Annular electromagnetic pulse progressive reverse drawing forming method and device for metal sheet

A reverse deep drawing, electromagnetic pulse technology, applied in the field of material plastic forming, can solve the problems of uneven wall thickness distribution, unreasonable stress state, shallow forming depth, etc., to improve the forming limit, reduce investment costs, reduce energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

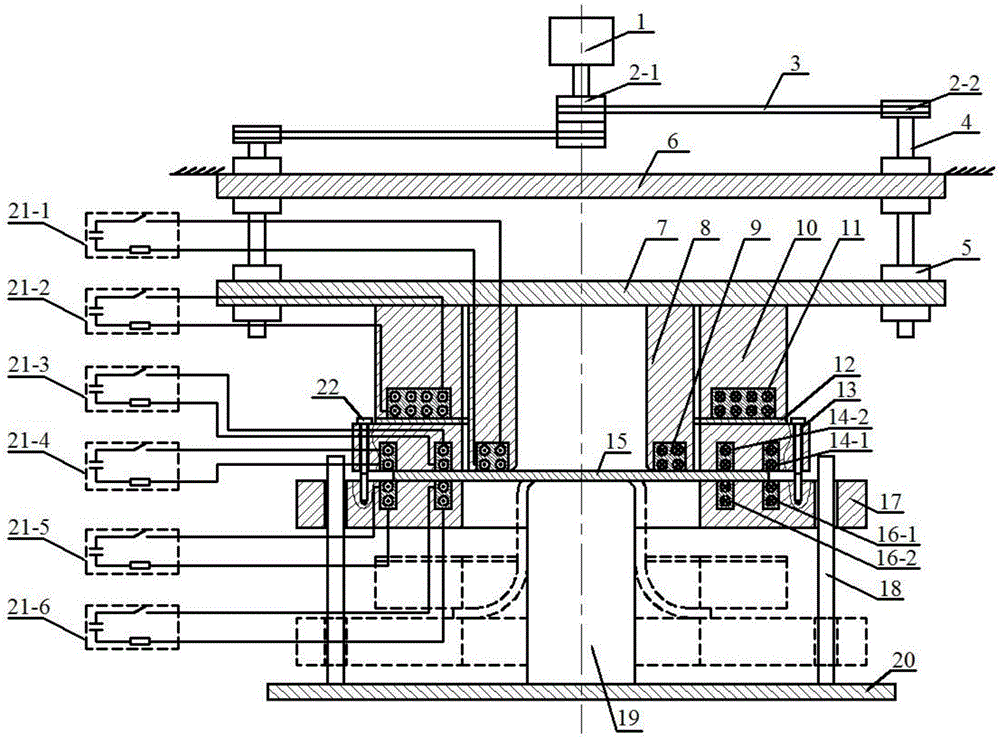

[0068] Such as figure 2 As shown, the present invention provides a ring-shaped electromagnetic pulse progressive reverse drawing forming device for metal sheets, including a die drive mechanism, a die 8, an annular deep-drawing coil 9, a splint drive mechanism, a splint 13, a bracket 17, Guide post 18, punch 19, base 20, screw 22, two booster coil groups and power supply system.

[0069] The die 8 is matched with the punch 19, the ring-shaped deep drawing coil 9 is embedded in the die 8, the guide post 18 and the punch 19 are fixedly installed on the base 20, and the splint 13 is connected with the support by four screws 22 arranged in the circumferential direction. The frame 17 is connected, the bracket 17 is sleeved on the guide post 18, and can slide up and down along the guide post 18; the splint 13 is arranged on the periphery of the die 8; the die 8 is driven by the die drive mechanism, and the The splint 13 is driven by the splint driving mechanism; the blank 15 to be...

