Micro structure hard alloy turning tool blade for cutting AISI201

An AISI201, cemented carbide technology, applied in cutting inserts, tools for lathes, turning equipment, etc., can solve problems such as insufficient micro-groove structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

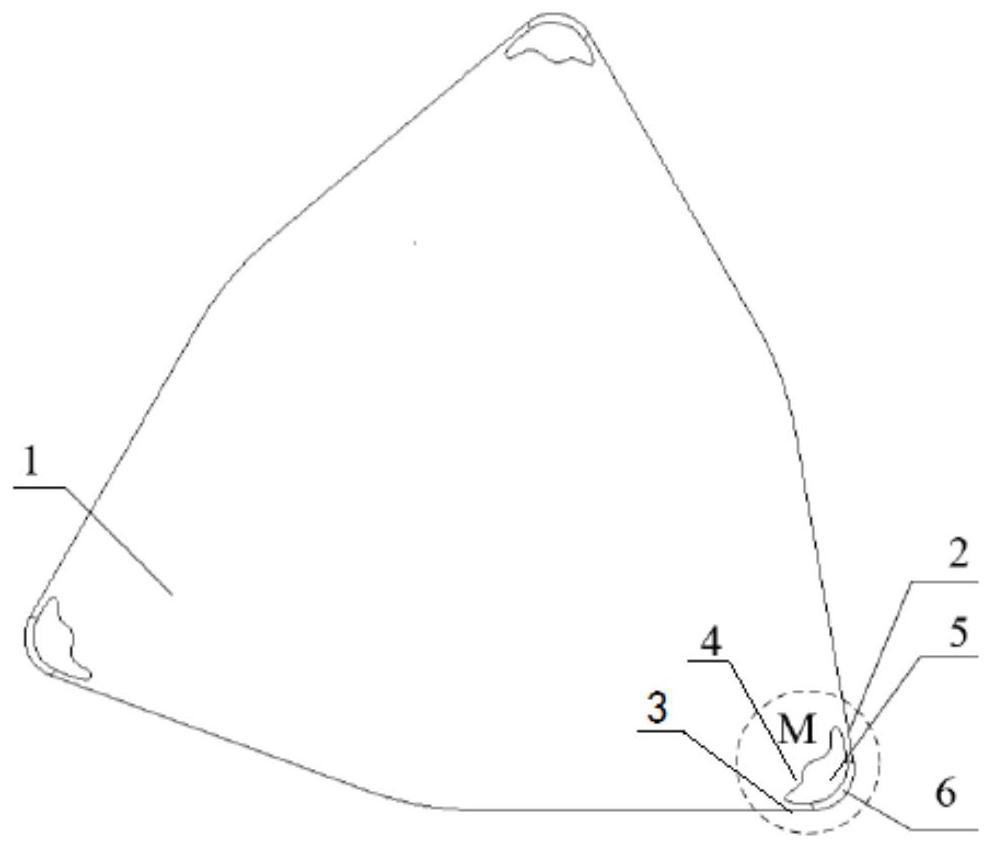

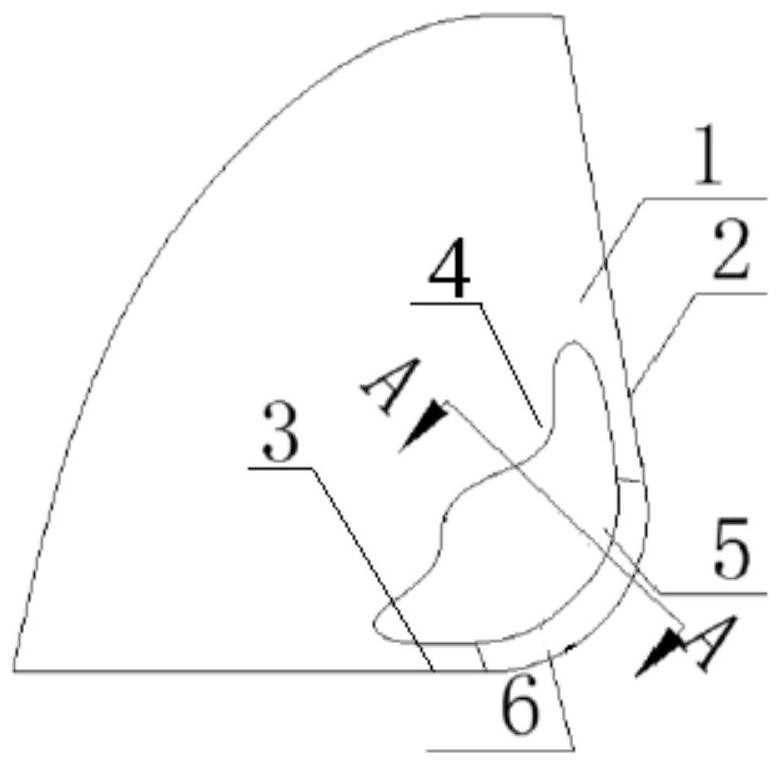

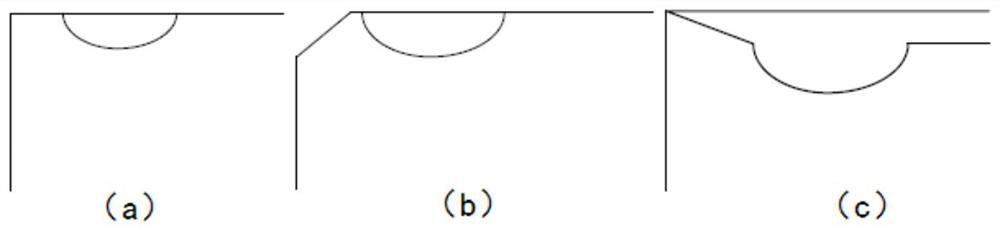

[0043] Embodiment 1: a kind of microstructure cemented carbide turning insert of cutting AISI201, as attached Figure 1-3 shown. Including the rake face 1, the sharp corner of the rake face 1 is a cutting edge 6, one side of the cutting edge 6 is the main cutting edge 2, the other side is the secondary cutting edge 3, and the inner side of the cutting edge 6 is the near region 4 of the cutting edge; The near area 4 of the cutting edge is provided with a micro-groove 5, and the micro-groove 5 is an ingot-shaped structure with asymmetry, overall unequal width and unequal depth; the maximum depth of the micro-groove 5 is 0.35mm; the micro-groove 5 The distance between the edge and the edge of the main cutting edge 2 is 0.15mm; the length of the micro-groove 5 on the main cutting edge 2 side is 3.5mm, and the length on the side of the minor cutting edge 3 is 2.5mm; the maximum width of the micro-groove 5 is 1mm. The connection forms between the outer edge of the micro-groove 5 a...

Embodiment 2

[0044] Embodiment 2: a kind of microstructure cemented carbide turning insert of cutting AISI201, as attached Figure 1-3 shown. Including the rake face 1, the sharp corner of the rake face 1 is a cutting edge 6, one side of the cutting edge 6 is the main cutting edge 2, the other side is the secondary cutting