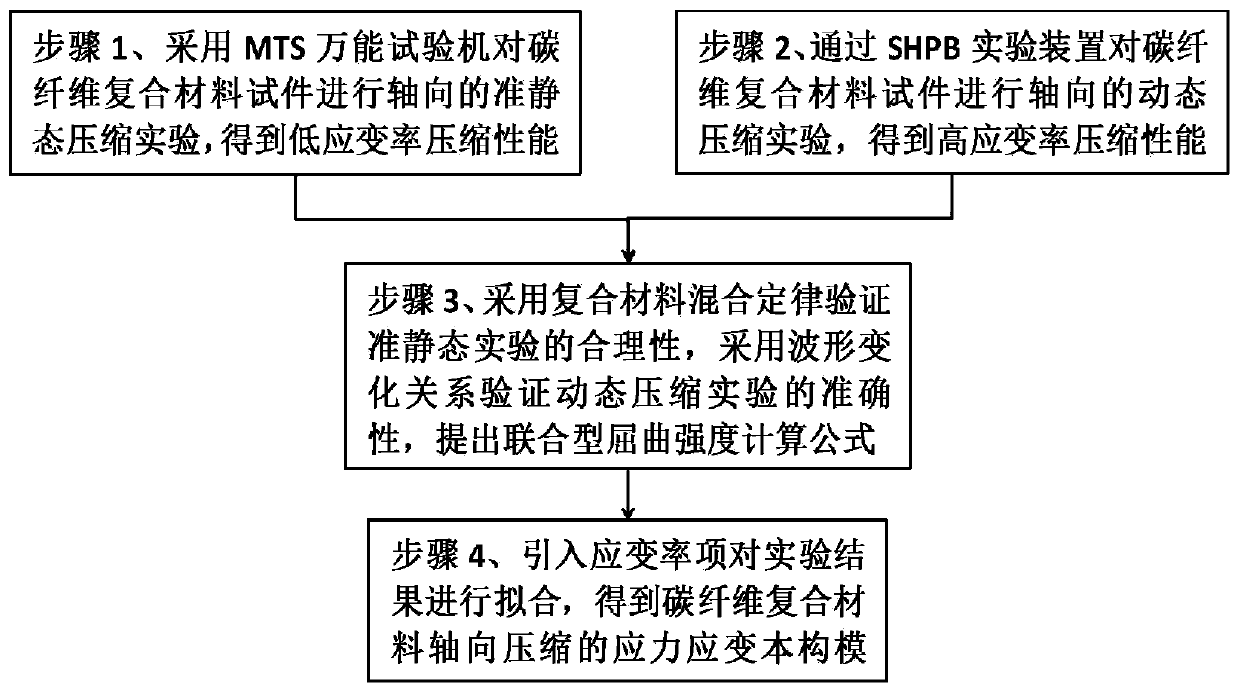

Method for testing axial compression performance of carbon fiber composite material and constitutive model

A technology of composite materials and axial compression, which is applied in the direction of analyzing materials, using stable tension/compression to test material strength, measuring devices, etc., can solve the problem of insufficient establishment of unidirectional carbon fiber compression constitutive model, constitutive model research, Unconstitutive model research and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

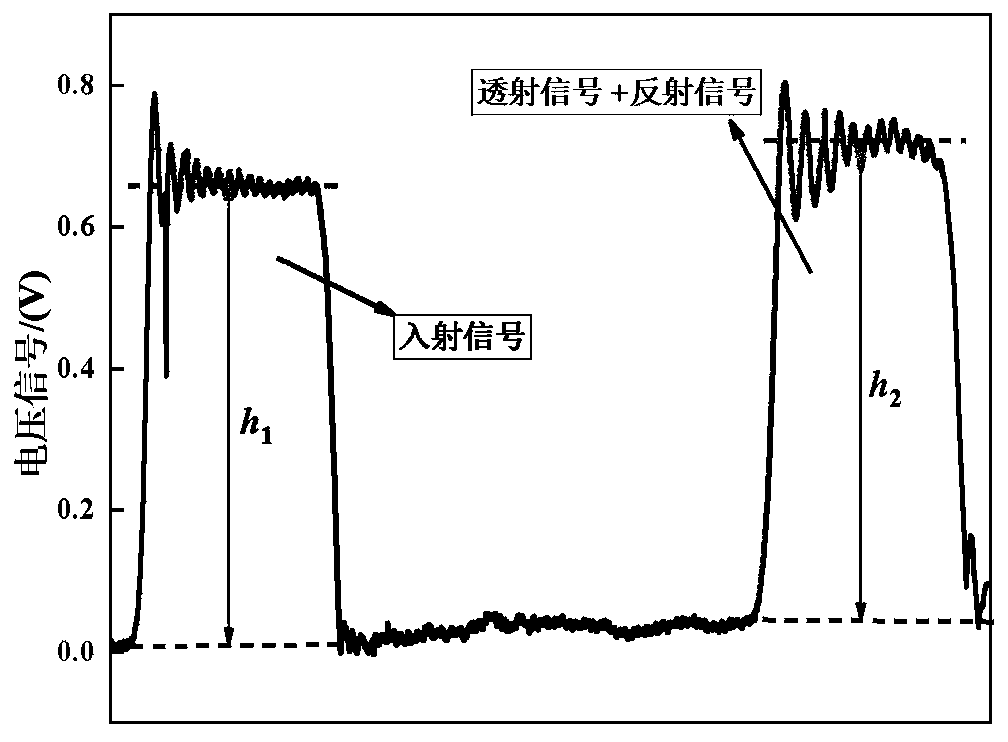

[0053] The material used in step 1 and step 2 is a carbon fiber composite material, which is formed by curing 75% of carbon fiber bundles and 25% of epoxy resin through high temperature and high pressure. The fiber is 3K / T300 polyacrylonitrile-based carbon fiber, the tensile strength is 3530MPa, the elastic modulus is 230GPa, the diameter is 7μm, and the density is 1.76g / cm 3 . The resin is E-51 epoxy resin, the elastic modulus is 1.99GPa, and the density is 1.16g / cm 3 . The rod made is a unidirectional carbon fiber reinforced epoxy resin composite material with a density of 1.55g / cm 3 . Compression samples are obtained by cutting carbon fiber rods. MTS quasi-static test: circular section diameter d=10mm, length l=10mm; SHPB dynamic compression test: circular section diameter d=10mm, length l=5mm.

[0054] Quasi-static compression and SHPB dynamic compression results see figure 2 . (1) Quasi-static axial compression performance: It can be seen from the figure that the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com