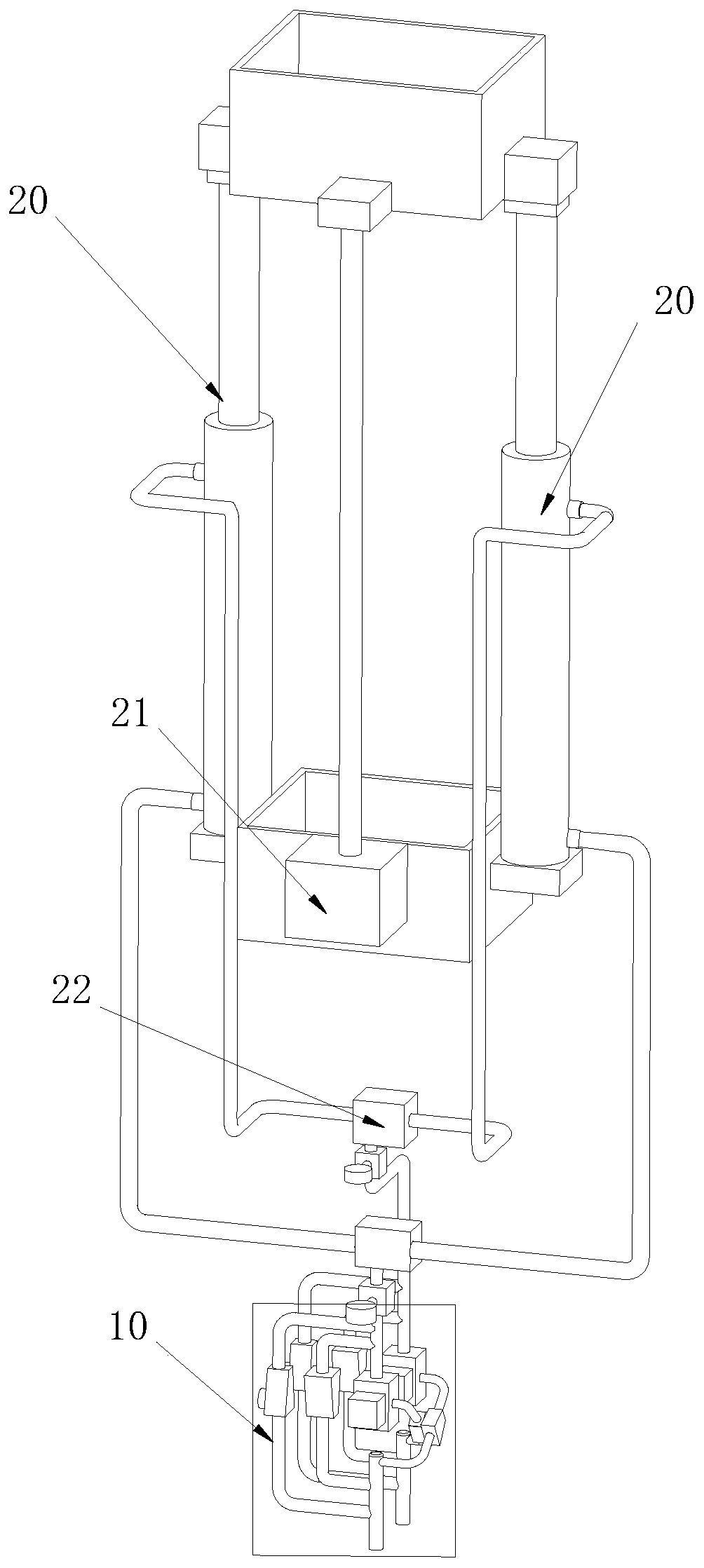

[0045] image 3 A connection relationship diagram between the hydraulic cylinder oil circuit locking valve group 10 and the jacking cylinder 20 is disclosed. Such as image 3 As shown, one locking valve group 10 controls two jacking cylinders 20 at the same time, of course, it can also control more or one, and the principle is the same. The jacking cylinder 20 includes two chambers. According to the position of the plunger rod of the jacking cylinder, the two chambers are respectively called the rodless chamber and the rod chamber. Both the rodless chamber and the rod chamber are provided with oil ports.

[0046] combine Figure 1 to Figure 3 As shown, the external oil port of the oil pipe 2 112 is connected with the oil port of the rodless chamber of the jacking cylinder 20 , and the external oil port of the oil pipe 3 121 is connected with the oil port of the rod chamber of the jacking cylinder 20 . In this case, the working mode one of the above-mentioned locking valve g...

Embodiment 3

[0050] Figure 4 A connection relation diagram between the locking valve group 10 and the three-position four-way proportional reversing valve 7 is disclosed. The external oil port of the first oil pipe 111 and the external oil port of the oil pipe four 122 are respectively connected with the three-position four-way proportional reversing valve 7, and the three-position four-way proportional reversing valve 7 is used to realize that the jacking cylinder 20 is extending the cylinder, When shrinking the cylinder in different working conditions, the hydraulic oil flow direction in the jacking cylinder 20 is changed.

[0051] The three-position four-way proportional reversing valve 7 includes an oil inlet P, an oil port A, an oil port B, and an oil return port T, wherein the oil port A and the oil port B are respectively connected to the external oil ports of oil pipe one 111 and oil pipe four 122 connected. The three-position four-way proportional reversing valve 7 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com