Method for determining helium concentration depth distribution in metal material by using radio frequency glow discharge spectrometer

A radio frequency glow discharge, metal material technology, applied in material excitation analysis, electrical excitation analysis and other directions, to achieve the effect of simple operation, accurate draft, and large detection depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

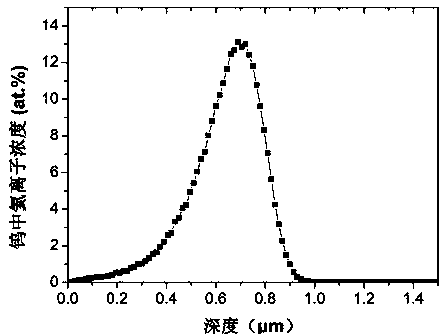

[0020] (1) Standard sample: high-energy helium ions are implanted into tungsten (purity 99.99%) metal through an ion implanter (NEC 400kV) to obtain a standard sample. The energy of implanting helium ions was 400 keV, and the ion beam density was 1.5×10 13 cm -2 the s -1 , with an injection dose of 2.6×10 17 He / cm 2 ;

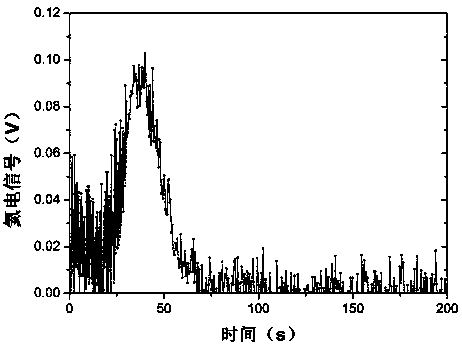

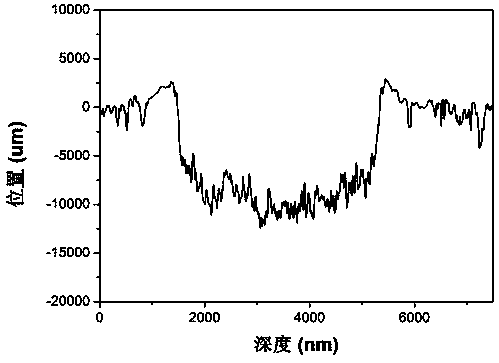

[0021] (2) Radio frequency glow discharge spectroscopy detection: use a radio frequency glow discharge spectrometer (the model GD PROFILER 2 produced by Horiba Jobin Yvon, France) to test the concentration distribution of helium in the depth direction on the standard sample after helium injection, and get Electrical signal-time curve of helium element. The specific working conditions are: the excitation method is RF, the anode size is 4mm, the vacuum chamber pressure is 500Pa, the frequency is 3000Hz, the power is 15W, the module value is 6.8V, and the phase value is 6.0V. figure 1 Obtain the electrical signal-time curve of helium in the depth direction ...

Embodiment 2

[0026] (1) Standard sample: high-energy helium ions are implanted into copper (purity 99.99%) metal material through an ion implanter (NEC 400kV) to obtain a helium-copper sample. The energy of implanting helium ions was 400 keV, and the ion beam density was 1.5×10 13 cm -2 the s -1 , with an injection dose of 2.6×10 17 He / cm 2 ;

[0027] (2) Radio frequency glow discharge spectrum detection: the specific working conditions are the same as in Example 1;

[0028] (3) Obtain the sputtering rate of the standard sample by non-contact optical profilometry: the specific calibration process is the same as that in Example 1;

[0029] (4) Electrical signal-time curve is converted into electrical signal-depth curve: the specific calculation process is the same as that in Example 1;

[0030] (5) The distribution curve of the helium element concentration in the copper sample in the depth direction: the distribution curve of the helium element concentration in the copper sample in t...

Embodiment 3

[0032] (1) Standard sample: implant high-energy helium ions into EUROFER steel material through an ion implanter (NEC 400kV) to obtain a helium-containing EUROFER steel sample. The energy of implanting helium ions was 400 keV, and the ion beam density was 1.5×10 13 cm -2 the s -1 , with an injection dose of 2.6×10 17 He / cm 2 ;

[0033] (2) Radio frequency glow discharge spectrum detection: the specific working conditions are the same as in Example 1;

[0034] (3) Obtain the sputtering rate of the standard sample by non-contact optical profilometry: the specific calibration process is the same as that in Example 1;

[0035] (4) Electrical signal-time curve is converted into electrical signal-depth curve: the specific calculation process is the same as that in Example 1;

[0036] (5) The distribution curve of the helium element concentration in the copper in the depth direction: use the sputtering rate obtained above and the determined helium element electrical signal-con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com