Method for co-producing sulfuric acid by synergistically reducing gypsum with gaseous sulfur and high-sulfur bauxite to produce sulphoaluminate cement

A technology for producing high-sulfur bauxite and sulfoaluminate, applied in cement production, chemical instruments and methods, sulfur compounds, etc., can solve the problems of not meeting concentration requirements, high operating costs, high investment and energy consumption, and achieve The effect of reducing consumption, reducing production costs and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] F. Preparation of cement

[0089] Sulphoaluminate cement products with different performance requirements are obtained by adding gypsum and composite materials to the cement clinker from the cooler in step E, and then undergoing subsequent grinding processing.

Embodiment 1

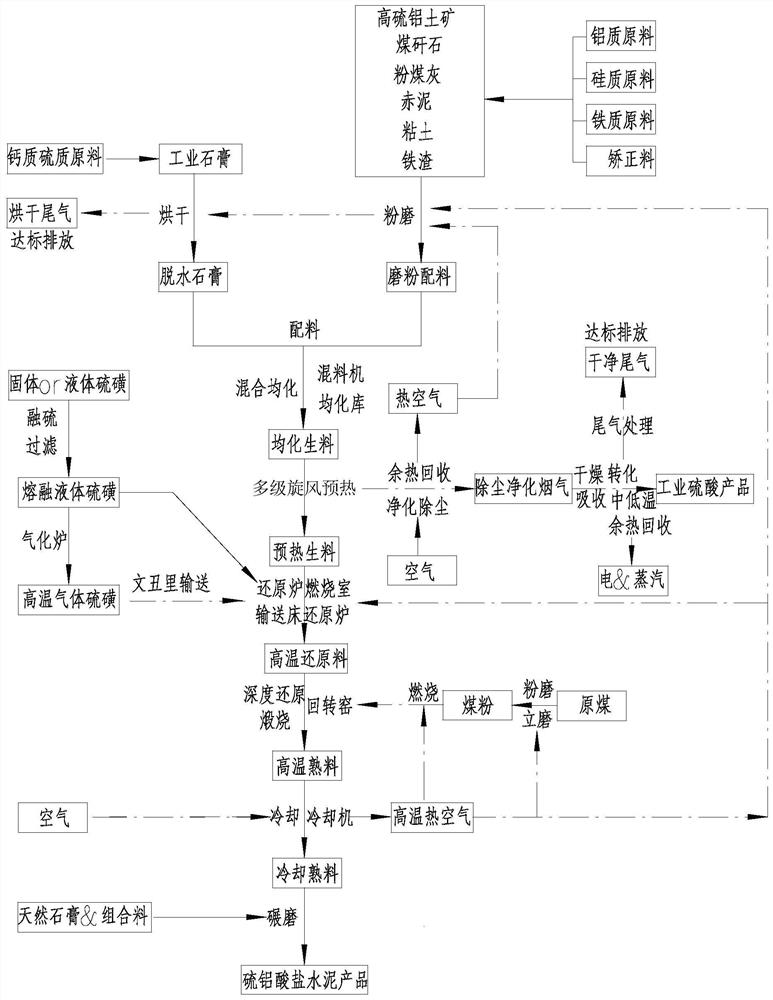

[0092] process such as figure 2 As shown, phosphogypsum and high-sulfur bauxite are used as raw materials. The raw materials are dried and ground to >95%-80μm, and most of the fly ash produced by the combustion of fuel coal in the rotary kiln enters the clinker. The chemical composition is shown in Table 1.

[0093] Table 1 Chemical composition of raw materials and raw meal

[0094] project CaO SiO 2

Al 2 o 3

Fe 2 o 3

MgO P 2 o 5

Na 2 o

SO 3

LOSS total Phosphogypsum 32.56 4.76 0.97 0.39 0.31 1.05 0.30 43.63 15.98 99.95 High sulfur bauxite 3.70 2.26 54.14 17.23 0.07 0.00 0.13 16.37 5.25 99.16 Raw material 25.14 4.12 14.81 4.77 0.25 0.78 0.26 36.65 13.23 100.00

[0095] The above-mentioned phosphogypsum dihydrate and high-sulfur bauxite raw materials are composed by weight: 74 parts of phosphogypsum dihydrate and 26 parts of high-sulfur medium-grade bauxite are mixed ev...

