A self-pressurization system for nitrous oxide decomposition

A nitrous oxide, self-pressurization technology, applied in the direction of machine/engine, rocket engine device, jet propulsion device, etc., to achieve the effect of reducing volume and weight, low price, and ensuring the ability to stabilize voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the present invention will be further described in conjunction with the drawings and embodiments.

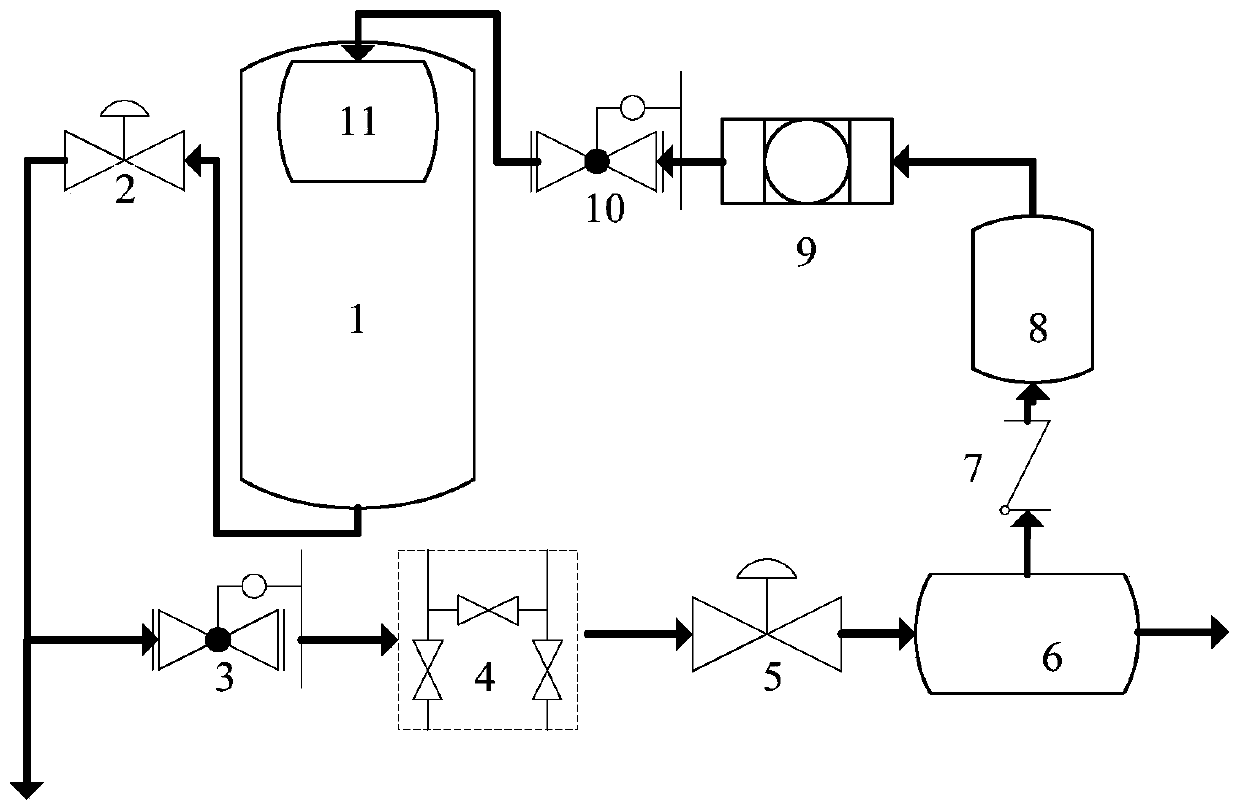

[0021] Please refer to figure 1 , a nitrous oxide self-increasing system provided by the present invention includes: a nitrous oxide storage tank 1 with a pressurized air bag 11 inside, a diaphragm valve 2, a small supercharger 3, a flow regulator 4, and a controller 5. Decomposer 6, one-way valve 7, cooler 8, filter 9, voltage regulator 10, control subsystem (not marked in the figure) and various connecting pipelines.

[0022] The pressurized air bag 11 is pre-filled with an appropriate amount of pressurized gas (helium, nitrogen, etc.), and when the standby command of the power unit is issued, the diaphragm valve 2 is opened, and the liquid nitrous oxide in the nitrous oxide storage tank 1 is pressurized. Under the action of the airbag 11, it is delivered to each subsystem and before the decomposer, and enters the system standby state. After the official ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com