Flame-retardant paper cone for loudspeaker and preparation method thereof

A flame-retardant paper and speaker technology, which is applied in pulp beating method, papermaking, paper, etc., can solve the problem that the flame-retardant and moisture-proof performance of the paper cone cannot be guaranteed, the process of paper flame-retardant treatment is cumbersome, and it is not conducive to flexible adjustment of pulp formula and other problems, to achieve the effect of improving the strength of the paper cone, beautiful timbre and sound quality, and avoiding split vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

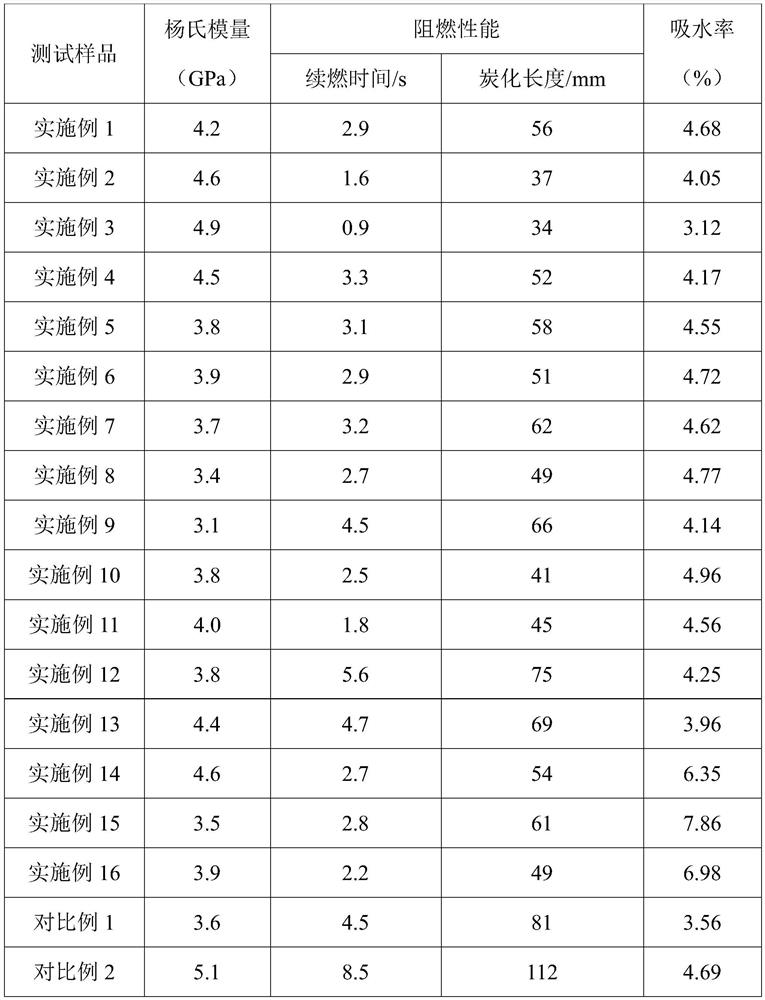

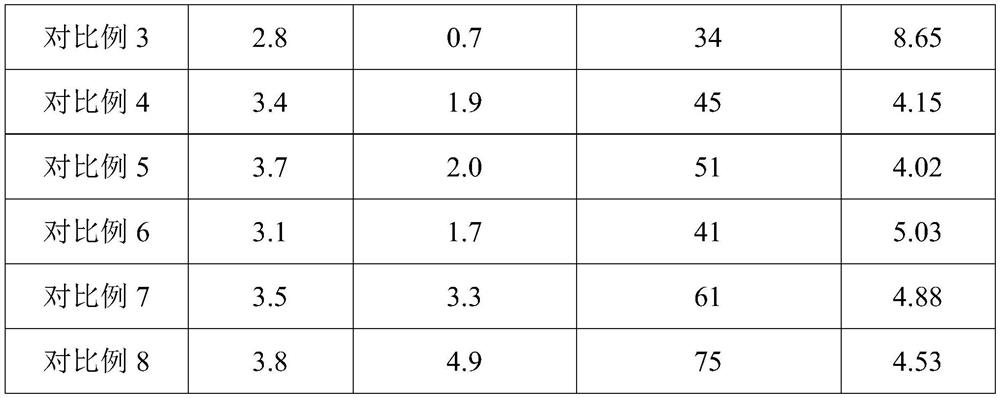

Examples

Embodiment 1

[0064] This embodiment provides a flame-retardant paper cone for a speaker, and the raw materials for preparing the flame-retardant paper cone for a speaker include, in parts by weight: 50 parts of unbleached kraft wood pulp, 45 parts of cotton pulp, 5 parts of basalt fiber, 1 part of ammonium polyphosphate and 1 part of DJ-17 hardener.

[0065] The preparation method of the flame-retardant paper cone for a loudspeaker described in this embodiment specifically includes the following steps:

[0066] (1) Beating: after crushing the pulp boards of unbleached kraft wood pulp and cotton pulp, place them in a beater, add water to dilute, and beat to obtain a pulp with a beating degree of 15°SR;

[0067] (2) papermaking: the slurry obtained in step (1) is mixed with basalt fiber, diluted with water to obtain a fiber suspension, and then the fiber suspension is filtered to obtain a paper basin embryo;

[0068] (3) Hot pressing: the paper cone blank obtained in step (2) is placed in a...

Embodiment 2

[0073] This embodiment provides a flame-retardant paper cone for a speaker, and the raw materials for the preparation of the flame-retardant paper cone for a speaker include in parts by weight: 60 parts of unbleached kraft wood pulp, 20 parts of cotton pulp, 20 parts of basalt fiber, 1 part of ammonium polyphosphate and 2 parts of DJ-17 hardener.

[0074] The preparation method of the flame-retardant paper cone for a loudspeaker described in this embodiment specifically includes the following steps:

[0075] (1) Beating: after crushing the pulp board of unbleached kraft wood pulp and cotton pulp, place it in a beater, add water to dilute, and beat to obtain a pulp with a beating degree of 20°SR;

[0076] (2) papermaking: the slurry obtained in step (1) is mixed with basalt fiber, diluted with water to obtain a fiber suspension, and then the fiber suspension is filtered to obtain a paper basin embryo;

[0077] (3) Hot pressing: the paper cone blank obtained in step (2) is plac...

Embodiment 3

[0082] This embodiment provides a flame-retardant paper cone for a speaker, and the raw materials for preparing the flame-retardant paper cone for a speaker include, in parts by weight: 40 parts of unbleached kraft wood pulp, 50 parts of cotton pulp, 10 parts of basalt fiber, 1 part of ammonium polyphosphate and 3 parts of DJ-17 hardener.

[0083] The preparation method of the flame-retardant paper cone for a loudspeaker described in this embodiment specifically includes the following steps:

[0084] (1) Beating: After crushing the pulp board of unbleached kraft wood pulp and cotton pulp, place it in a beater, add water to dilute, and beat to obtain a pulp with a beating degree of 18°SR;

[0085] (2) papermaking: the slurry obtained in step (1) is mixed with basalt fiber, diluted with water to obtain a fiber suspension, and then the fiber suspension is filtered to obtain a paper basin embryo;

[0086](3) Hot pressing: the paper cone blank obtained in step (2) is placed in a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Continue burning | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com