Embodiment 2

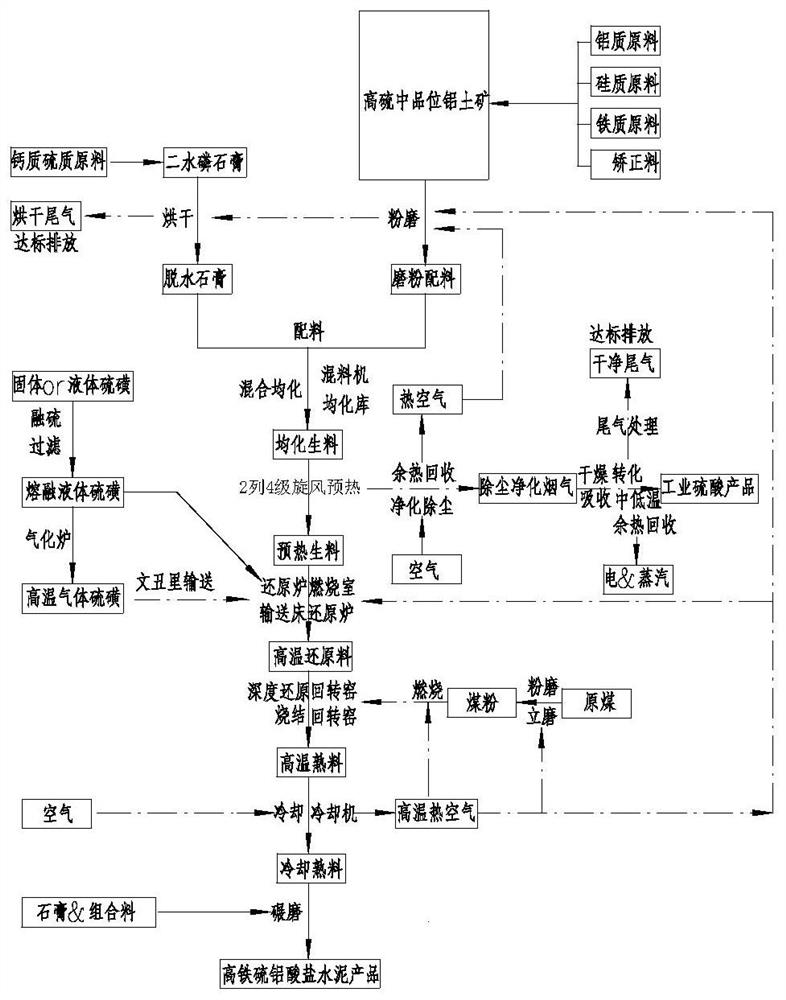

[0104] process such as image 3 As shown, desulfurized gypsum and high-sulfur bauxite are used as raw materials. The raw materials are dried and ground to >95%-80μm, and most of the fly ash produced by the combustion of fuel coal in the rotary kiln enters the clinker. The chemical composition is shown in Table 4.

[0105] Table 4 Chemical Composition of Raw Materials and Raw Meals

[0106] project CaO SiO 2

Al 2 o 3

Fe 2 o 3

MgO TiO 2

Na 2 o

SO 3

LOSS total Desulfurization gypsum 34.35 1.56 1.78 1.15 2.24 0.12 0.15 41.56 17.06 99.97 High sulfur bauxite 3.71 4.36 61.32 11.18 0.07 0.58 0.13 11.37 7.25 99.97 Raw material 25.21 2.40 19.57 4.15 1.59 0.26 0.14 32.55 14.13 100.00

[0107] The above-mentioned desulfurization gypsum and high-sulfur bauxite raw materials are composed by weight: 70.1 parts of desulfurization gypsum and 29.9 parts of high-sulfur bauxite are mixed ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com