Embodiment 2

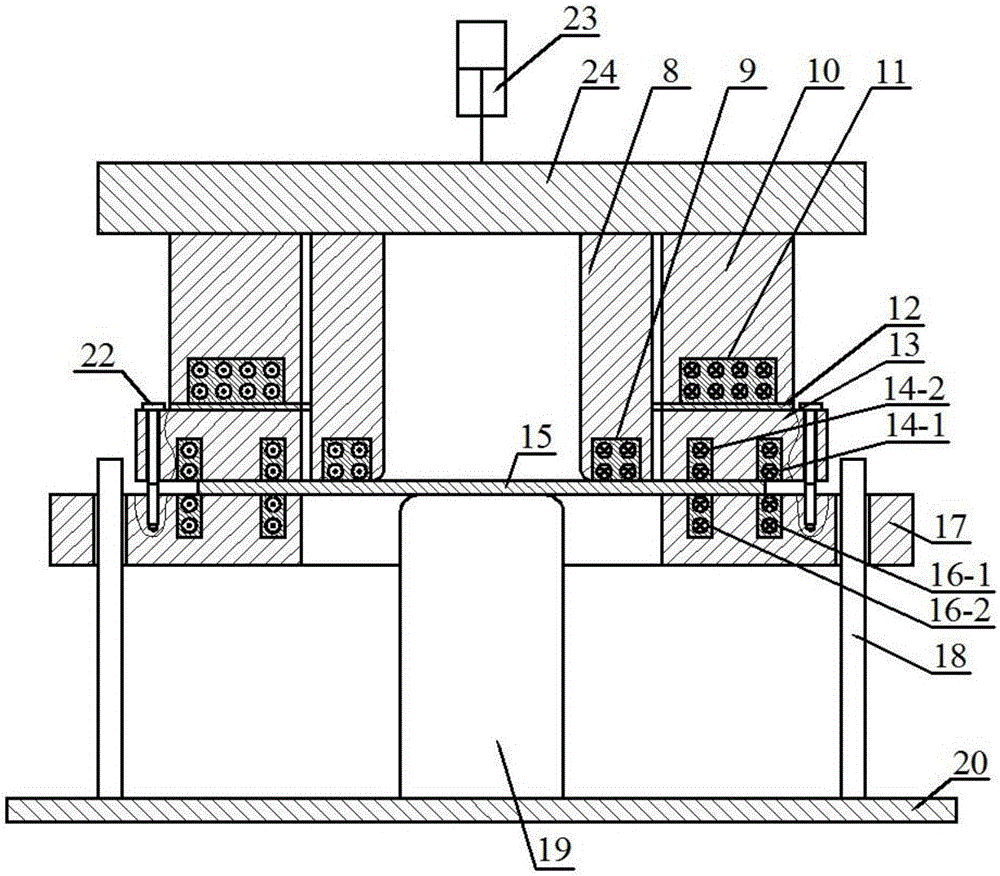

[0078] The die driving mechanism can also be realized by air / hydraulic cylinder 23 and slide block 24, such as image 3 As shown, the die 8 and the push-down coil holder 10 are fixedly installed on the lower surface of the slider 24, and the slider 24 is driven by an air / hydraulic cylinder 23. The structure of other parts and the method of reverse drawing and forming are exactly the same as those in Embodiment 1. The same, and will not repeat the description here.

Embodiment 3

[0080] Using the annular electromagnetic pulse progressive reverse drawing forming device of the metal sheet described in Embodiment 1, the method for performing reverse drawing specifically includes:

[0081] Such as Figure 11a As shown, at first the blank 15 to be formed is placed between the die 8 and the punch 19, and the blank 15 to be formed is positioned at the initial blank position 15-1 at this moment; 3. The transmission of the second pulley 2-2, screw rod 4, and nut 5 exerts downward pressure on the moving beam 7, so that the die 8 and the push-down coil seat 10 follow the moving beam 7 to go down until the bottom of the push-down coil seat 10 just touches To the upper end of the driving piece 12, in preparation for the next step of electromagnetic reverse drawing, when the die 8 is descending, the blank 15 to be formed at the bottom of the die 8 is squeezed into the gap between the die 8 and the punch 19. Gap, reversely draw the sheet material 15 to be formed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com