edge 3, and the inner side of the cutting edge 6 is the near region 4 of the cutting edge; The near region 4 of the cutting edge is provided with a microgroove 5, and the microgroove 5 is an ingot-shaped structure with an asymmetrical overall unequal width and unequal depth; the section of the microgroove 5 on the rake face 1 is asymmetrical. Curve type, the bottom surface of the micro-groove 5 is a smooth transition surface; the maximum depth of the micro-groove 5 is 0.25mm; the distance between the edge of the micro-groove 5 and the edge of the main cutting edge 2 is 0.1mm; The length of the side is 2.5mm, and the length of the side close to the minor cutting edge 3 i...

Embodiment 3

[0045] Embodiment 3: a kind of microstructure cemented carbide turning insert of cutting AISI201, as attached Figure 1-3 shown. Including the rake face 1, the sharp corner of the rake face 1 is a cutting edge 6, one side of the cutting edge 6 is the main cutting edge 2, the other side is the secondary cutting edge 3, and the inner side of the cutting edge 6 is the near region 4 of the cutting edge; The near region 4 of the cutting edge is provided with a microgroove 5, and the microgroove 5 is an ingot-shaped structure with an asymmetrical overall unequal width and unequal depth; the section of the microgroove 5 on the rake face 1 is asymmetrical. Curve type, the bottom surface of the micro groove 5 is a smooth transition surface; the maximum depth of the micro groove 5 is 0.50mm; the distance between the edge of the micro groove 5 and the edge of the main cutting edge 2 is 0.18mm; the micro groove 5 is close to the main cutting edge 2- The length of the side is 3.7mm, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com