Reactor single-layer safety shell and construction method thereof

A containment and reactor technology, which is applied in the fields of reactors, nuclear engineering, industrial buildings, etc., can solve problems such as the overhaul and replacement of large equipment, high internal environment requirements, and more time for equipment to arrive at the scene, so as to reduce the dead weight of the structure and improve the aircraft. Impact performance and the effect of improving structural mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

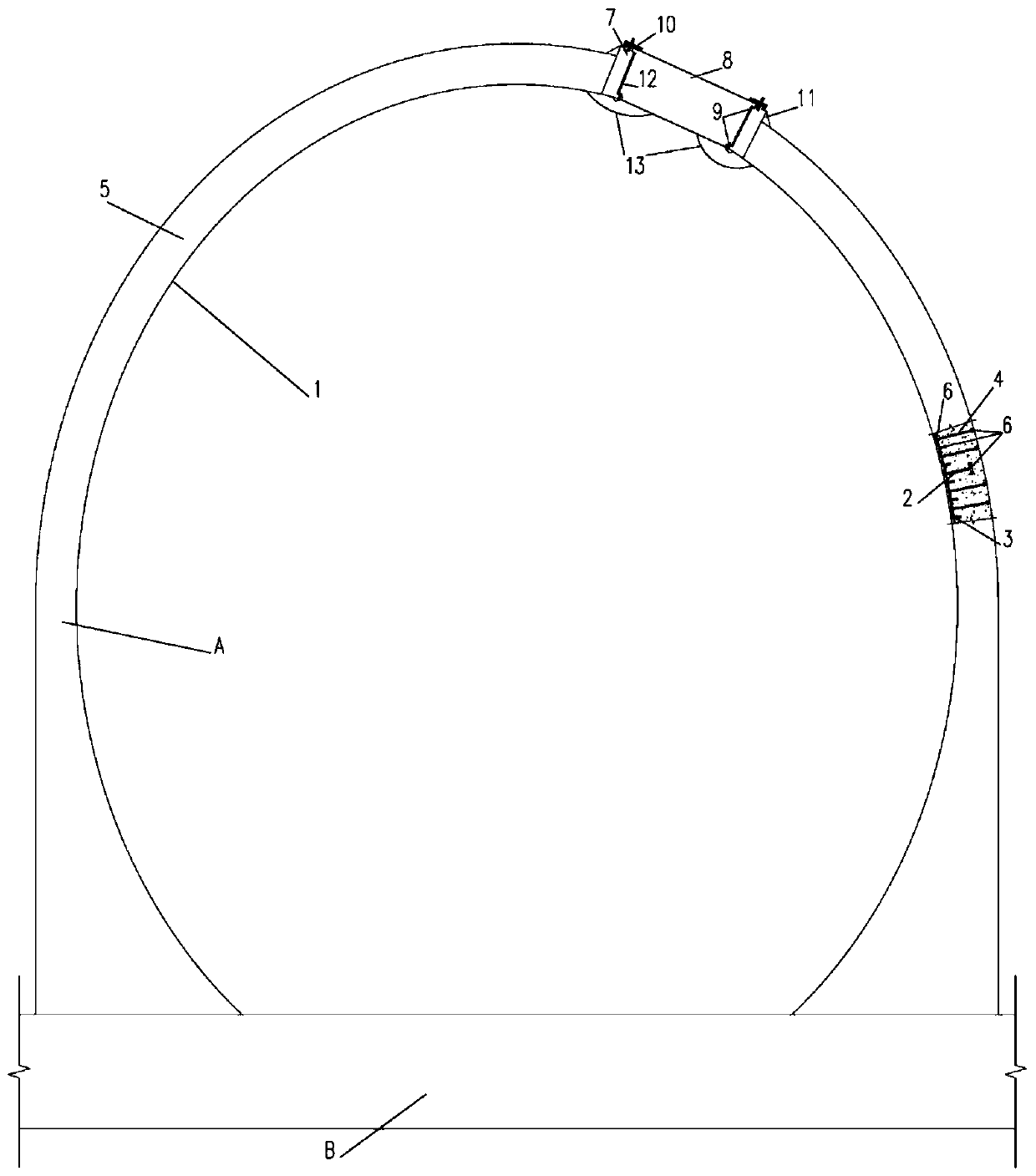

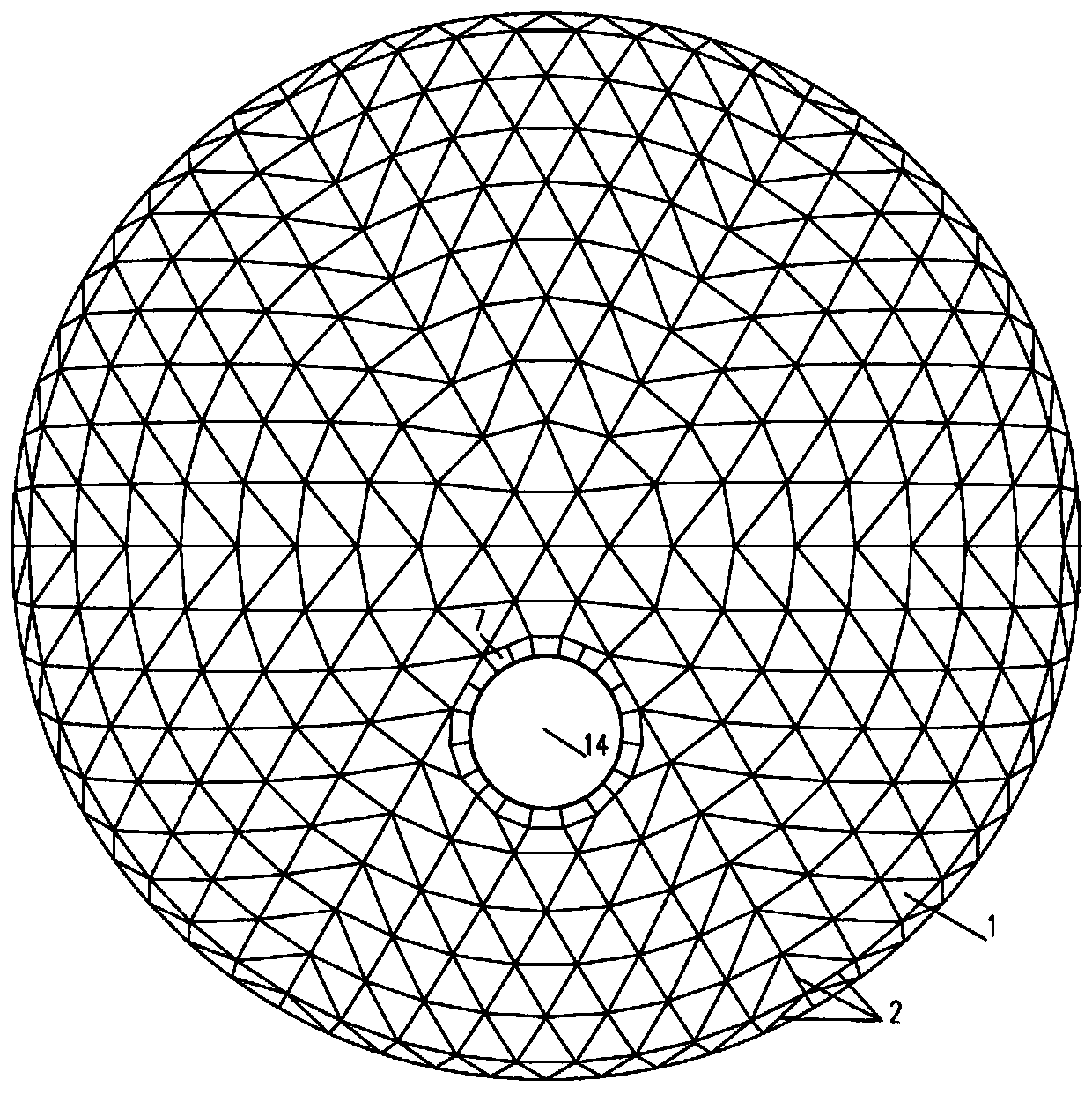

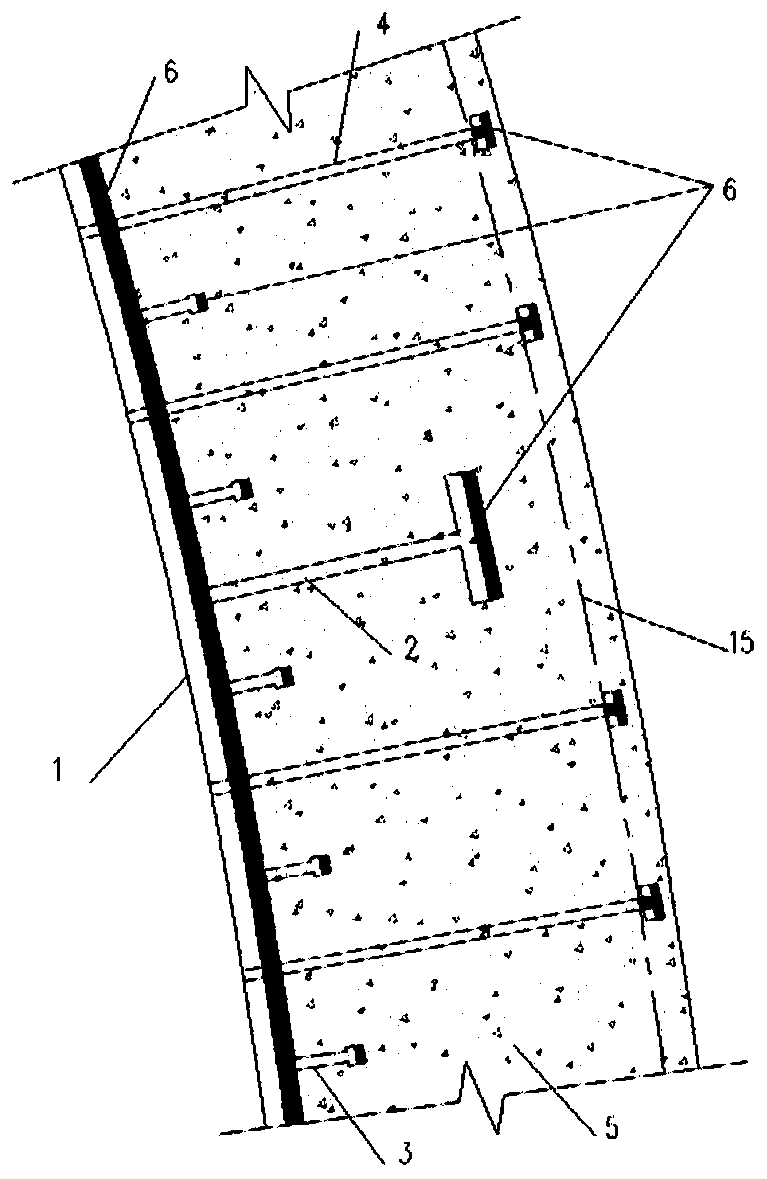

[0029] The reactor single-layer containment vessel proposed by the present invention has a structure such as figure 1 and figure 2 As shown in , the single-layer containment vessel of the reactor is composed of the lower shell part and the upper dome part, and the shell and the dome are made of steel plate 1 and concrete structure of shear-one-way non-pull-resistant member; the steel plate 1 is set in the safe On the inner side of the shell, the shear-unidirectional non-pullout members are evenly distributed on the steel plate, and the shear-unidirectional non-pullout members are composed of stiffeners 2, pegs 3 and belt straights arranged in an oblique or orthogonal grid. The smooth shear reinforcement 4 of the threaded anchor plate is composed of the stiffener 2, the stud 3 and the smooth shear reinforcement 4 of the anchor plate with straight threads respectively welded and fixed to the steel plate 1, and the upper end of the smooth shear reinforcement 4 passes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com