A plate rolling device and method based on magnetic pulse impact modification

A technology of impact modification and impact device, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of easy cracking, uneven work hardening, coarse grains, etc. The effect of low cost and fine grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

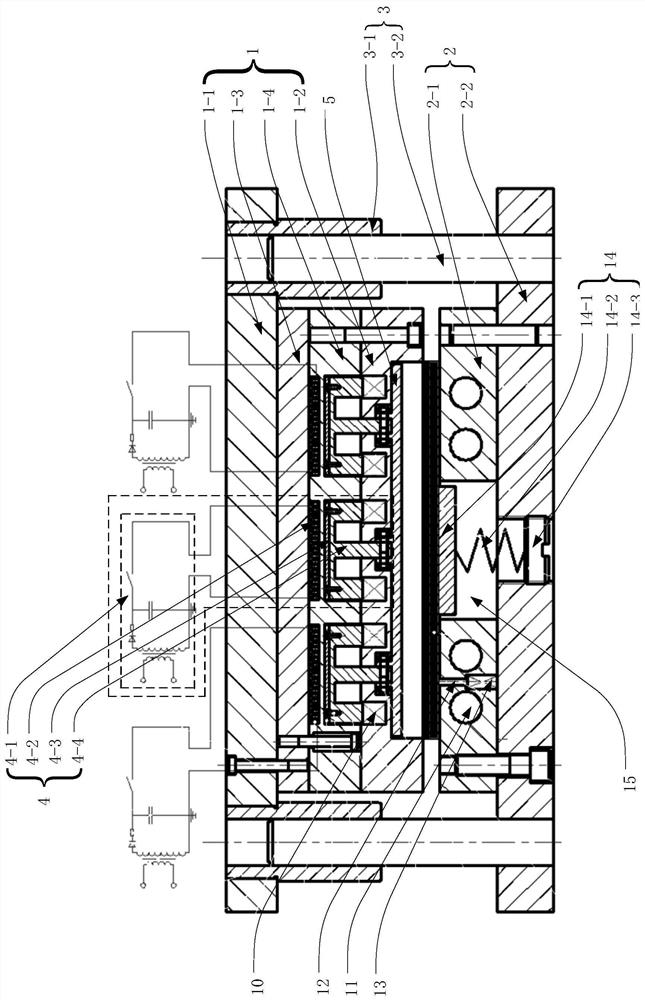

[0037] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS First, a sheet rolling device based on magnetic pulse impact modification in this embodiment includes an impact die, a magnetic pulse impact unit and a heating device 11;

[0038] The impact die includes an upper die 1, a lower die 2 and a guide device 3;

[0039] The upper mold 1 and the lower mold 2 are arranged correspondingly up and down, and a guide device 3 is connected between the upper mold 1 and the lower mold 2, and the upper mold 1 can move relative to the lower mold 2 through the guide device 3;

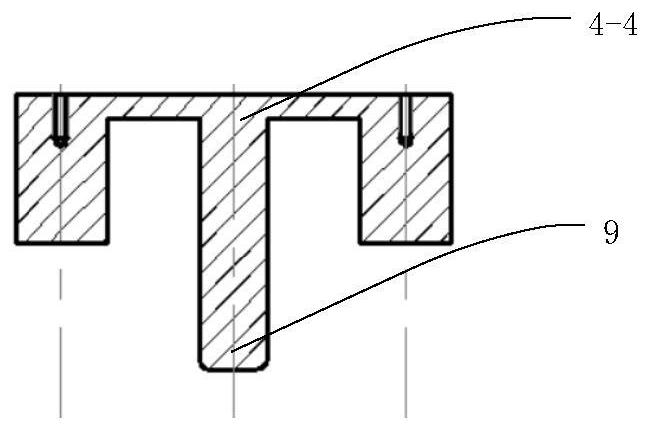

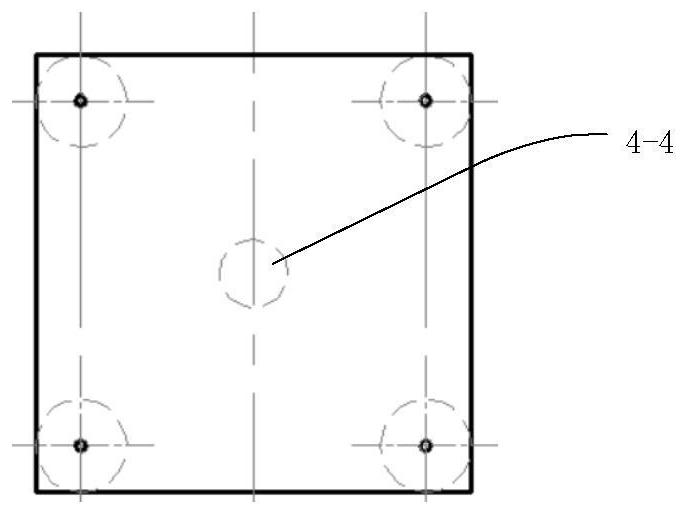

[0040] The magnetic pulse impact unit includes at least one impact drive device 4 and one impact plate 5;

[0041] At least one impact driving device 4 is arranged in the upper mold 1, and the impact driving device 4 can impact or reset in the direction of the lower mold 2 relative to the upper mold 1;

[0042] The bottoms of all impact driving devices 4 are fixed with the top surface of the impact plate 5, so that...

specific Embodiment approach 2

[0096] Specific embodiment 2, the rolling method of the plate rolling device based on the magnetic pulse impact modification of the present embodiment, the method is as follows:

[0097] Step 1. Move the upper mold upward, and place the plate to be impacted on the lower mold;

[0098] Step 2: Turn on the magnetic pulse power supply to energize the flat coil, and the flat coil generates an electromagnetic force that acts on the metal drive plate, so that the metal drive plate drives the impact device connector to move downward, thereby causing the impact plate to impact the plate to be impacted;

[0099] Step 3: Heat treatment of the impacted plate by means of a heating device. After the heat treatment is completed, the rolling is completed.

[0100] The best embodiment, this embodiment is a further description of the second embodiment. In this embodiment, step 1 further includes heating the plate to be impacted by a heating device, and detecting the temperature of the plate to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com