Preparation method of mutton-smell-free mutton fat oil

A technology for suet oil and mutton smell, which is applied in the direction of fat oil/fat refining and fat production, which can solve the problems of harsh production and operation environment, low sales volume, and restrictions on the development of suet oil, and achieve the effect of reducing free fatty acid content and mutton smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

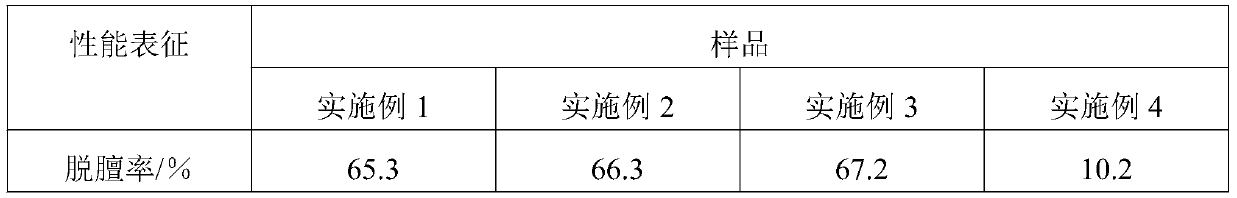

Examples

preparation example Construction

[0025] Such as figure 1 As shown, the preparation method of the no-smelly suet oil according to the embodiment of the present invention comprises:

[0026] S1. After taking the essential oil as the core material, the composite wall material is used to prepare phase change microcapsule particles;

[0027] S2, loading the phase-change microcapsule particles into the mixed gel liquid prepared by sodium silicate solution and magnesium chloride solution, and preparing modified particles after drying;

[0028] S3. Take the mutton fat and cut it into pieces, mix it with deionized water and raise the temperature to prepare a mixed slurry;

[0029] S4. Continuously heating up the mixed slurry, heat-retaining and refining to produce oil, adding modified particles, cooling and then standing heat-preserved to prepare the odor-free suet oil.

[0030] In other words, first take the essential oil as the core material, embed it and fill it into the wall material to prepare the phase-change ...

Embodiment 1

[0048] In terms of parts by weight, weigh 45 parts of deionized water, 6 parts of gelatin, 10 parts of chitosan and 10 to 15 parts of ginger essential oil, place them in a blender, stir and mix them, and heat them in a water bath at 45°C for 10 minutes to obtain the reaction solution and adjust the pH of the reaction solution to 5.0 with 5% acetic acid by mass fraction, continue the heat preservation reaction for 25min, cool to 10°C in an ice-water bath, and then adjust the pH to 6.0 with 0.1mol / lL sodium hydroxide solution, collect the mixed solution and press The addition amount is 0.2g / g, add glutamine transaminase to the mixture, stir to mix and solidify, and ultrasonically disperse at 200W for 10min to obtain a dispersion suspension;

[0049] According to the mass ratio of 1:5, add the mass fraction of 7.2% sodium silicate to the mass fraction of 5% magnesium chloride solution, and control the dropping rate of the sodium silicate solution to 5mL / min. / L sodium hydroxide s...

Embodiment 2

[0051] In terms of parts by weight, weigh 47 parts of deionized water, 7 parts of gelatin, 12 parts of chitosan and 12 parts of thyme essential oil in a mixer, stir and mix them and place them in a water bath at 47°C for 12 minutes to obtain a reaction solution and After adjusting the pH of the reaction solution to 5.0 with 5% acetic acid by mass fraction, continue the heat preservation reaction for 27 minutes, cool down to 12°C in an ice-water bath, then adjust the pH to 6.0 with 0.1mol / lL sodium hydroxide solution, collect the mixed solution and add it according to the amount added. 0.2g / g, add glutamine transaminase to the mixture, stir to mix and solidify, and ultrasonically disperse at 250W for 12min to obtain a dispersion suspension;

[0052] According to the mass ratio of 1:5, add the mass fraction of 7.2% sodium silicate to the mass fraction of 5% magnesium chloride solution, and control the dropping rate of the sodium silicate solution to 5mL / min. / L sodium hydroxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com