Method for preparing linolenic acid-rich diglyceride by enzyme method

A technology for the preparation of diglycerides of linolenic acid and enzymatic methods, which is applied in the direction of biochemical equipment and methods, enzymes, hydrolytic enzymes, etc., can solve the problems of high yield of diglycerides, limited reuse times, and high price of lipase, and achieve Reduce production costs, increase the number of reuses, and overcome the high cost of lipase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

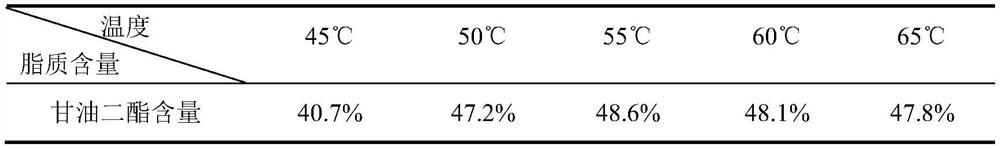

[0037] Embodiment 1: (reaction temperature optimization)

[0038] (1) The raw material is treated by reducing the peroxide value: the linseed oil with a peroxide value of 6.4mmol / kg is deodorized, and the deodorization condition is 180°C, 2mbar, 80min; kg.

[0039] (2) Synthesis of diglycerides rich in linolenic acid: add glycerol (the molar ratio of glycerol to linseed oil is 1:2) to the linseed oil treated with peroxide value reduction, and then add candida from Antarctica Yeast (Candida antarctica) lipase Lipozyme435, the amount of enzyme added is 10% (w / w, relative to the total mass of reactants), mixed together in a 50mL reactor, quickly heated to a certain temperature, reacted for 8h, and the pressure of the reaction system was controlled Below 80mbar. After the reaction is finished, recover the lipase and remove glycerol to obtain diglyceride rich in linolenic acid, and finally use HPLC to detect the content of diglyceride in the crude product.

[0040] Investigate t...

Embodiment 2

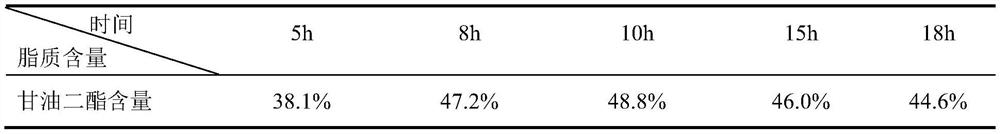

[0043] Embodiment 2: (reaction time optimization)

[0044] (1) The raw material is treated by reducing the peroxide value: the linseed oil with a peroxide value of 6.4mmol / kg is deodorized, and the deodorization condition is 180°C, 2mbar, 80min; kg.

[0045](2) Synthesis of diglycerides rich in linolenic acid: add glycerol (the molar ratio of glycerol to linseed oil is 1:2) to the linseed oil treated with peroxide value reduction, and then add candida from Antarctica Yeast (Candida antarctica) lipase Lipozyme 435, the amount of enzyme added is 10% (w / w, relative to the total mass of reactants), mixed together in a 50mL reactor, rapidly heated to 50°C, reacted for a period of time, the reaction system The pressure is controlled below 80mbar. After the reaction is finished, recover the lipase and remove glycerol to obtain diglyceride rich in linolenic acid, and finally use HPLC to detect the content of diglyceride in the crude product.

[0046] Investigate the influence of re...

Embodiment 3

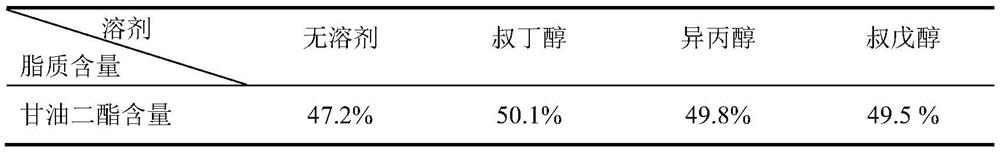

[0049] Embodiment 3: (reaction system optimization)

[0050] (1) The raw material is treated by reducing the peroxide value: the linseed oil with a peroxide value of 6.4mmol / kg is deodorized, and the deodorization condition is 180°C, 2mbar, 80min; kg.

[0051] (2) Synthesis of diglycerides rich in linolenic acid: add glycerol (the molar ratio of glycerol to linseed oil is 1:2) to the linseed oil treated with peroxide value reduction, and then add candida from Antarctica Yeast (Candida antarctica) lipase Lipozyme 435, the amount of enzyme added is 10% (w / w, relative to the total mass of the reactant), mixed together in a 50mL reactor, and added to the reactor 2 times the total mass of the substrate The organic solvent or no organic solvent was added, then the temperature was rapidly raised to 50° C., and the reaction was carried out for 8 hours. In the solvent-free reaction system, the operating pressure was controlled below 80 mbar. After the reaction, lipase was recovered a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com